Full-water-type combined polyether and application method thereof, and polyurethane rigid foam composition

A combination of polyether and water-based technology, which is applied in the field of polyurethane rigid foam foaming, can solve the problems of decreased strength and cohesiveness of polyurethane foam, high ratio of combined polyether and isocyanate, loss of strength and cohesiveness, etc. problem, to achieve the effect of good adhesion, good bonding performance, and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

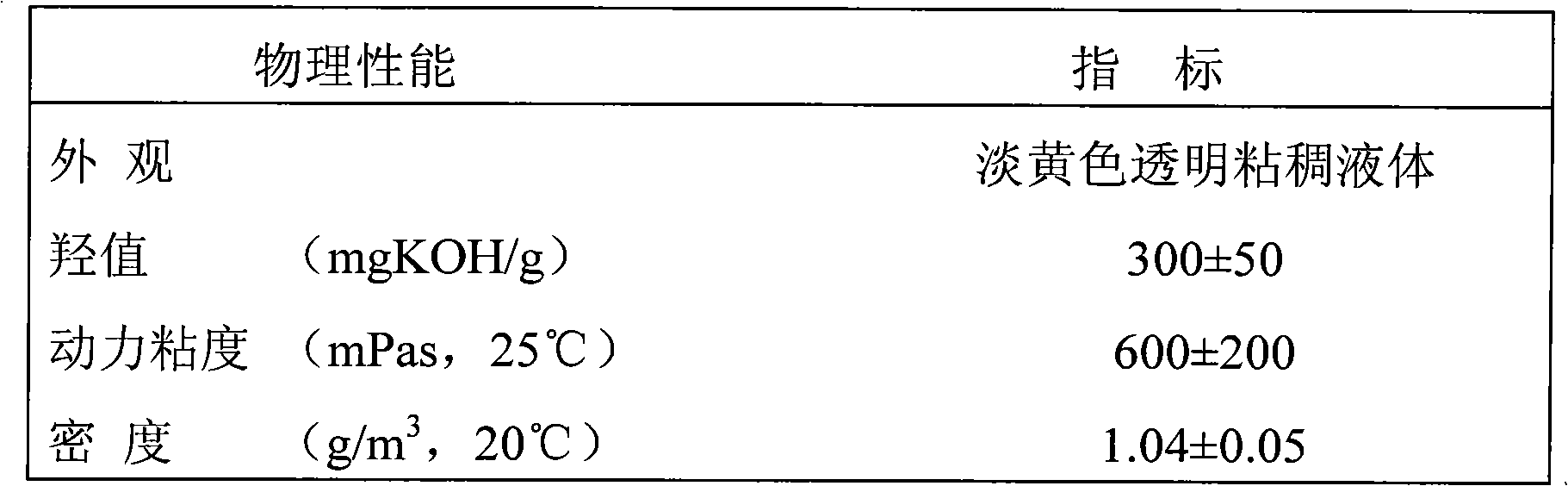

[0032] The formula of all water type combined polyether:

[0033] 6 parts of polyether polyol SA380, 4 parts of polyether polyol 310, 0.2 parts of silicone foam stabilizer B8462, 0.2 parts of N, N-dimethylcyclohexylamine, 0.1 parts of N, N-dimethylbenzylamine part, 0.4 part of water.

[0034] The preparation method of the all-water type composite polyether: according to the formula of the all-water type composite polyether, stir the above-mentioned components at room temperature at 500 rpm for 2 hours, and then discharge the materials.

