Cross chain link jewelry molding machine

A technology of jewelry forming machine and cross link, applied in clothing, watch chain, decorative chain and other directions, can solve the problems of affecting the quality of finished products, low production efficiency, cumbersome production process, etc., to reduce production costs, high degree of automation, and equipment structure. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

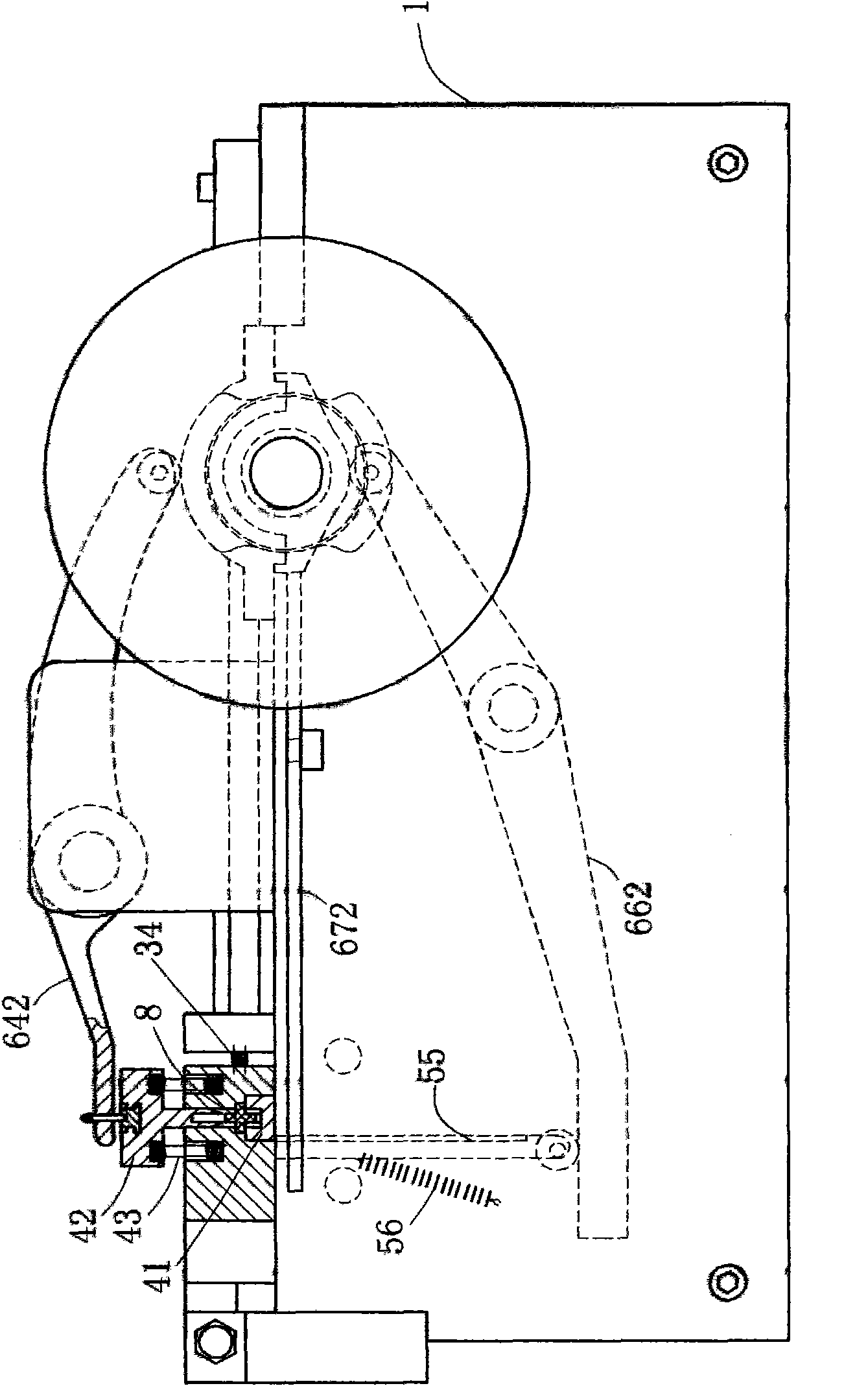

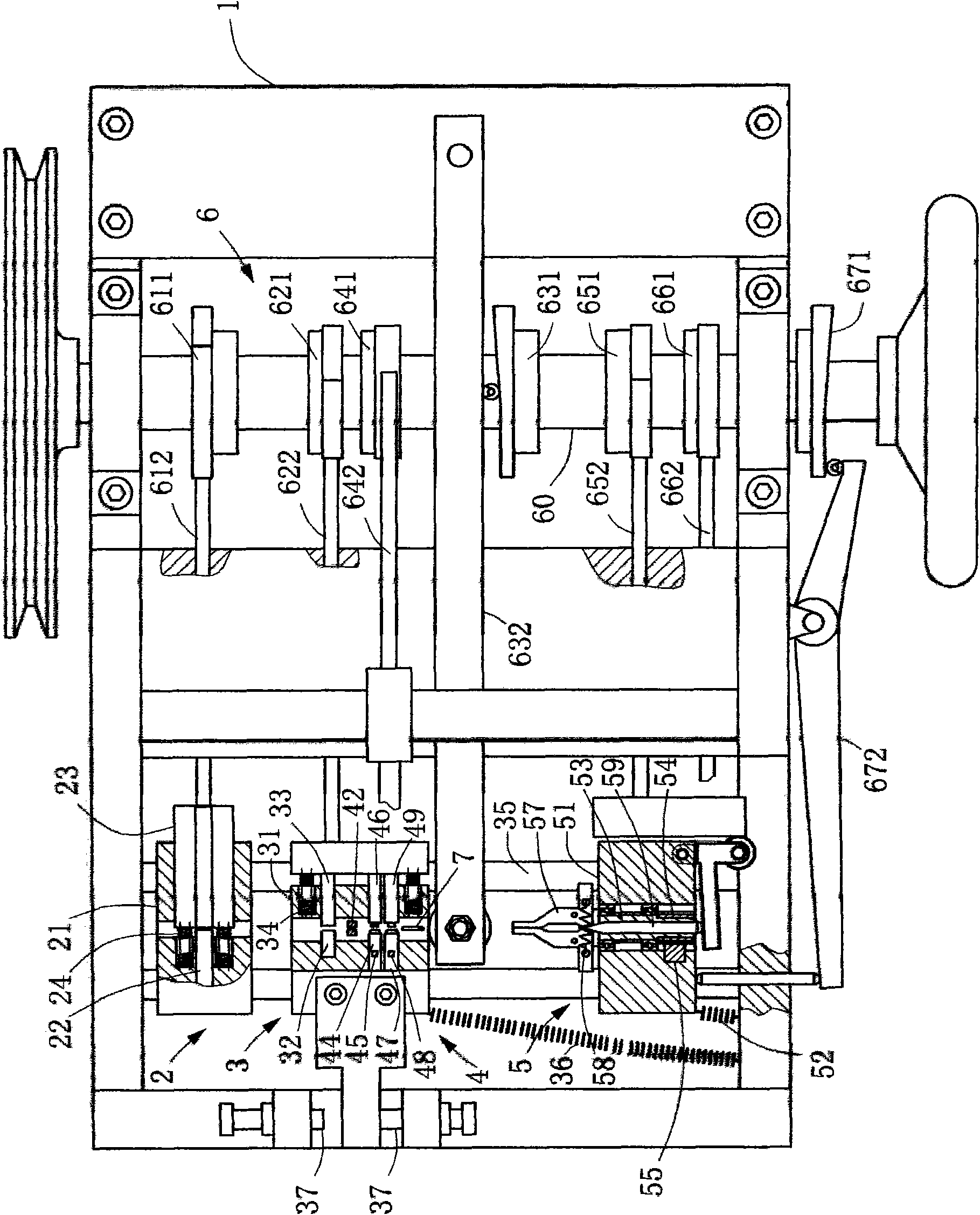

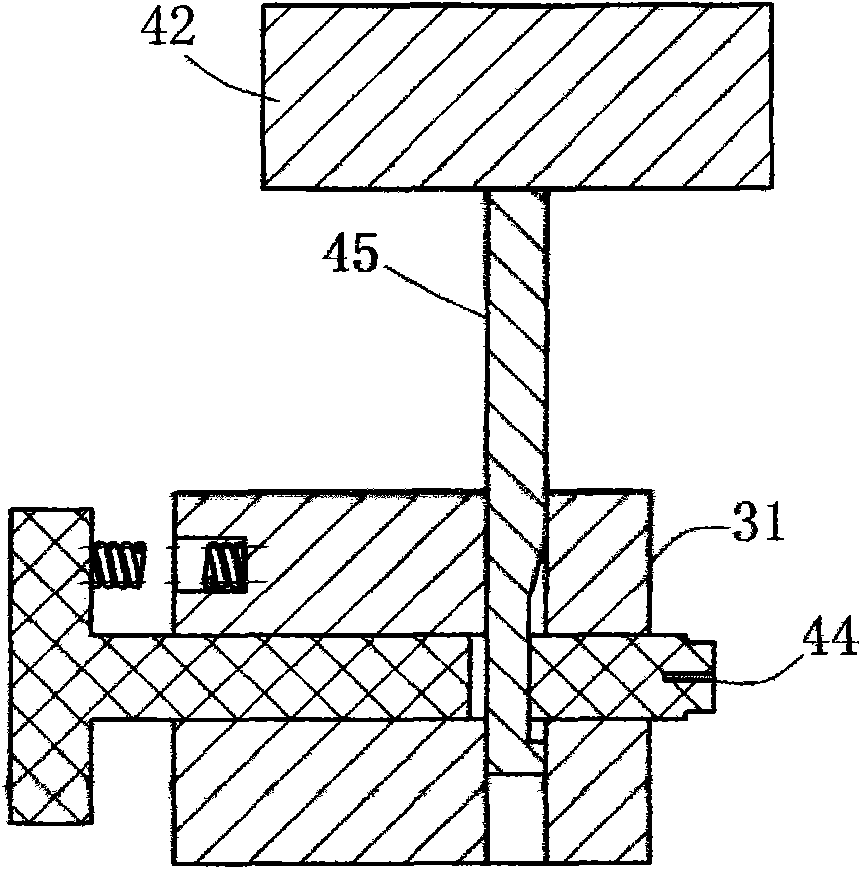

[0024] Such as figure 1 and figure 2As shown, a cross link jewelry forming machine mainly includes a frame 1, a feeding device, a progressive stamping die 4, a twisting device 5 and a driving device 6. Wherein, the feeding device is installed on the frame 1, and is used to convey the cross wire 8 to the downstream step by step; the progressive stamping die 4 is installed on the frame 1 and is located at the downstream of the feeding device position, for cutting off a section of the two sides of the cross wire 8 and punching two holes at the position without sides; the twisted flower device 5 is installed on the frame 1 And be located at the downstream position of described progressive stamping die 4, be used for clamping one end of the cross wire 8 of cutting and rotate an angle; Described driving device 6 is used for coordinating described feeding device, progressive stamping die 4 and the twisted flower device 5 act in sequence.

[0025] The feeding device mainly include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com