Method for preparing manganese dioxide nano rod at low temperature

A technology of manganese dioxide and nanorods, applied in the direction of manganese oxide/manganese hydroxide, nanotechnology, etc., can solve the problems of complex process, high temperature, high cost, etc., and achieve the effect of high purity, low cost, simple process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

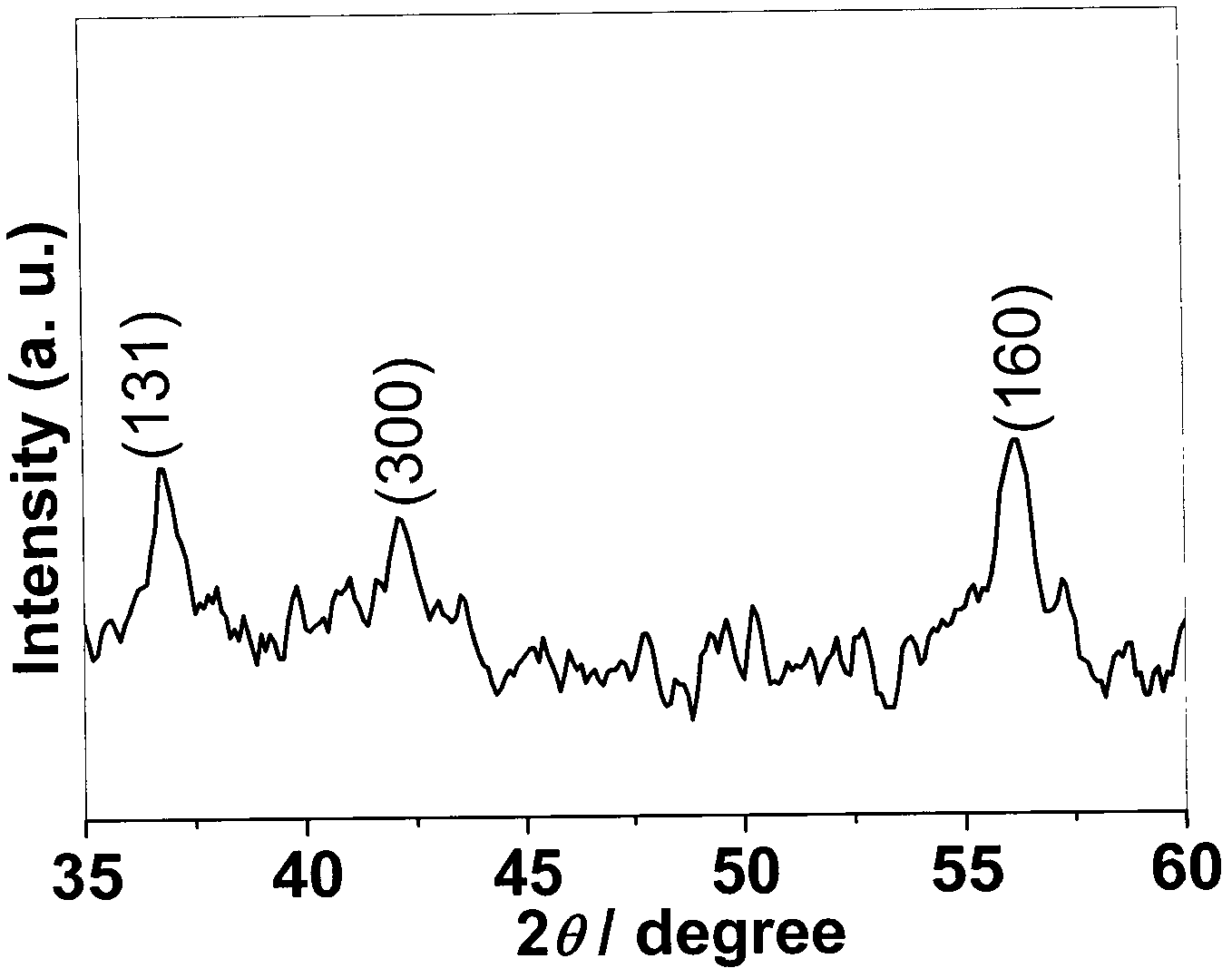

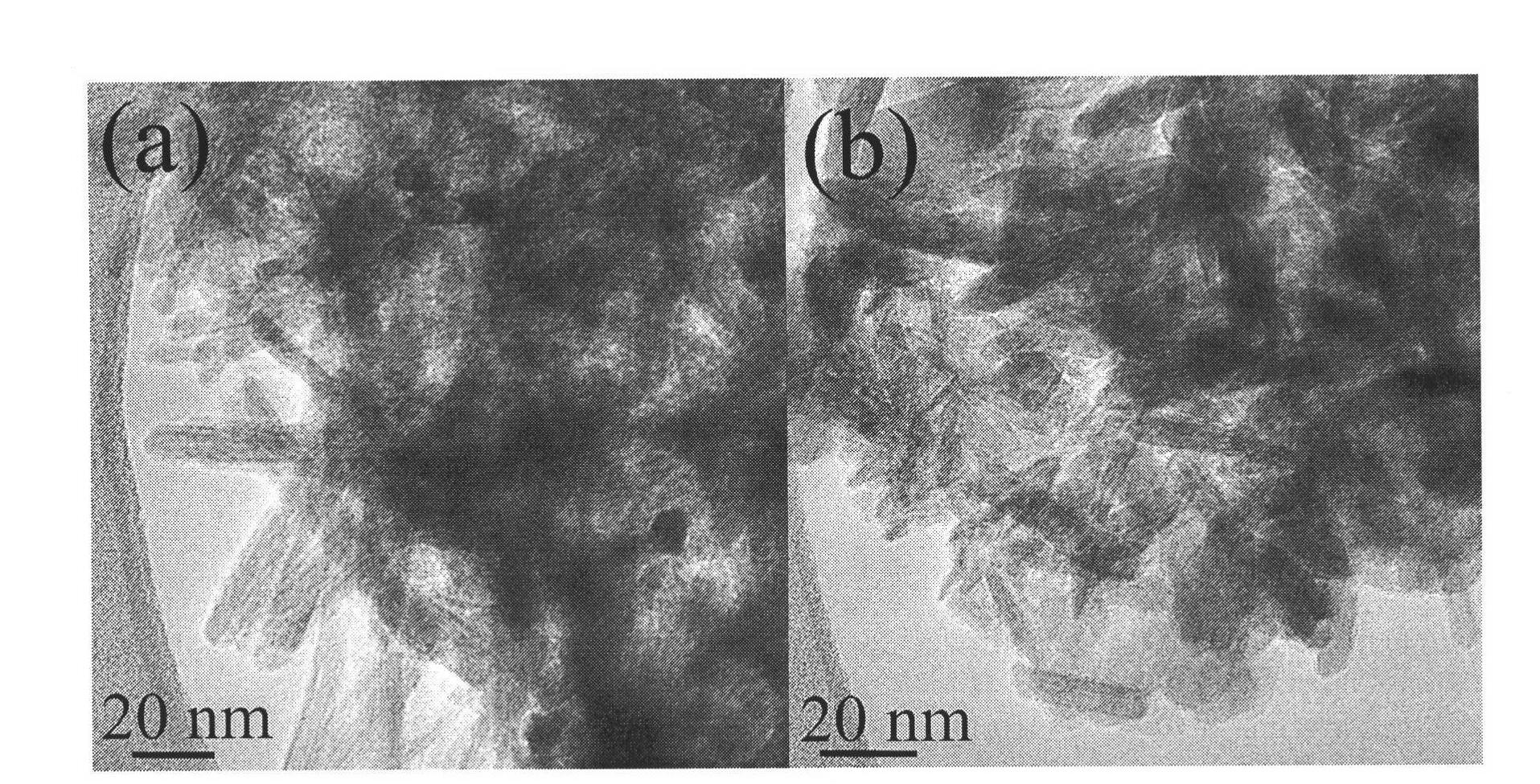

[0018] 0.06 moles of manganese chloride tetrahydrate (MnCl 2 4H 2 O), 0.03 mol potassium permanganate (KMnO 4 ) after mixing evenly, then dissolved in 200 ml of distilled water. During the dissolution process, continuous stirring is required to accelerate the dissolution rate of the reactants. After the reactants were completely dissolved in water, 100 ml of 1M HCl solution was slowly added under continuous stirring to accelerate the reaction rate of the reactants. Finally, the mixed solution was placed in a constant temperature water bath at 60° C., kept warm for 36 hours, and then cooled to room temperature. The precipitate was washed by centrifugation with deionized water several times until the pH value was neutral, and dried at room temperature to obtain a black powdery product. The XRD diffraction pattern of sample ( figure 1 shown) confirmed that the product is orthorhombic γ-MnO 2 , the resulting XRD pattern is consistent with that of the reference MnO 2 The sta...

Embodiment 2

