ABS resin material with self-cleaned surface and preparation method thereof

An ABS resin, self-cleaning technology, applied in the field of functional materials, to achieve the effect of improving mechanical properties, eliminating the trouble of cleaning and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

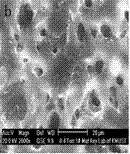

Image

Examples

Embodiment 1

[0025] Preparation of hydrophobic ABS by template method:

[0026] Feed according to the following formula:

[0027] ABS resin pellets 9.5g

[0028] Micron aluminum powder 4 grams

[0029] Nano aluminum powder 1g

[0030] By the following method:

[0031] (1) Mix the above-mentioned ABS particles with micro- and nano-aluminum powders evenly, heat them in a mosaic machine at 100°C for 30 minutes, and then heat-press them at 180°C to obtain ABS-Al plates;

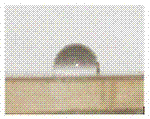

[0032] (2) Soak the ABS-Al plate in step (1) in dilute hydrochloric acid with a mass concentration of 20% for 2 minutes to dissolve the Al on the surface, and obtain an ABS-Al plate with hydrophobic properties, which is resistant to water The contact angle was 117°.

Embodiment 2

[0034] Preparation of hydrophobic ABS by template method:

[0035] Feed according to the following formula:

[0036] ABS resin pellets 99.9g

[0037] Micron aluminum powder 0.08g

[0038] Nano aluminum powder 0.02g

[0039] By the following method:

[0040] (1) Take the above-mentioned ABS particles and heat them directly in the mounting machine at 140°C for 10 minutes, and then heat-press them at 150°C to obtain ABS boards;

[0041] (2) Immediately paint a layer of micron aluminum powder and nano-aluminum powder on the surface of the ABS board in step (1), and then press it in a mounting machine at 160°C to obtain an ABS-Al board;

[0042] (3) Soak the ABS-Al plate obtained in step (2) in dilute hydrochloric acid with a mass concentration of 5% for 120 minutes, and dissolve the Al powder on the surface, and obtain an ABS-Al plate with hydrophobic properties. At this time, the ABS plate The contact angle to water is 121°.

Embodiment 3

[0044] Preparation of hydrophobic ABS by template method:

[0045] Feed according to the following formula:

[0046] ABS resin pellets 8.8g

[0047] Micron aluminum powder 0.9g

[0048] Nano aluminum powder 0.3g

[0049] By the following method:

[0050] (1) Take the above-mentioned ABS particles and mix them evenly with micro- and nano-aluminum powders, heat them in a mosaic machine at 120°C for 20 minutes, and then heat-press them at 170°C to obtain ABS-Al plates;

[0051] (2) Soak the ABS-Al plate in step (1) in dilute hydrochloric acid with a mass concentration of 10% for 60 minutes to dissolve the Al on the surface, and obtain an ABS-Al plate with hydrophobic properties, which is resistant to water The contact angle was 119°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com