Method for measuring temperature of cavity of epitaxial equipment

A technology of epitaxy and equipment, applied in thermometers, thermometers with directly heat-sensitive electric/magnetic elements, measuring devices, etc., can solve problems such as inability to accurately measure temperature distribution, achieve high reliability and accuracy, and operate Simple, Data-Comprehensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

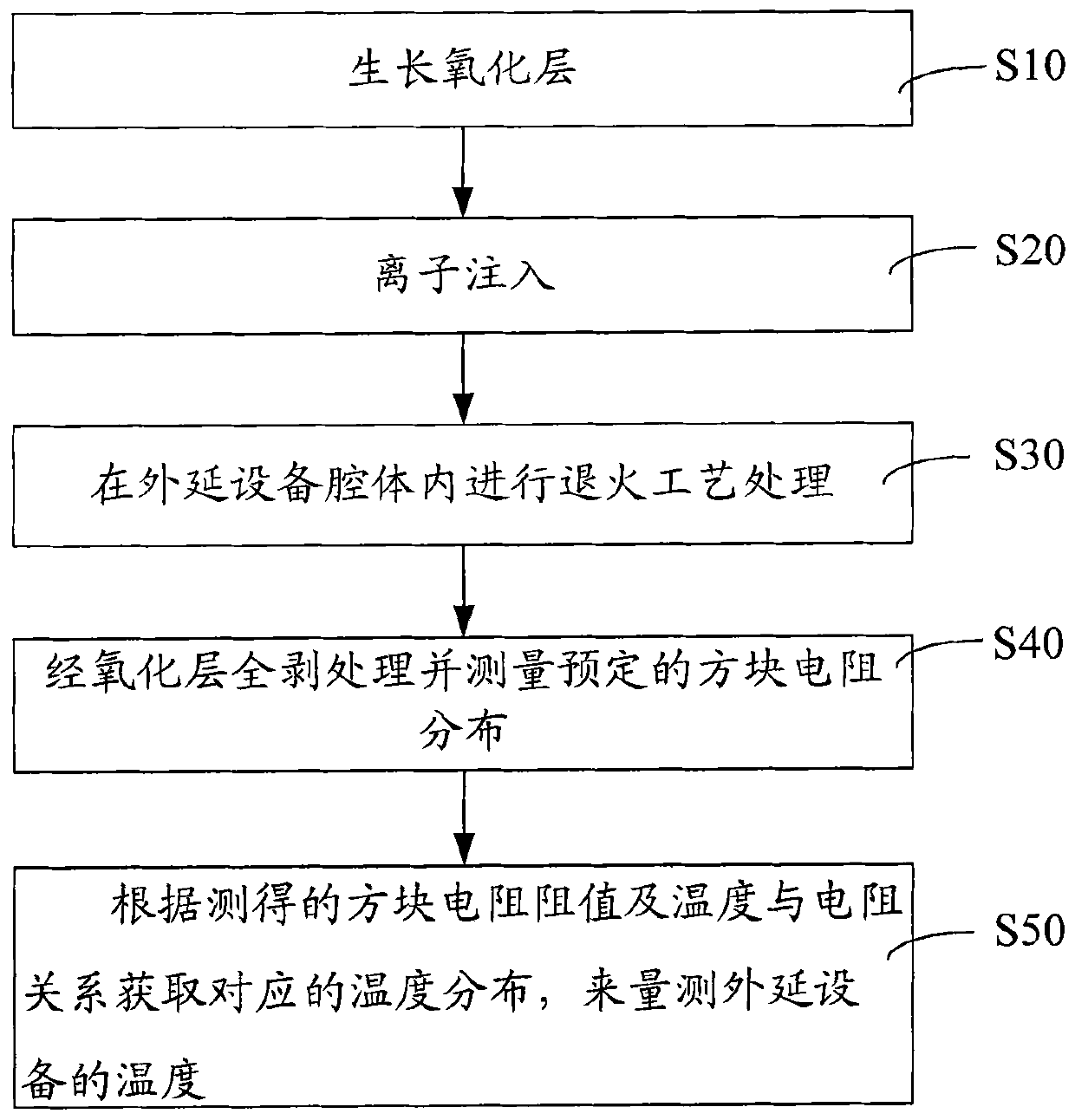

[0022] figure 1 It is a flow chart of a method for measuring the cavity temperature of an epitaxial equipment in an embodiment, including the following steps:

[0023] Step S10, growing an oxide layer.

