Method for preparing mono-disperse microemulsion, liposome and microsphere based on microfluidic technology

A monodisperse, microfluidic chip technology, applied in biochemical equipment and methods, liposome delivery, emulsion delivery, etc., can solve the problems of ununiform size, poor repeatability, and low target encapsulation rate. Good repeatability and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

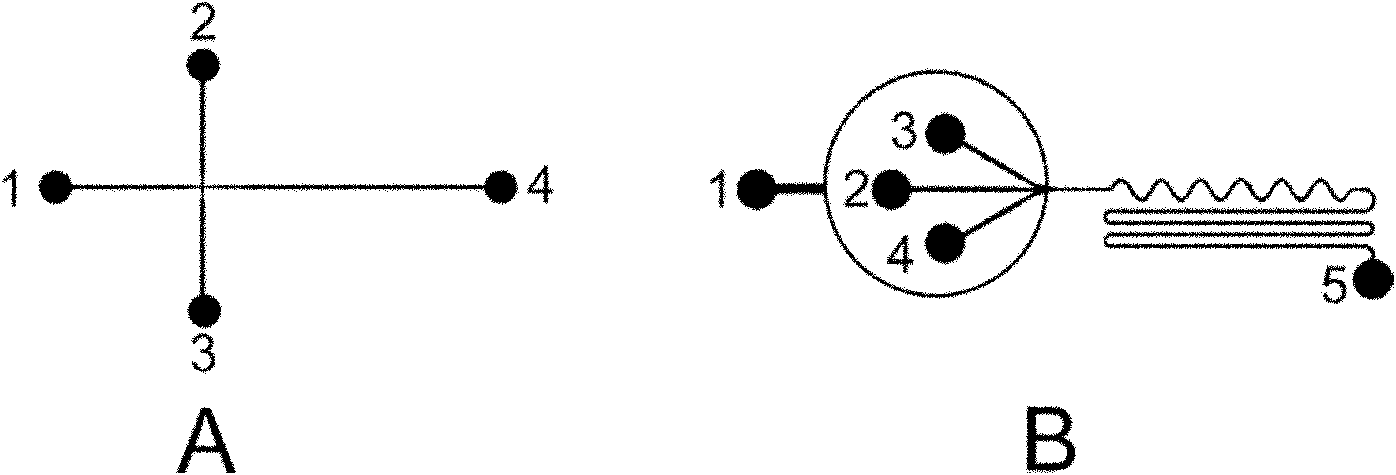

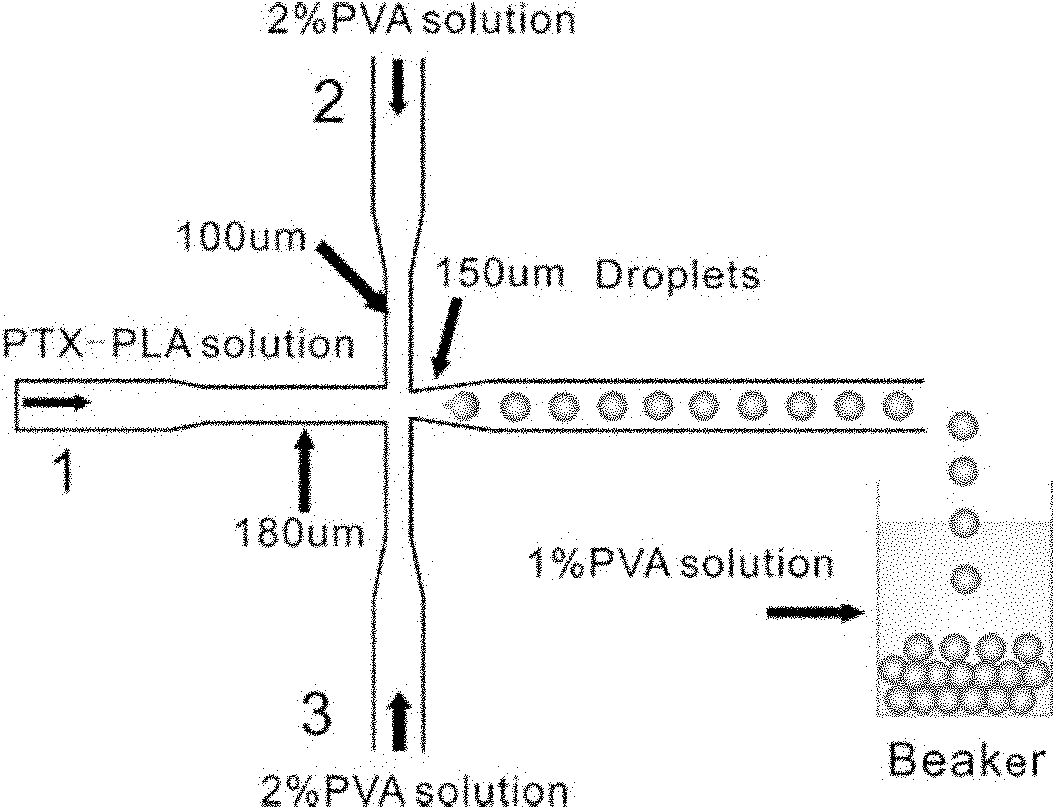

[0042] (2) Preparation of dispersed phase and continuous phase: dissolve fat-soluble drug paclitaxel and polylactic acid in chloroform (oil phase) as dispersed phase; dissolve polyvinyl alcohol or other water-soluble emulsifiers in water (water phase) as continuous phase; in figure 1 In the shown microfluidic chip device (the channel is modified by hydrophilicity), the dispersed phase is passed into channel 1 through the pump, the continuous phase is passed into channels 2 and 3, and the monodisperse O / W microemulsion ( or droplets); when water-soluble drugs are to be embedded, the water-soluble drug solution can be used as dispersed phase 1, and the chloroform solution of polylactic acid can be used as dispersed phase 2, and dispersed phase 1 can be cut into W / O microemulsion with dispersed phase 2, The continuous phase in which the hydrophilic emulsifier is dissolved is then sheared into the dispersed phase 2 again to form a W / O / W microemulsion.

