Method for preparing cyclosporine A

A technology of cyclosporin and fermented liquid, which is applied in the field of biomedicine, can solve the problems of poor pigment removal effect, many types of organic solvents, complex processes, etc., achieve significant concentration and enrichment, reduce energy consumption and labor intensity, and use less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

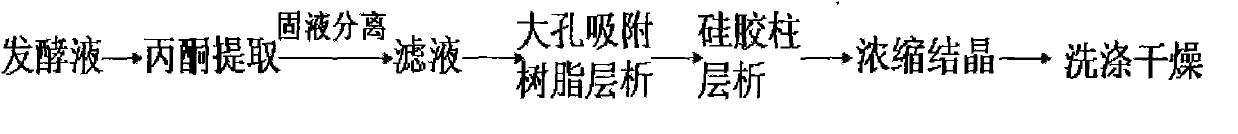

Method used

Image

Examples

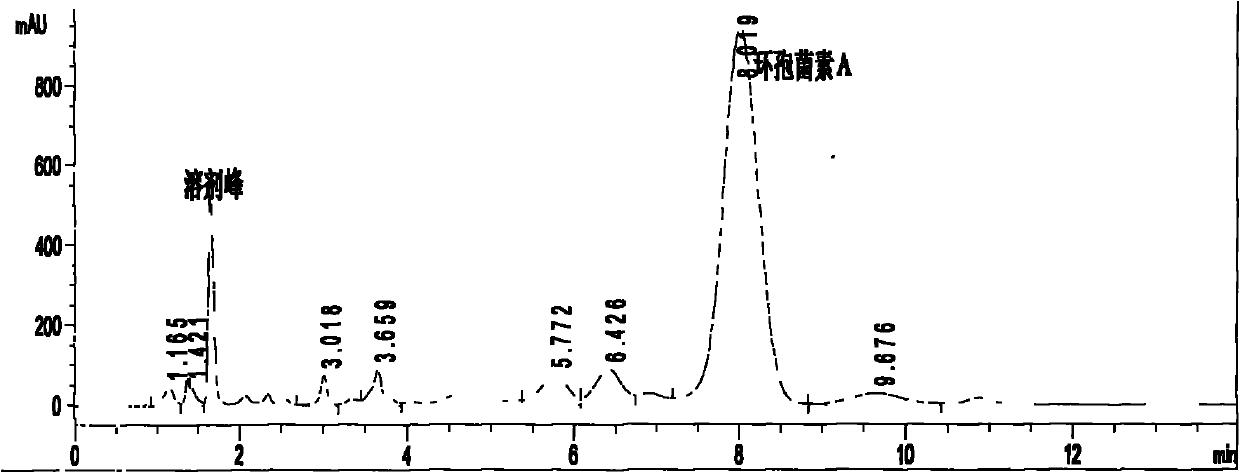

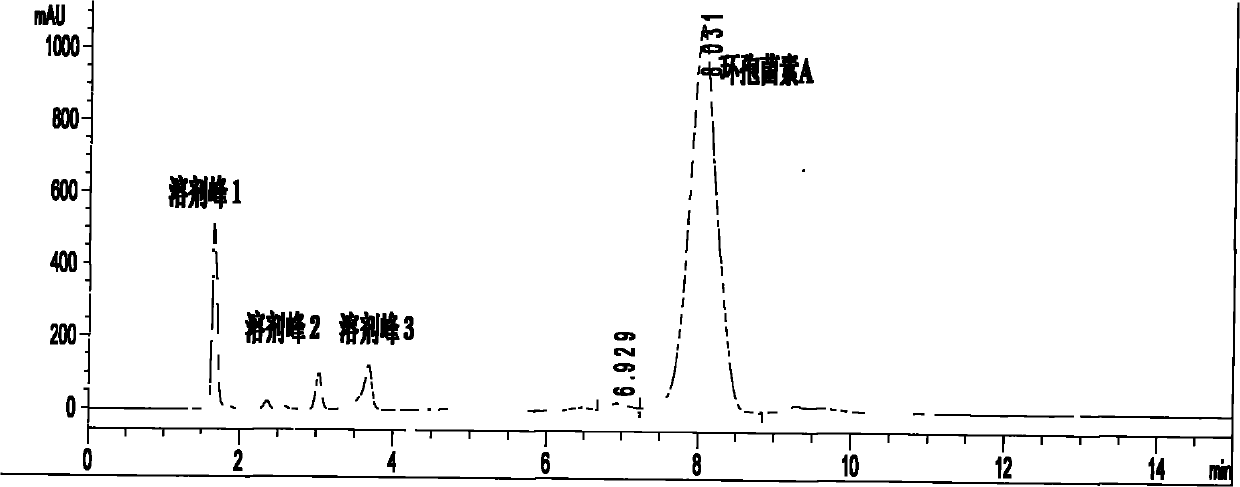

Embodiment 1

[0033] (1) Take 50L of cyclosporin A fermentation broth, add 5mol / l NaOH to adjust the pH to neutral, add 1 volume of acetone and stir and extract at 30°C for 8 hours, vacuum filter at -0.06Mpa to remove the bacteria, and collect the filtrate to be Upper column.

[0034] (2) Pack a column (Ф10cm×120cm) with 5kg D101 macroporous adsorption resin, wash and process the resin with pure water, 3% sodium hydroxide solution and 3% hydrochloric acid solution respectively, and extract about 10 times the column volume Put on the column; wash the column with about 2 column volumes of 3% hydrochloric acid and wash it with pure water to pH 6.5-7.5; elute with acetone, collect about 1.5 times the column volume eluate; add 0.5 times the volume of petroleum in the eluent The layers were separated by ether extraction, the lower aqueous phase was removed, and the upper liquid phase was concentrated to be applied to a silica gel column.

[0035] (3) Appropriately treat 200-300 mesh silica gel a...

Embodiment 2

[0038] (1) Take 50L of cyclosporine A fermentation broth, add 5mol / l NaOH to adjust the pH to neutral, add 2 times the volume of methanol and stir and extract at 40°C for 5 hours, vacuum filter at -0.06Mpa to remove the bacteria, and collect the filtrate to be Upper column.