[0024] Prepare a wafer, use a P-type sheet with a substrate resistivity of 15-25 ohm·cm, and then grow an oxide layer on the wafer. The thickness of the oxide layer can be In this embodiment, the thickness of the oxide layer is

[0025] Step S20, ion implantation.

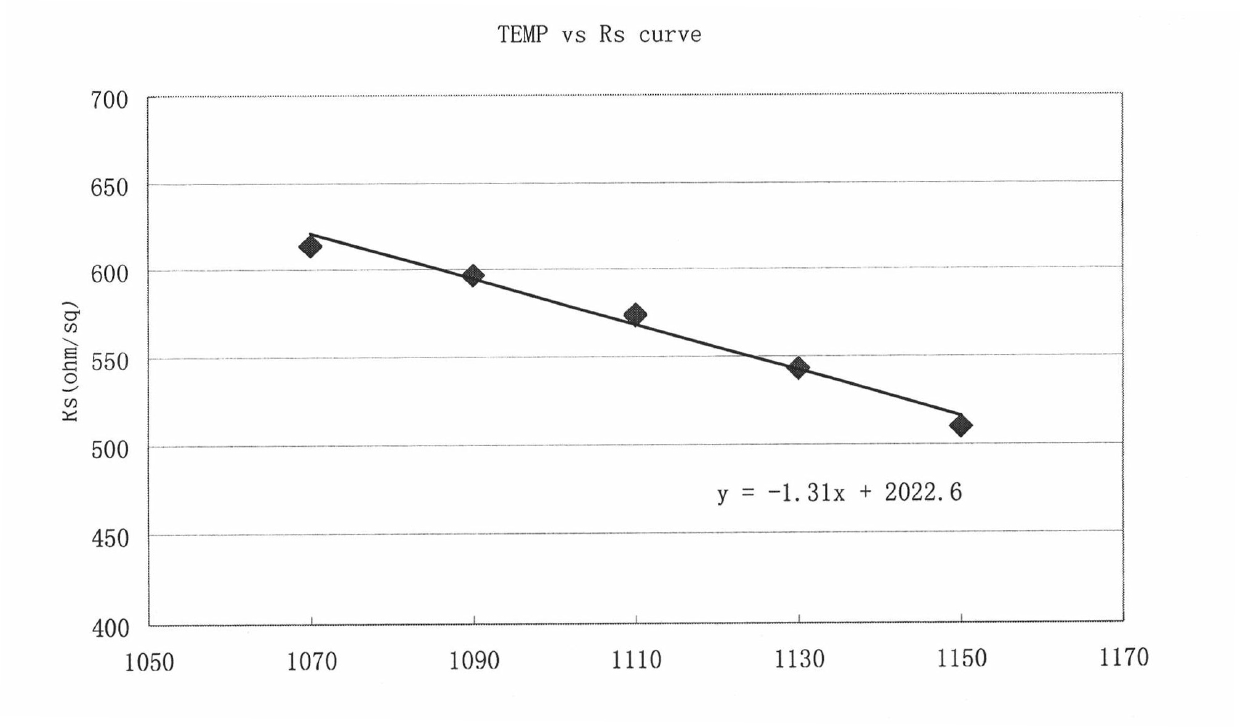

[0026] Ion implantation is performed on the wafer on which the oxide layer has been grown. Because P+ ions are implanted on the high-resistance substrate, the P+ ions are activated to release electrons e- during the high temperature process. The higher the temperature is, the more electrons e- are released, and the lower the sheet resistance. In one embodiment, when performing P+ ion implantation, the energy is 80 kiloelectron volts (KeV), and the dose / concentration is 6×10 per square centimeter. 13 atoms,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com