[0043] (3) Preparation of ...

Embodiment 1

[0045] Embodiment 1, preparation polylactic acid microsphere

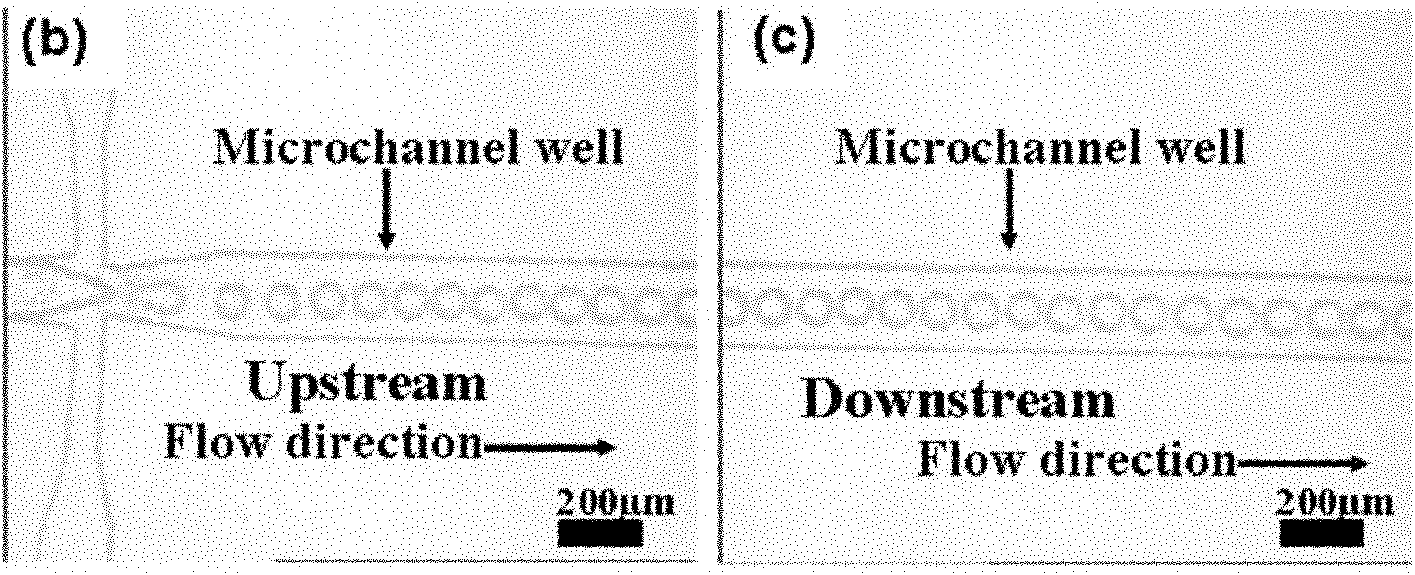

[0046] The microfluidic chip device as figure 1 As shown assembled. A chloroform solution of 30 mg / mL polylactic acid (molecular weight 10000) was prepared; a solution of PVA (model: average degree of polymerization 1750±50) with a mass concentration of 2% was prepared as the continuous phase. The dispersed phase and the continuous phase were transported to the microfluidic chip by a micropump (see figure 2 ), in the chip, through the shearing action of the continuous phase, the dispersed phase forms monodisperse droplets (see image 3 ); for the hydrophilicity characterization of chip channel modification, see Figure 4 .

[0047] The collected droplets are placed in a water bath at room temperature to remove the organic solvent, and the pelletized material is precipitated and solidified into microspheres; the solidified drug-loaded microspheres are filtered, washed with water, and vacuum-dried or freeze-drie...

Embodiment 2

[0048] Example 2, preparation of polylactic acid microspheres wrapped with paclitaxel

[0049] The microfluidic chip device as figure 1As shown assembled. Prepare a chloroform solution of 30 mg / mL polylactic acid (molecular weight 10000), weigh a certain amount of paclitaxel and dissolve it in the above solution, and prepare solutions containing paclitaxel 1 mg / mL and 2 mg / mL respectively as the dispersed phase; prepare a mass concentration of 2 % PVA solution as the continuous phase. The dispersed phase and the continuous phase are transported to the microfluidic chip by a micropump to form monodisperse droplets; the collected droplets are placed in a 40°C water bath to remove the organic solvent; the solidified drug-loaded microspheres are filtered and washed with water , vacuum-dried or freeze-dried at room temperature.

[0050] attached Figure 6 (a-b) are the optical micrographs of the prepared drug-loaded polylactic acid microspheres with different particle sizes, fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com