Method for preparing xylo-oligosaccharides by adopting steam explosion and oriented enzymolysis

A technology of xylo-oligosaccharide and directional enzymolysis, applied in the direction of fermentation, can solve the problems of inability to directionally degrade xylo-oligosaccharide, increase the load of xylo-oligosaccharide production and refining process, etc. Consistency and economic efficiency, the effect of simplifying the extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

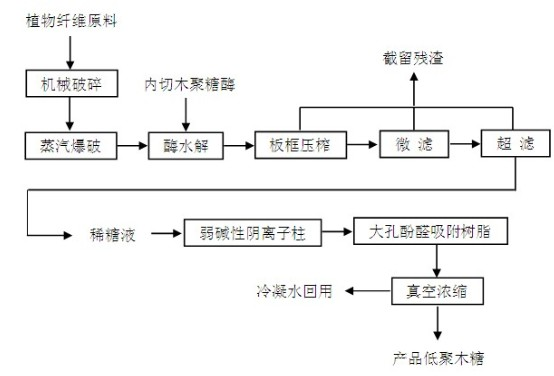

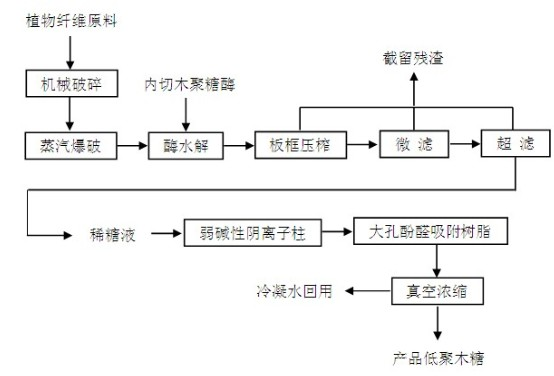

[0030] Air-dried corncobs are pretreated by manual sorting to remove mold, vibrating screen for sand removal and iron removal, and then mechanically crushed until the length of the particles does not exceed 50mm and the diameter does not exceed 20mm.

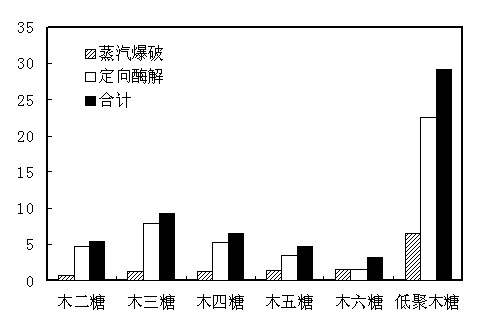

[0031] Add materials to the intermittent or continuous automatic steam blaster, open the steam inlet valve through the automatic control system and directly pass in 2.0MPa supersaturated steam to quickly heat the materials to 200~205°C, and automatically open the discharge valve instantaneously after maintaining for 3~8min Create a blasting effect and get blasting material. The blasting material was tested, and the recovery rate of the total solids of the blasting material reached over 80.0%, the pH value was 4.5-5.0, and the recovery rate of xylan was higher than 70.0%, of which soluble xylan and xylooligosaccharides accounted for 36.0% ~38.0%, the yield of xylo-oligosaccharide components with a degree of polymerization of 2-6 ...

Embodiment 2

[0033] The directional enzymatic hydrolysis of blasting materials is carried out by a mechanical stirring enzyme hydrolysis device. Add an appropriate amount of soft water to adjust the total solids concentration of the blasting material to 5.0-10.0% (w / w), add endoxylanase according to the amount of 5-15U / g xylan, and control the reaction temperature at 50±2°C and The stirring rate is 50-100 rpm, and the enzymolysis solution is obtained after 20-24 hours of directional enzymolysis reaction. The enzymolysis solution was tested, and during the enzymolysis process, the enzymolysis yield of xylooligosaccharide components with a degree of polymerization of 2 to 6 exceeded 23.5%. Taking the xylan contained in the corncob steam explosion material as the calculation basis, the total yield of xylooligosaccharides with a polymerization degree of 2-6 after steam explosion and directional enzymatic hydrolysis is 30.0%.

Embodiment 3

[0035] Under the condition of 40-45°C, the plate and frame filter is used to press filter the enzymatic hydrolysis system to remove solid impurities. The inlet pressure of the plate and frame filtration operation is controlled at 1.0-1.5MPa, and the filter cake is washed with 20-25% (w / w) soft water to obtain xylo-oligosaccharide filtrate; Module (membrane pore size 0.20 ~ 0.45 μm) to filter xylooligosaccharide filtrate to obtain clarified liquid, control the operating pressure 0.15 ~ 0.20MPa; under the condition of 25 ~ 30 ℃, then use hollow fiber ultrafiltration membrane module (molecular weight cut off 20000 Dalton ) to further separate and purify the clarified liquid to obtain dilute xylo-oligosaccharide sugar liquid, and control the operating pressure to be 0.30-0.35 MPa.

[0036] Under the condition of 25 ~ 30 ℃, control the appropriate flow rate so that the dilute xylooligosaccharide liquid flows through the weakly basic anion exchange chromatography column and the macr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com