Lithium ion battery system for hybrid electric vehicle (HEV)

A hybrid electric vehicle and lithium-ion battery technology, applied in the field of heat dissipation system design, can solve the problems of narrow adaptable temperature range, few applications, high cost, etc., to overcome the large space of serial heat dissipation mode and parallel heat dissipation structure, and ensure temperature uniformity , The effect of simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

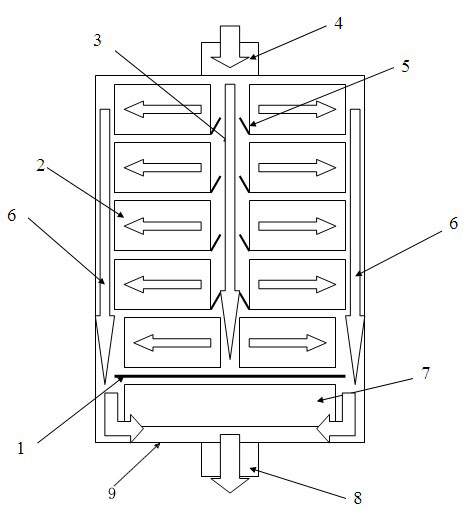

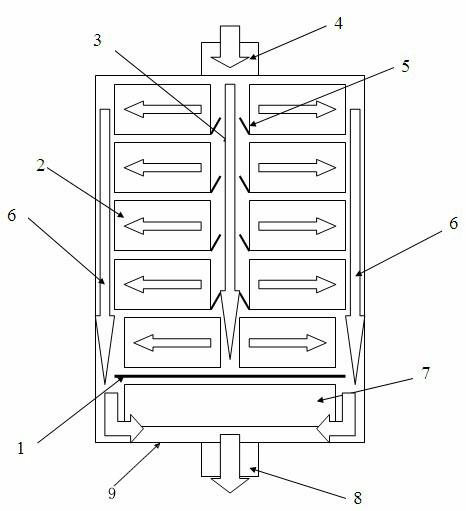

[0012] The lithium-ion battery system proposed by the present invention can be used for plug-in hybrid vehicles, see figure 1 , which includes: 1. windshield; 2. battery module group; 3. air inlet wedge-shaped channel; 4. battery box air inlet; 5. diversion grille; 6. air outlet channel; 7. battery management System and high voltage device part; 8. Battery box air outlet; 9 Battery box. The battery box 9 is fixed under the chassis of the vehicle by bolts. The battery box air inlet 4 is designed at one end of the battery box near the front cabin of the vehicle, and the battery box air outlet 8 is designed at the other end of the battery box near the trunk. A total of 10 groups of battery module groups 2 are symmetrically arranged in two rows in a single layer and arranged in the battery box 9, and a wedge-shaped air inlet channel 3 is formed between the two rows, which is formed by reducing the gap between the symmetrical arrangement of the batteries on both sides. The inner d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com