High-temperature cured two-component pouring sealant and preparation method thereof

A high-temperature curing, two-component technology, used in chemical instruments and methods, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of non-reuse, increased cost, environmental pollution, etc. Achieve the effect of prolonging the operation time, prolonging the service life and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

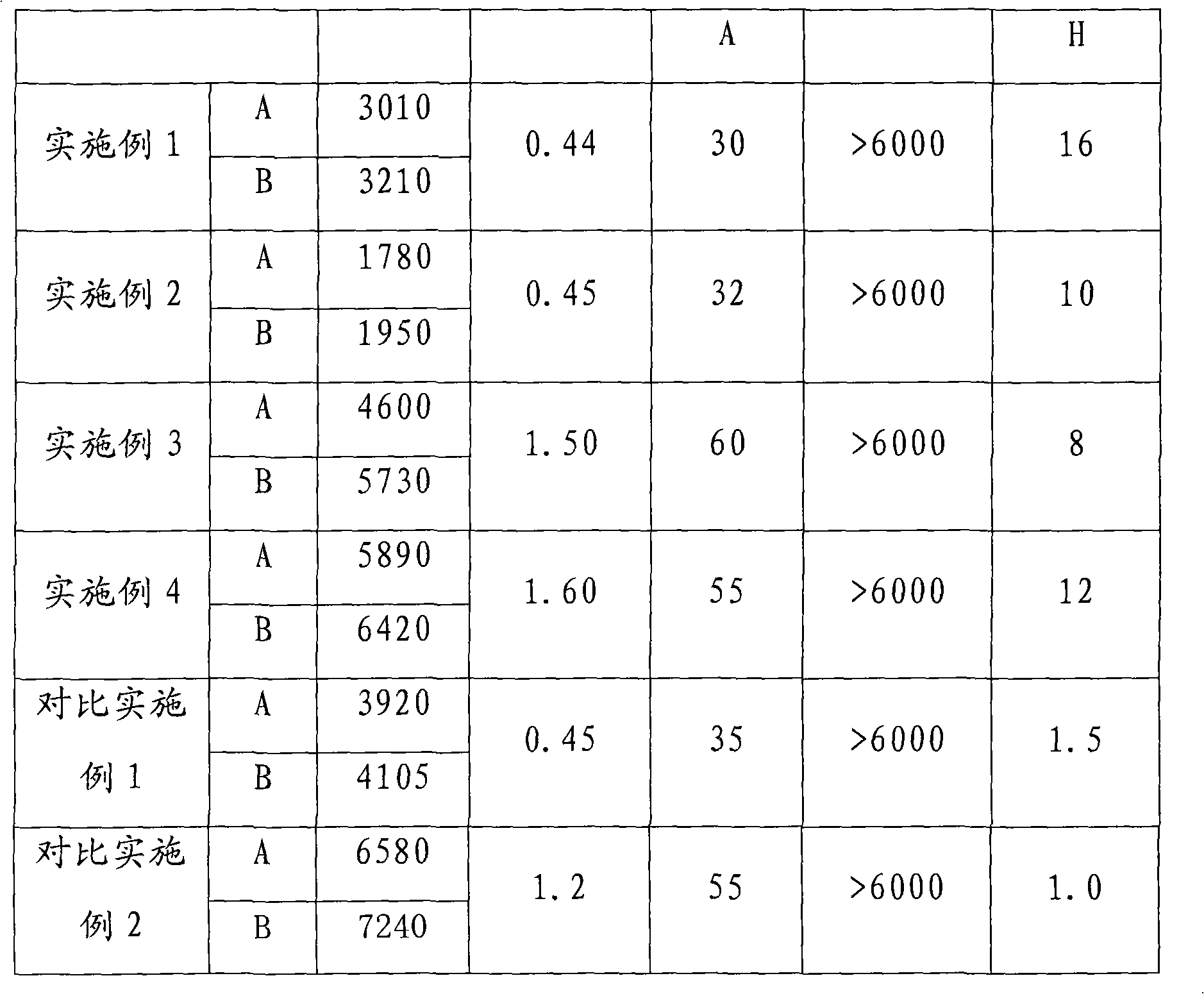

Embodiment 1

[0036] Accurately weigh 100.00g of vinyl silicone oil, 9.98g of low-hydrogen silicone oil curing agent, 0.02g of vinyl siloxane, 25.00g of aluminum hydroxide with an average particle size of 5μm, and 55.00g of spherical alumina powder with an average particle size of 40μm. g, carbon black 10g, add in the dual planetary power mixing mixer successively, in vacuum degree-0.1MPa, the rotation speed is 400 rev / min, and revolution speed is under the condition of 8 rev / min, mechanical stirring obtains component A for 1 hour, Packaged and placed for use; 108.00g of vinyl silicone oil, 2.00g of platinum catalyst with a concentration of 1000ppm, 30.00g of aluminum hydroxide with an average particle size of 5μm, and 60.00g of spherical alumina powder with an average particle In a planetary power mixing mixer, under the conditions of vacuum degree -0.1MPa, rotation speed of 400 rpm, and revolution speed of 8 rpm, mechanically stir for 1 hour to obtain component B, which is packaged and pla...

Embodiment 2

[0040]Accurately weigh 79.98g of vinyl silicone oil, 30.00g of low-hydrogen silicone oil curing agent, 0.04g of alkyneoxysilane, 30.00g of aluminum hydroxide with an average particle size of 2μm, and 50.00g of spherical alumina powder with an average particle size of 60μm. g, 10.00g of spherical alumina powder with an average particle size of 0.10μm is added to the double planetary power mixer in turn, under the conditions of vacuum degree -0.08MPa, rotation speed of 1000 rpm and revolution speed of 15 rpm Component A was obtained under mechanical stirring for 1 hour, and the package was placed for use; 109.00 g of vinyl silicone oil, 1.00 g of platinum catalyst with a concentration of 5000 ppm, 25.00 g of aluminum hydroxide with an average particle size of 2 μm, and a class with an average particle size of 60 μm 45.00g of spherical alumina powder, 10.00g of spherical alumina powder with an average particle size of 0.10μm, and 10.00g of iron red are added to the double planetar...

Embodiment 3

[0044] Accurately weigh 29.69g of vinyl silicone oil, 0.30g of low hydrogen-containing silicone oil curing agent, 0.01g of alkyneoxysilane, 18.00g of zinc oxide powder with an average particle size of 5μm, and spherical alumina powder with an average particle size of 2μm 40.00g of aluminum powder, 10.00g of spherical aluminum powder with an average particle size of 2μm, 100.00g of spherical aluminum oxide powder with an average particle size of 25μm, and 2.00g of titanium dioxide. MPa, the rotation speed is 300 rpm, and the revolution speed is 5 rpm, and mechanically stirred for 2 hours to obtain component A, which is packaged and placed for use; 29.92g of vinyl silicone oil, 0.08g of platinum catalyst with a concentration of 3000ppm, 18.00g of zinc oxide powder with an average particle size of 5μm, 50.00g of spherical alumina powder with an average particle size of 2μm, 100.00g of spherical alumina powder with an average particle size of 25μm, and 2.00g of silver powder with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com