Drilling equipment for columnar pieces

A technology for drilling equipment and columnar parts, which is applied in drilling/drilling equipment, boring/drilling, metal processing equipment, etc. It can solve the problems of low manual operation efficiency, difficult to grasp drilling accuracy, and high material scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

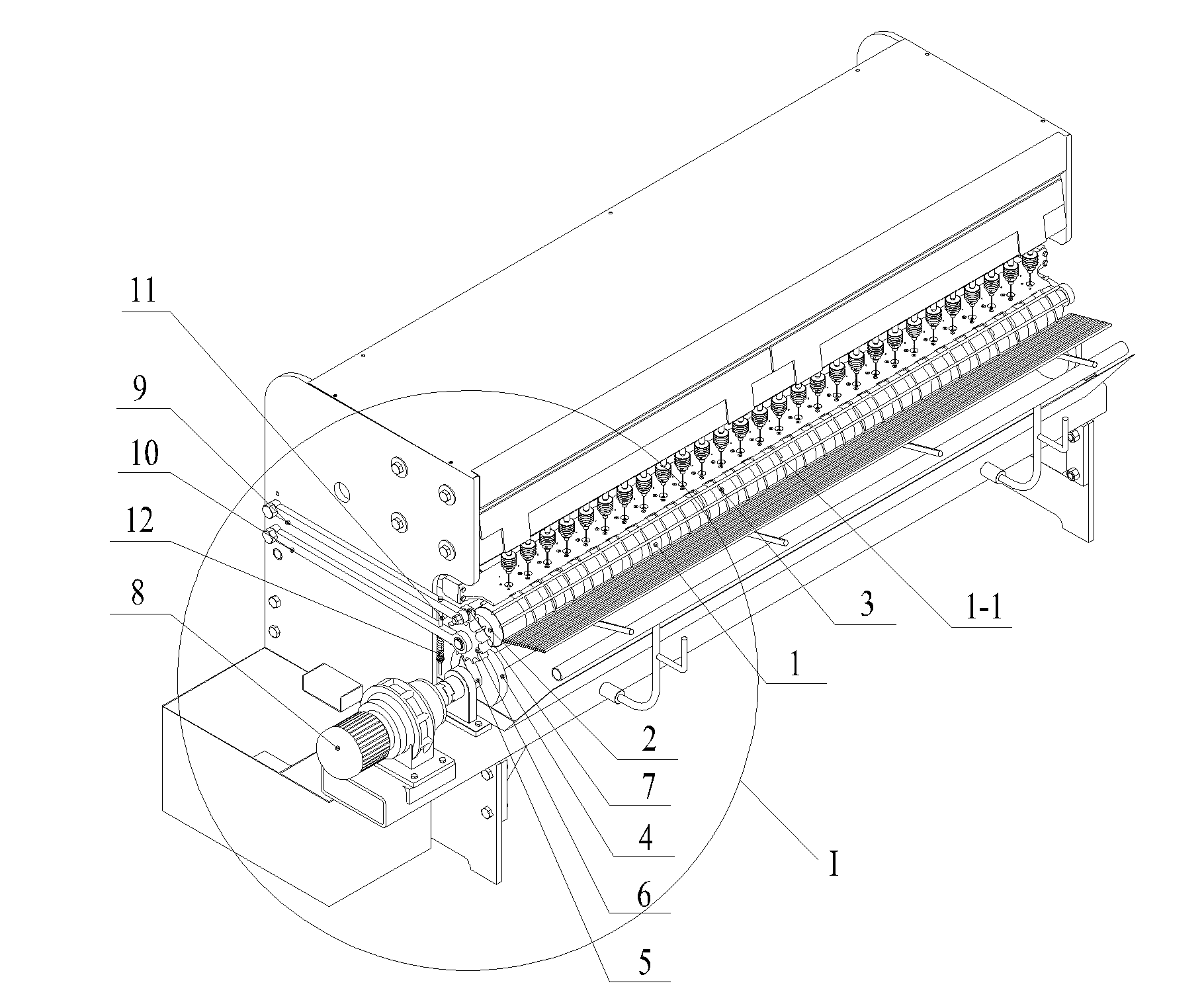