[0039] (2) Pack the column with 5kg H103 macroporous adsorption resin (Ф10cm×120cm), wash and treat the resin with pure water, 3% sodium hydroxide solution and 3% hydrochloric acid solution respectively, and put about 8 times column volume extract on the Column, wash the column with 1.5 times the column volume of 3% hydrochloric acid and wash it with pure water to pH 6.5-7.5, elute with ethyl acetate, collect about 2 times the column volume eluate, add 0.5 times the volume of petroleum to the eluate The layers were extracted with ether, the lower aqueous phase was removed, and the upper liquid phase was concentrated to be applied to a silica gel column.

[0040] (3) This step is the same as step (3) in E...

Embodiment 3

[0043] (1) Take 50L of cyclosporine A fermentation broth, add 5mol / l NaOH to adjust the pH to neutral, add 1.5 times the volume of ethyl acetate, stir and extract at 35°C for 6 hours, remove the bacteria by vacuum filtration at -0.06Mpa, and collect The filtrate was loaded onto the column.

[0044] (2) Pack the column with 5kg X-5 macroporous adsorption resin (Ф10cm×120cm), wash the resin with pure water, 3% sodium hydroxide solution and 3% hydrochloric acid solution respectively, and extract about 7 times the column volume after treatment Liquid on the column; wash the column with 2 times the column volume of 3% hydrochloric acid and wash it with pure water to pH 6.5-7.5; elute with acetone, collect about 1.5 times the column volume eluate; add 0.5 times the volume of petroleum in the eluent The layers were extracted with ether, the lower aqueous phase was removed, and the upper liquid phase was concentrated to be applied to a silica gel column.

[0045] (3) This step is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com