Method for producing glass and plastic composite geogrid

A production method and composite geotechnical technology, applied in household components, applications, household appliances, etc., can solve the problems of limited engineering use range, poor interlocking ability of aggregates, poor chemical erosion, etc., to resist biological erosion and climate change, Effect of increasing tear strength and improving coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

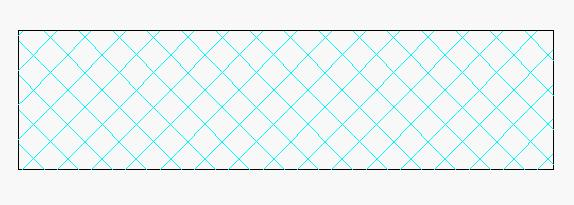

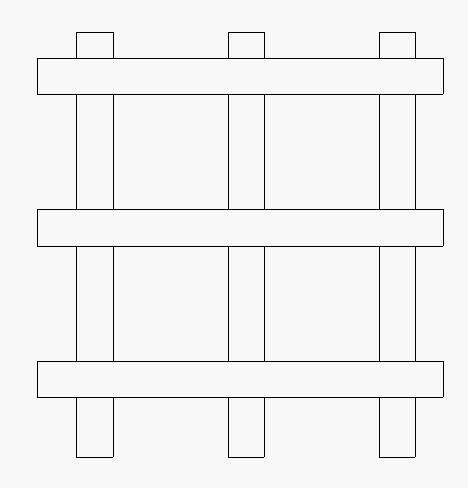

Image

Examples

specific Embodiment approach 1

[0053] Include the following steps:

[0054] a. Mix raw materials: high-density polyethylene and additives, the ratio is 2% carbon black, 3% defoamer;

[0055] b. Pass the raw materials through the extruder, the temperature of the extruder is 180°C; the glass fiber yarn is mixed by guiding co-extrusion coating, and the temperature of the co-extrusion coating mixing head is 210 °C;

[0056] c. Form a strip blank through a mold, and the mold temperature is 200°C;

[0057] d. Stretch the strip blank at 70°C; the stretching ratio is 5 times;

[0058] e. Knurling process, knurling temperature 60°C

[0059] f, counting meters into a plate;

[0060] g. Horizontal strips and longitudinal strips are fixed and pulled by steps to form a geogrid network;

[0061] h, Meter counting and winding.

specific Embodiment approach 2

[0063] A method for producing a glass-plastic composite geogrid, comprising the following steps:

[0064] a. Mix raw materials: high-density polyethylene and additives, the ratio is 4% carbon black, 3% defoamer;

[0065] b. Pass the raw materials through the extruder, the temperature of the extruder is 230°C; the glass fiber yarn is mixed by guiding co-extrusion coating, and the temperature of the co-extrusion coating mixing head is 230 °C;

[0066] c. Form a strip blank through a mold, and the mold temperature is 220°C;

[0067] d. Stretch the strip blank at 80°C; the stretching ratio is 9 times;

[0068] e. Knurling process, knurling temperature 70°C

[0069] f, counting meters into a plate;

[0070] g. Horizontal strips and longitudinal strips are fixed step-by-step traction to form a geogrid network;

[0071] h, Meter counting and winding.

[0072]

specific Embodiment approach 3

[0074] A method for producing a glass-plastic composite geogrid, comprising the following steps:

[0075] a. Mix raw materials: high-density polyethylene and additives, the ratio is 8% carbon black, 3% defoamer;

[0076] b. Pass the raw materials through the extruder, the temperature of the extruder is 200°C; the glass fiber yarn is mixed by guiding co-extrusion coating, and the temperature of the co-extrusion coating mixing head is 215 °C;

[0077] c. Form a strip blank through a mold, and the mold temperature is 215°C;

[0078] d. Stretch the strip blank at 75°C; the stretching ratio is 8 times;

[0079] e. Knurling process, knurling temperature 65°C

[0080] f, counting meters into a plate;

[0081] g. Horizontal strips and longitudinal strips are fixed step-by-step traction to form a geogrid network;

[0082] h, Meter counting and winding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com