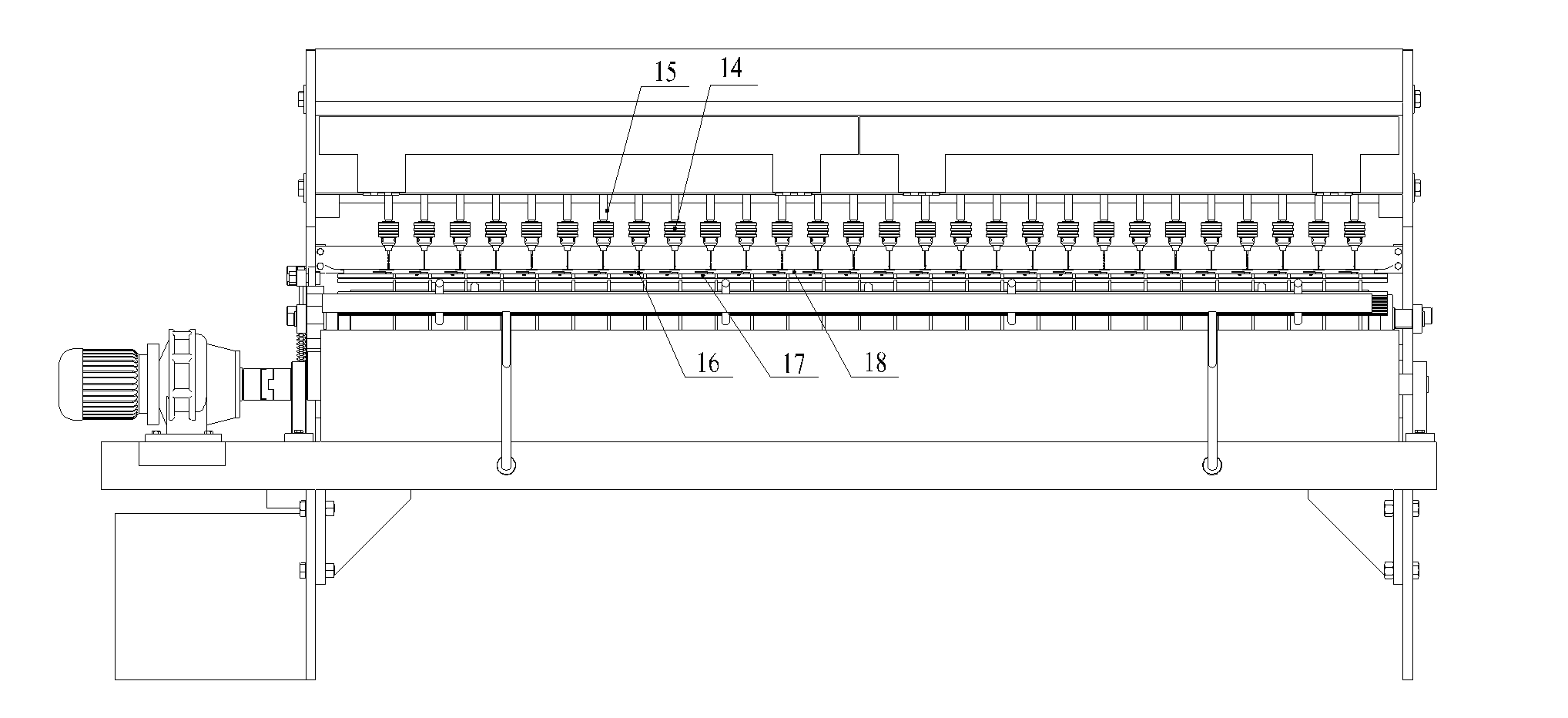

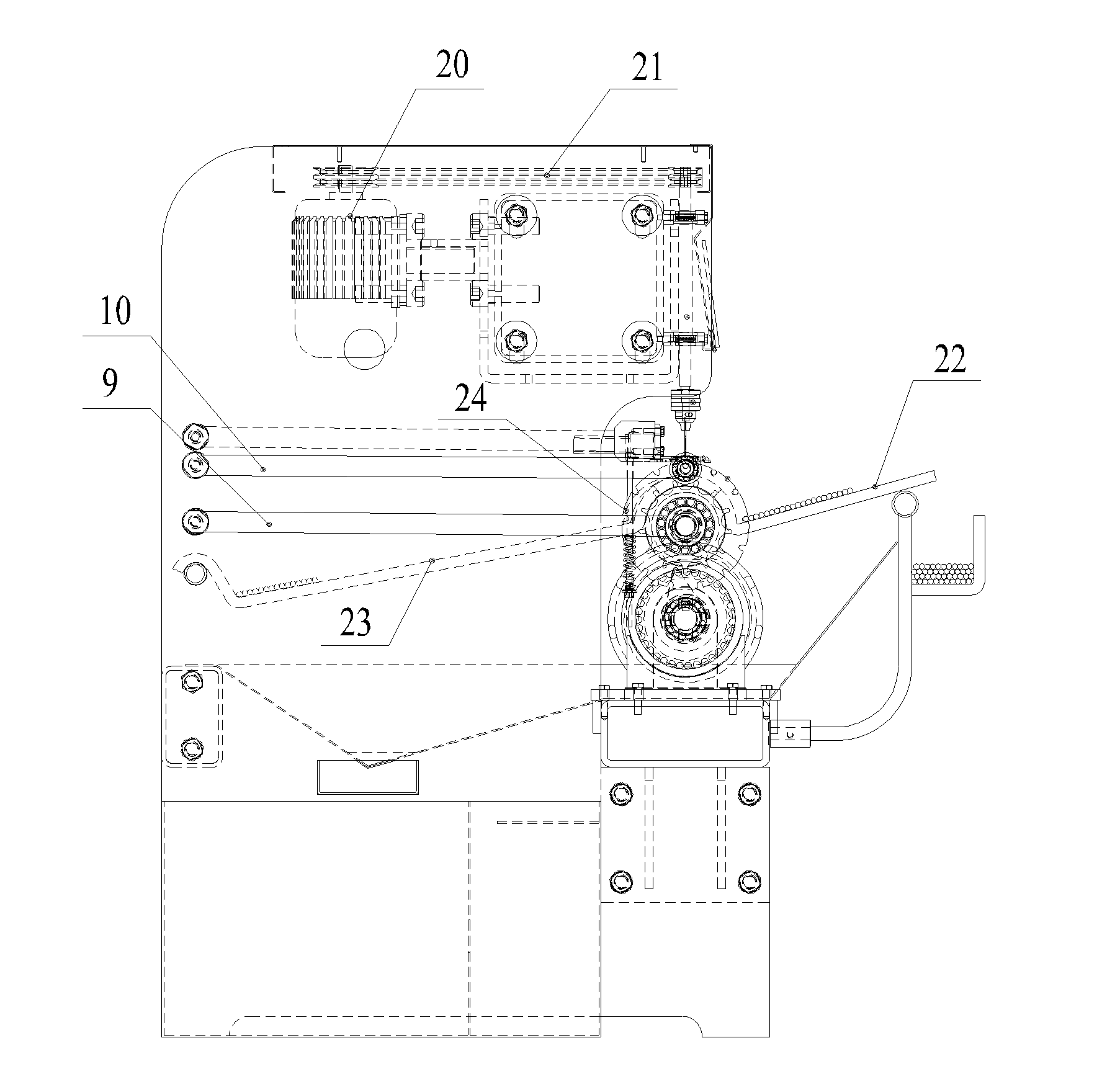

[0030] Please see Figure 1-Figure 3 , figure 1 It is a three-dimensional structural schematic diagram of a specific embodiment of the columnar member drilling equipment provided by the present invention; figure 2 for figure 1 Schematic diagram of the front view structure of the middle column drilling equipment; image 3 for figure 1 Schematic diagram of the left view structure of the middle column drilling equipment.

[0031] Such as Figure 1-Figure 3 As shown, the column drilling equipment provided by the present invention includes a feed shaft 1 and a plurality of drill bits 13; a plurality of drill bits 13 are fixedly arranged side by side in the vertical direction, and the feed shaft 1 is arranged on the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com