Longitudinal grinding machine for welding rail welding seam

A grinding machine, longitudinal technology, applied in grinding machines, machine tools suitable for grinding workpiece edges, grinding/polishing equipment, etc. The effect of reducing the intensity of manual work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

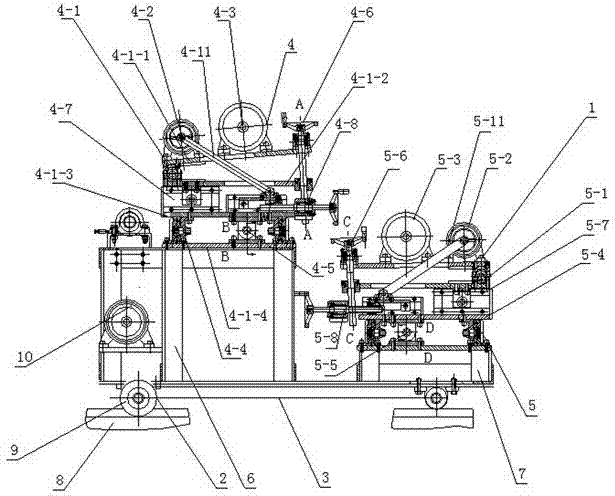

[0034] like figure 1 , a machine tool for longitudinally grinding welded rail welds, comprising a grinding machine main body 1, a driving and driving device 2 and a frame 3, the grinding machine main body 1 is divided into an upper grinding head area 4 and a lower grinding head area 5, and the frame 3 is divided into The upper grinding head installation area 6 and the lower grinding head installation area 7, the driving and driving device 2 include the wheels 9 rolling on the driving rail 8, the transverse motor 10 installed in the upper grinding head installation area 6, and the connecting wheels 9 and the transverse The transmission device 11 of the motor 10, wherein:

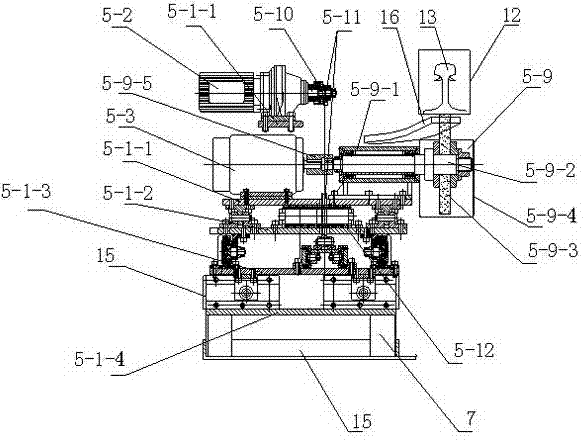

[0035] like figure 2 , the upper grinding head area 4 includes the grinding head bracket assembly A4-1 installed on the upper grinding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com