Preparation method of solid simulation body for optical breast imaging

A breast imaging and manufacturing method technology, applied in the field of biomedical engineering, can solve the problems of confidentiality of the design method, manufacturing process, limited imaging target mode, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below according to the embodiments.

[0025] The material used in this embodiment to make the phantom consists of three parts, the base material, the absorbing material and the scattering material. The base material includes epoxy resin and curing agent; the absorbing material is near-infrared absorbing dye; the scattering material is titanium dioxide (TiO 2 ) microparticles. The materials and manufacturing methods used in this embodiment will be described in detail below.

[0026] The main materials used are as follows:

[0027] 1) Near-infrared absorbing dyes

[0028] Model: Cyanine Dye NIRD-09

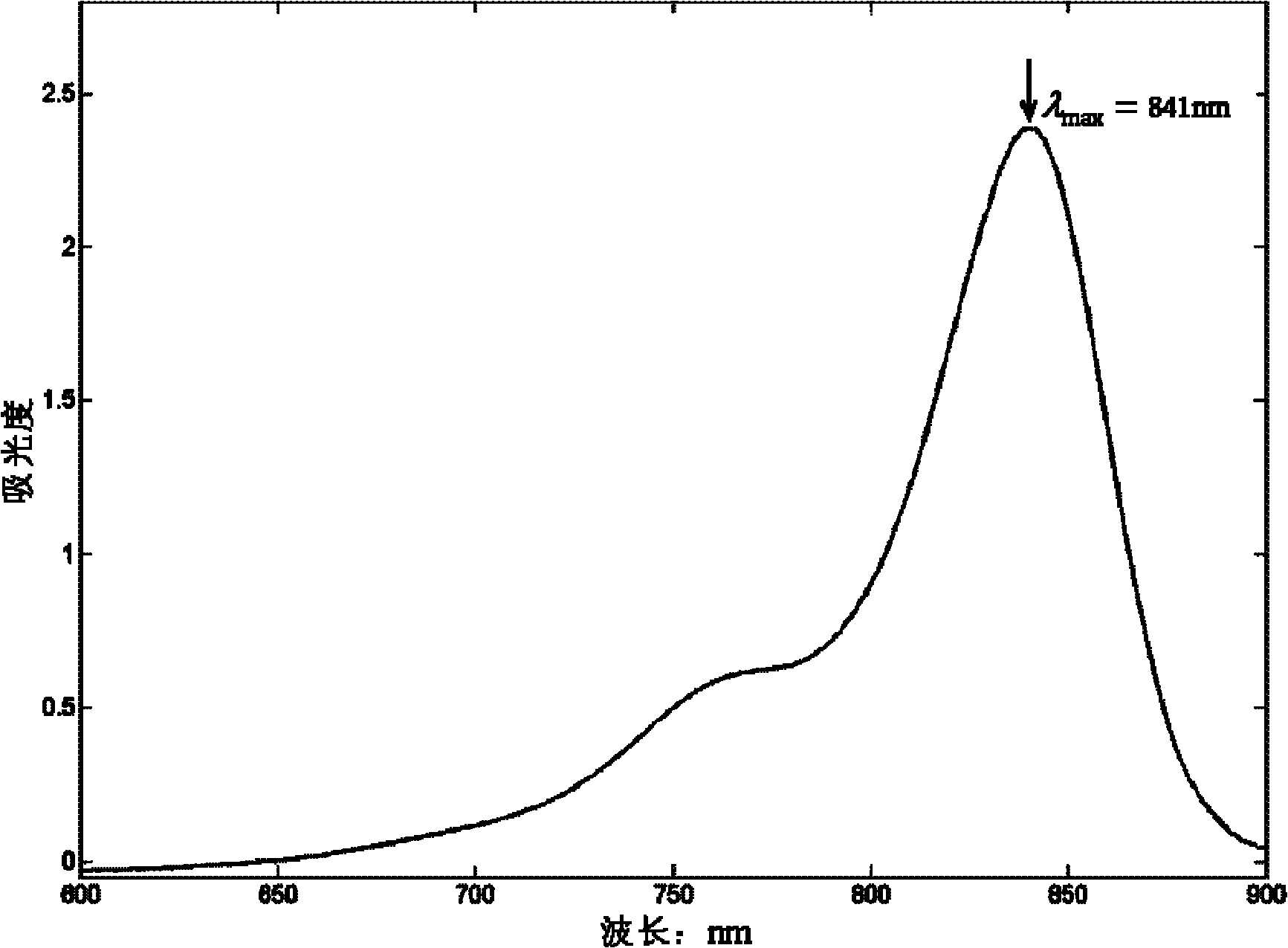

[0029] Under the condition of avoiding light, dissolve 1.5mg of dye in 100ml of epoxy resin, and stir evenly with a glass rod, which is called the absorption mother liquor. Use the spectrometer to scan the absorption spectrum curve of the absorption mother liquor (the thickness of the sample cell is 10mm) such as figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com