Organic aluminum phosphate fire retardant and preparation method and use thereof

A technology of organic phosphonic acid and flame retardant, which is applied in the direction of fireproof coatings, etc., can solve the problem of not having a large amount, and achieve the effects of convenient operation, good thermal stability, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

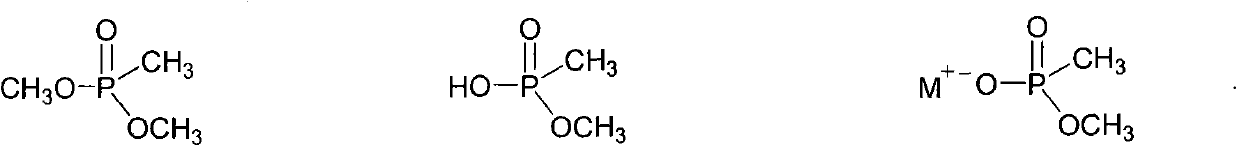

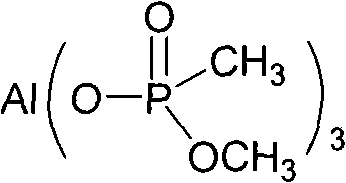

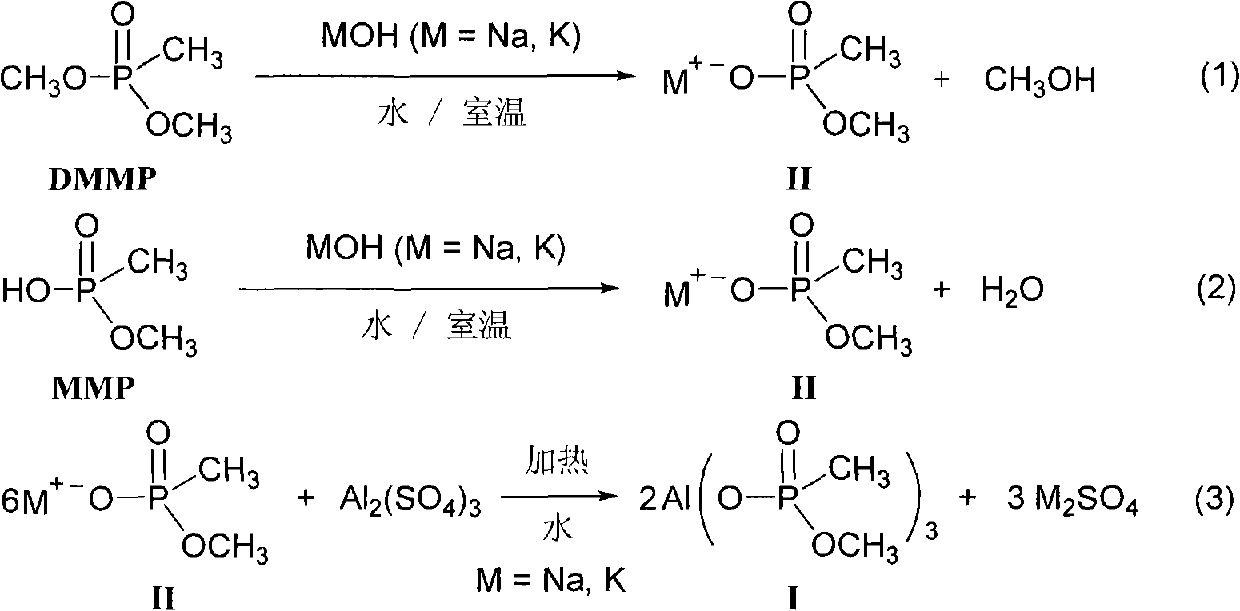

Method used

Image

Examples

Embodiment 1

[0032] The first step: add dimethyl methylphosphonate (DMMP) (372.3g, 3.0mol) successively in a 3000mL three-neck round bottom flask equipped with mechanical stirring, tap water condenser and constant pressure dropping funnel Sodium (120.0 g, 3.0 mol) and 1500 mL of water were prepared with a 2 mol / L aqueous sodium hydroxide solution, stirred at room temperature for 6 hours to obtain an aqueous solution of methyl methylphosphonate (MMP) sodium salt II.

[0033] The second step: add aluminum sulfate octadecahydrate (333.2g, 0.5mol) and 500mL water in a 5000mL four-necked round bottom flask equipped with mechanical stirring, tap water condenser, built-in thermometer and constant pressure dropping funnel, and stir dissolve. The aqueous solution of MMP sodium salt II obtained from the first step reaction was added to it in batches within 3 hours, and the temperature of the oil bath was raised to 90°C during the addition. Then the oil bath was heated up to 110° C., and the reactio...

Embodiment 2

[0036] The first step reaction is the same as in Example 1, and the difference from Example 1 is that the second step is reacted for 7 hours to obtain 299g of the target product I, and the yield is 84.5%.

Embodiment 3

[0038] The first step reaction is the same as in Example 1, and the difference from Example 1 is that the second step is reacted for 10 hours to obtain 300g of target product I with a yield of 84.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com