Reinforced nonwoven fabric and production method thereof

A production method and enhanced technology, applied in non-woven fabrics, textiles and papermaking, etc., can solve the problems of complex production process, poor strength and low strength increase, and achieve stable technical performance, simple production process and strong practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

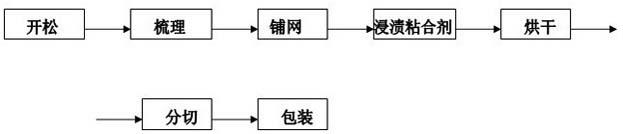

[0029] (1) Opening: The polyester staple fiber 1 is evenly sent into the cotton storage box, piled up in piles, and sent to the conventional opening equipment for loosening and dissociation, so as to achieve uniform opening.

[0030] (2) Carding: Carding the opened fibers obtained in the above step (1) on a carding machine at a speed of 12 m / min.

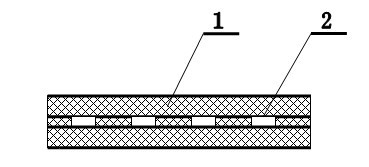

[0031] (3) Web laying: the carded fiber obtained in the above step (2) is formed into a fiber web with the required surface density under the action of a cylinder and a doffer, which are commonly used devices for conveying and carding. Add glass fiber reinforcing ribs 2 during the net laying process, and the ribs are evenly arranged at equal intervals.

[0032] (4) Saturated impregnation or foam impregnation adhesive: butyl acrylate 30kg, methyl methacrylate 70kg, N, N methylenebisacrylamide 5kg, sodium lauryl sulfate 1.5kg, OP-10 3kg, to 70kg of ionized water, 2kg of rosin soap, and 0.75kg of potassium persulfate are impregnated w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com