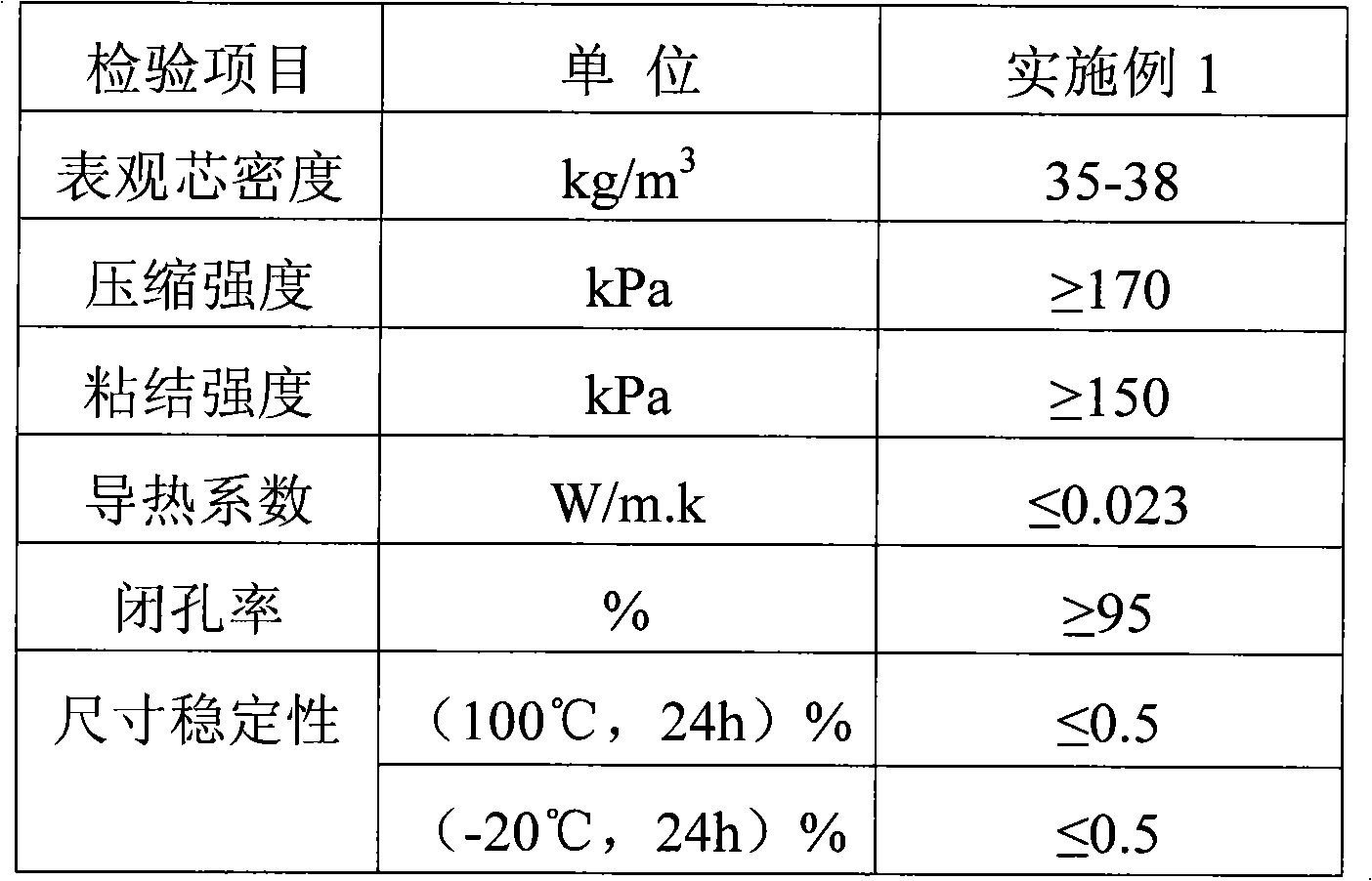

[0035] Preparation of polyurethane foam insulation material: the mass ratio of polyether product and isocyanate is 1:1.2, and the foam density is 35kg / m. 3 Polyurethane foam insulation for solar energy.

Embodiment 2

[0037] All water type combined polyether formula:

[0038] 5 parts of polyether polyol SA380, 5 parts of polyether polyol 310, 0.25 parts of silicone foam stabilizer B8462, 0.25 parts of N,N-dimethylcyclohexylamine, 0.2 parts of N,N-dimethylbenzylamine part, 0.3 part of water.

[0039] The preparation method of the all-water type composite polyether: according to the formula of the all-water type composite polyether, stir the above-mentioned components at room temperature at 500 rpm for 2 hours, and then discharge the materials.

[0040] Preparation of polyurethane foam insulation material: the mass ratio of polyether product and isocyanate is 1:1.0, and the foam density is 38kg / m. 3 Polyurethane foam insulation for solar energy.

Embodiment 3

[0042] The formula of all water type combined polyether:

[0043] 7 parts of polyether polyol SA380, 3 parts of polyether polyol 310, 0.3 parts of silicone foam stabilizer L69000, 0.3 parts of N,N-dimethylcyclohexylamine, 0.2 parts of N,N-dimethylbenzylamine parts, 0.45 parts of water,

[0044] The preparation method of the all-water type composite polyether: according to the formula of the all-water type composite polyether, stir the above-mentioned components at room temperature at 500 rpm for 2 hours, and then discharge the materials.

[0045] Preparation of polyurethane foam insulation material: the mass ratio of polyether product and isocyanate is 1:1.2, and the foam density is 37kg / m3 Polyurethane foam insulation for solar energy.

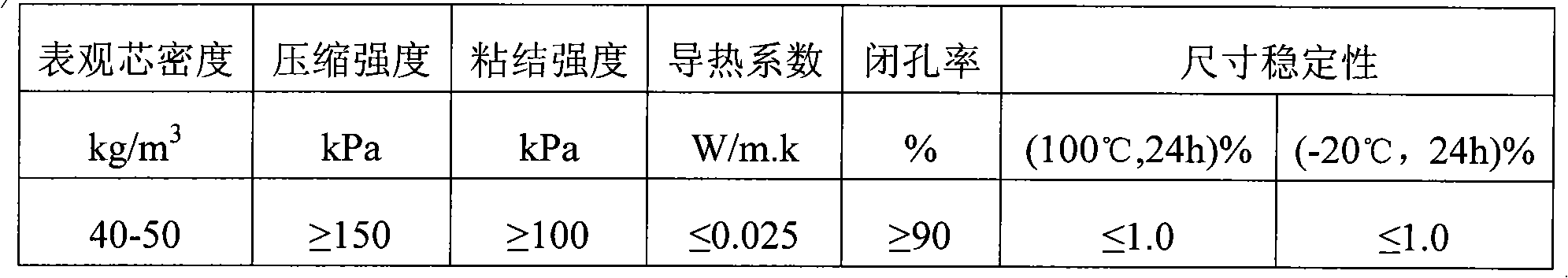

[0046] Effect Example 1 Application of all-water type combination polyether for solar energy

[0047] Add the combined polyether of Example 1 into the POL material liquid storage tank of the foaming machine, and add the polyisocyanate into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Foam density | aaaaa | aaaaa |

| Foam density | aaaaa | aaaaa |

| Foam density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com