[0020] 0.06 moles of manganese chloride tetrahydrate (MnCl 2 4H 2 O), 0.02 mol potassium permanganate (KMnO 4 ) after mixing evenly, then dissolved in 200 ml of distilled water. During the dissolution process, continuous stirring is required to accelerate the dissolution rate of the reactants. After the reactants were completely dissolved in water, 100 ml of 1M HCl solution was slowly added under continuous stirring to accelerate the reaction rate of the reactants. Finally, the mixed solution was placed in a constant temperature water bath at 80° C., kept warm for 24 hours, and then cooled to room temperature. The precipitate was washed by centrifugation with deionized water several times until the pH value was neutral, and dried at room temperature to obtain a black powdery product. The appearance of product, structure etc. are all similar to embodiment 1.

Embodiment 3

[0022] 0.06 moles of manganese chloride tetrahydrate (MnCl 2 4H 2 O), 0.015 mol potassium permanganate (KMnO 4 ) after mixing evenly, then dissolved in 200 ml of distilled water. During the dissolution process, continuous stirring is required to accelerate the dissolution rate of the reactants. After the reactants were completely dissolved in water, 100 ml of 1M HCl solution was slowly added under continuous stirring to accelerate the reaction rate of the reactants. Finally, the mixed solution was placed in a constant temperature water bath at 70° C., kept warm for 36 hours, and then cooled to room temperature. The precipitate was washed by centrifugation with deionized water several times until the pH value was neutral, and dried at room temperature to obtain a black powdery product. The appearance of product, structure etc. are all similar to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com