Energy-saving environmental-protection thickener for mortar preblending and dry-mixing

A dry-mixed mortar, energy-saving and environmentally friendly technology, applied in the field of building materials, can solve the problems of poor freeze-thaw resistance, affecting the durability of buildings, easy to hollow out, etc., to improve the strength and durability of mortar, promote comprehensive utilization of waste resources, The effect of increasing thixotropic lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

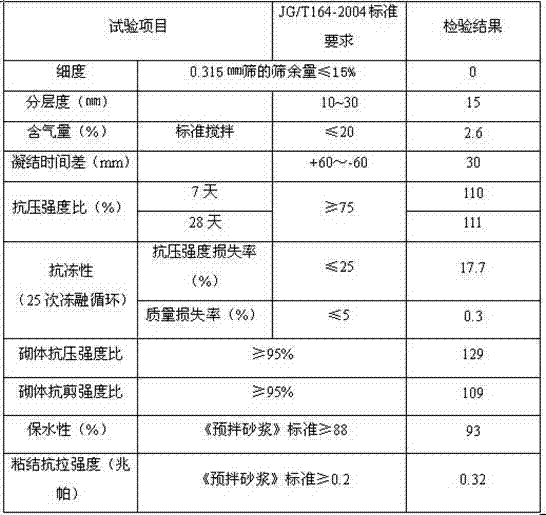

[0039] An energy-saving and environment-friendly ready-mixed dry-mixed mortar thickener. The material components of the thickener are calculated by weight percentage: 40% bentonite tailings, 15% zeolite powder, 15% fly ash, 13% slag powder, Calcium hydroxide powder 5%, gypsum powder 5% (available industrial by-product gypsum: phosphogypsum, fluorine gypsum, desulfurized gypsum), starch ether 3%, lignosulfonate 2%, polycarboxylate multi-polymer copolymer 2% . According to the set ratio, it is electronically measured, mechanically stirred by a gravity-free double-shaft mixer, and then packaged or bulk-stored.

[0040] The concrete usage method of the present invention is as follows.

[0041] For construction mortar that is stirred on site, the energy-saving and environment-friendly mortar thickener of the present invention can be added before adding water and stirring, and then add water and stir together with cement sand and other materials for 3 to 5 minutes. The dosage of e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com