Multifunctional high-property wear resistant conveyer belt

A high wear-resistant, conveyor belt technology, used in the field of conveyor belts, can solve the problems of shortened service life of conveyor belts, production interruptions, poor wear resistance of covering layers, etc., to improve production efficiency, long service life, and good wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

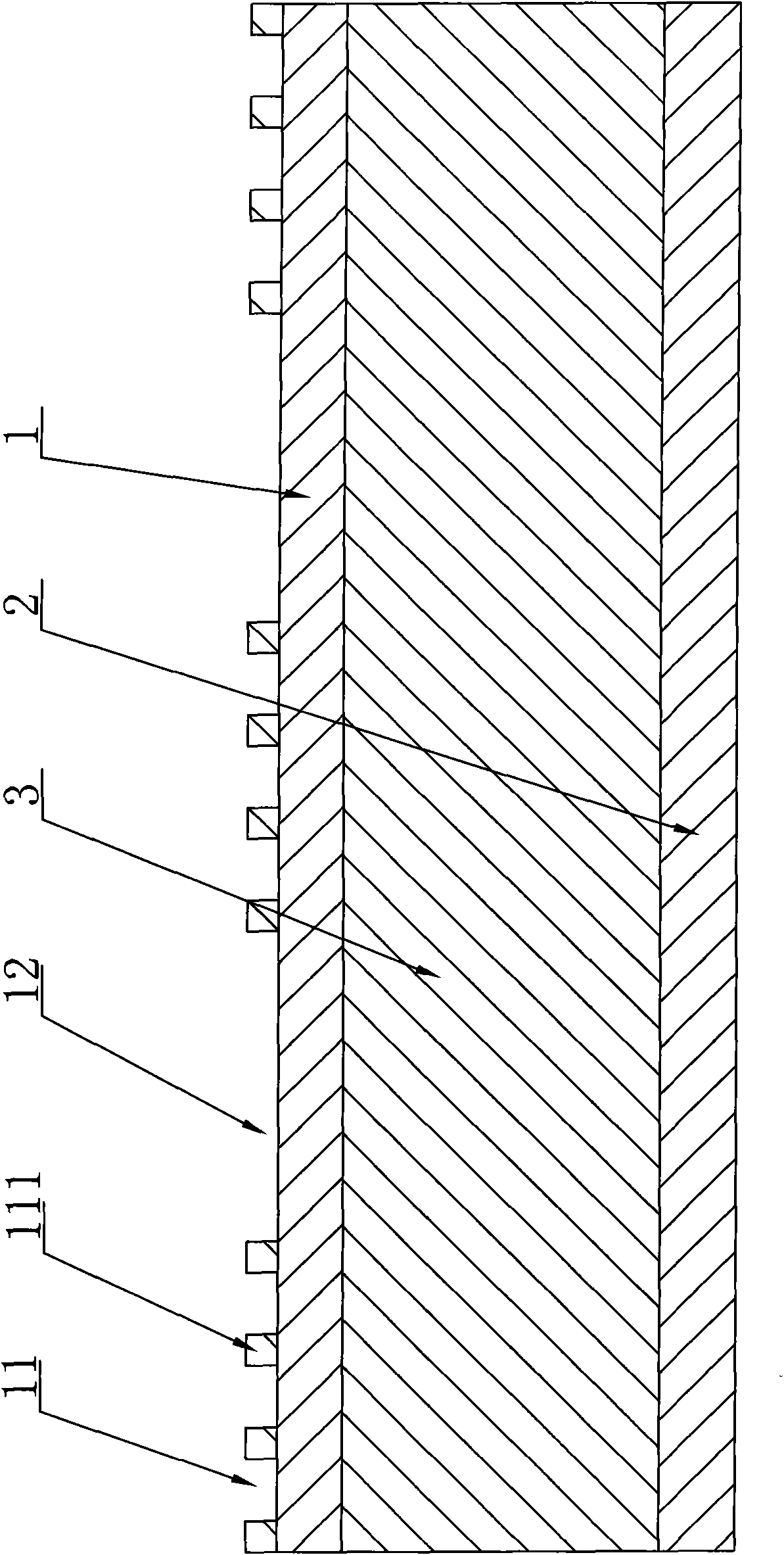

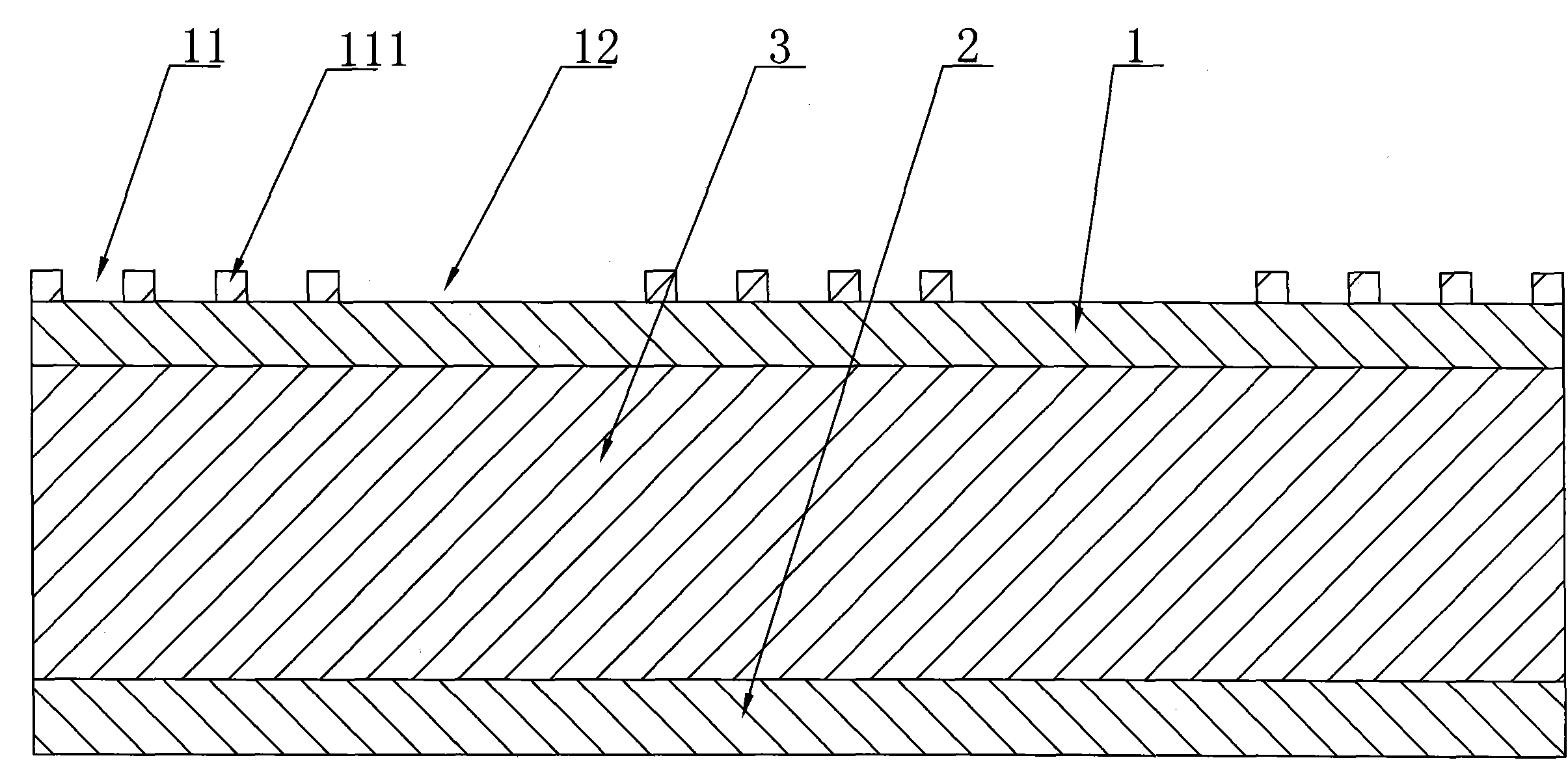

[0008] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0009] like figure 1 As shown, the multifunctional high wear-resistant conveyor belt includes: an upper wear-resistant layer 1 and a lower wear-resistant layer 2 made of high-performance wear-resistant materials, and a The canvas core layer 3 is uniformly provided with anti-skid sections 11 on the upper wear-resistant layer 1, and smooth sections 12 are arranged between adjacent anti-skid sections 11. The anti-skid section 11 is composed of several Consists of bumps 111 on the top, and bumps 111 are made of high-performance wear-resistant materials.

[0010] The multi-functional high wear-resistant conveyor belt with the above structure has good wear resistance and impact resistance. The conveyor belt is not easy to have holes during use, has a long service life, is more convenient to use, improves production efficien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com