Water swellable rubber and production method thereof

A technology of water-swellable rubber and production method, applied in the field of water-swellable rubber, can solve the problems of backward processing technology, low work efficiency and low output, and achieve the effects of fewer processing steps, high work efficiency and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0033] Embodiment 1~6 encounters water-swellable rubber

[0034] Table 1 shows the formulations of water-swellable rubber examples 1-6, and the unit is mass percent.

[0035] Table 1 water-swellable rubber embodiment 1~6

[0036] Example

serial number

glue

water soluble poly

pottery

earth

Dihydroxypoly

Accelerator

TT

2-Mercaptobenzene

change

oxidation

1

32.9

42.8

8.2

3.0

1.0

3.9

3.9

1.0

2.3

1.0

2

40.2

40.4

8.0

2.4

0.4

2.8

3.2

0.8

1.2

0.6

[0037] 3

37.9

40.2

8.1

2.6

0.8

3.4

3.6

0.9

1.7

0.8

4

36.6

40.5

8.1

2.7

...

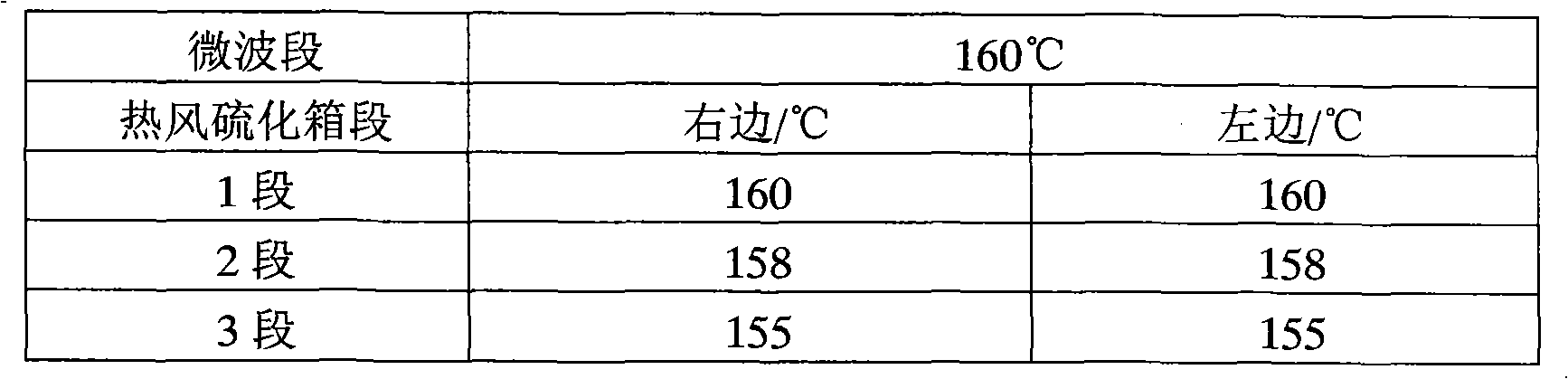

Embodiment 5

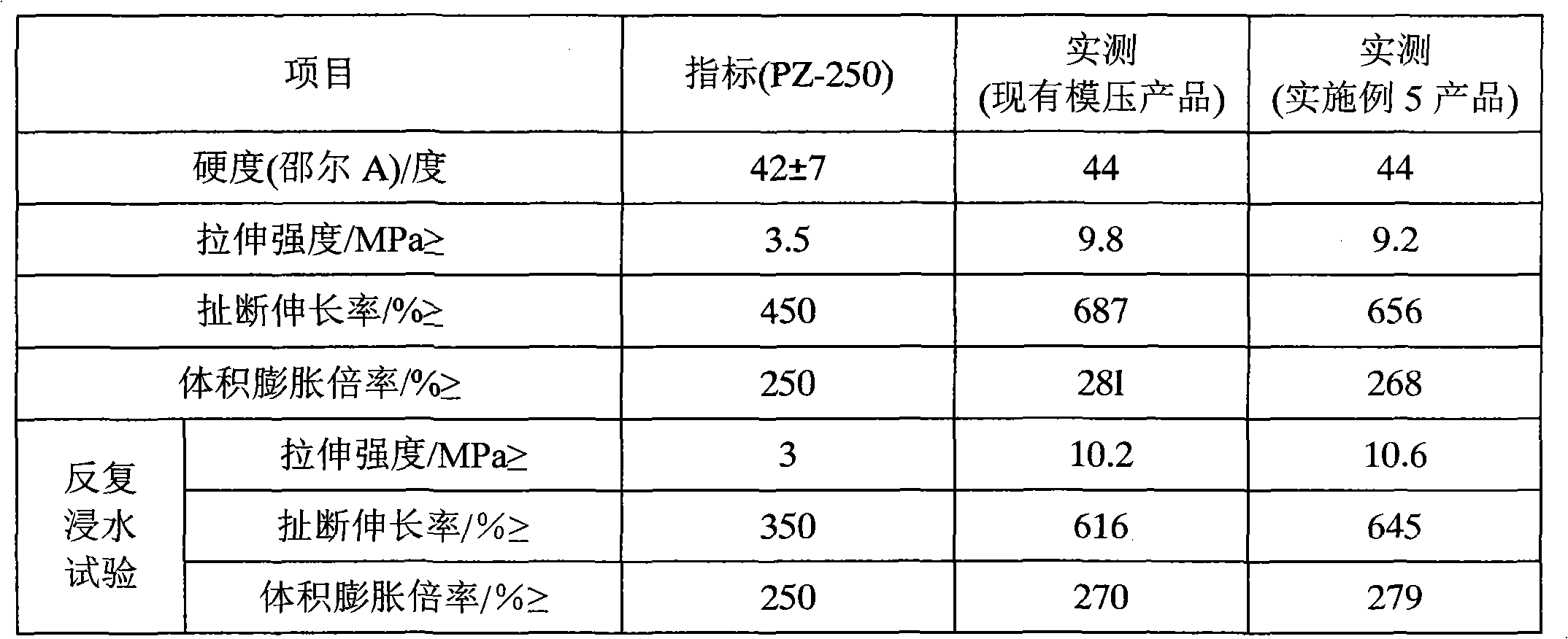

[0045] The product physical properties test result that embodiment 5 prepares is as shown in table 4:

[0046] Table 4

[0047]

[0048] Implementation of the standard {GB / T18173.3-2002} polymer waterproof material part 3 water-swellable rubber.

[0049] The data in Table 4 shows that the performance of the water-swellable rubber using the continuous extrusion microwave vulcanization process in the present invention fully complies with the national standard technical indicators and meets the use requirements, and some properties are better than the existing molding method.

[0050] Table 5 shows the output comparison between the production process of the present invention and the existing process when producing the same water-swellable rubber.

[0051] table 5

[0052]

Processing technology

Flat vulcanization

(20 holes)

Extrusion Microwave Vulcanization

(single mouth type)

yield increase

Output (m / 8 hours)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com