Ultraprecise turning method of optical lens with incline

A processing method and technology of optical mirror, applied in the field of optical device manufacturing and ultra-precision machining, can solve the problems of tool destructive influence, insufficient tool acceleration, tool cutting interference, etc., to improve processing efficiency, reduce tool clearance angle, increase large size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

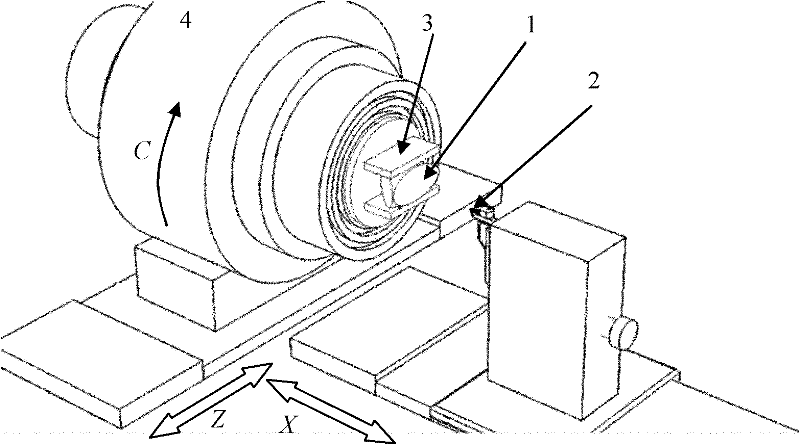

[0021] figure 1 It is a processing schematic diagram of the present invention. In the figure, after the large-slope optical mirror 1 is rough-machined, the slope to be processed is firstly processed into an initial plane, and fixed on an ultra-precision lathe with a fixture 3 . The ultra-precision lathe is a three-axis machining system. The machine tool coordinate system is defined as the Z-axis in the cutting depth direction of the tool, the X-axis in the horizontal feed direction of the tool, and the C-axis in the rotation direction of the spindle 4. In addition, for the convenience of later calculations, the direction perpendicular to the X-axis and Z-axis is defined as the Y-axis direction, and there is no motion axis in this direction. During processing, it is necessary to adjust the initial plane of the processing slope to be perpendicular to the Z axis. The diamond tool 2 processes and shapes the free-form surface of the inclined plane under the coordinated motion of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com