Thermochromic microparticles, dispersions thereof, and manufacturing method thereof, as well as light-modulating coatings, light-modulating films and light-modulating inks

A manufacturing method and technology for microparticles, which can be used in color-changing fluorescent materials, heat-sensitive coatings, chemical instruments and methods, etc., and can solve the problems of poor dimming, particle agglomeration, and difficulty in obtaining sub-micron microparticles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

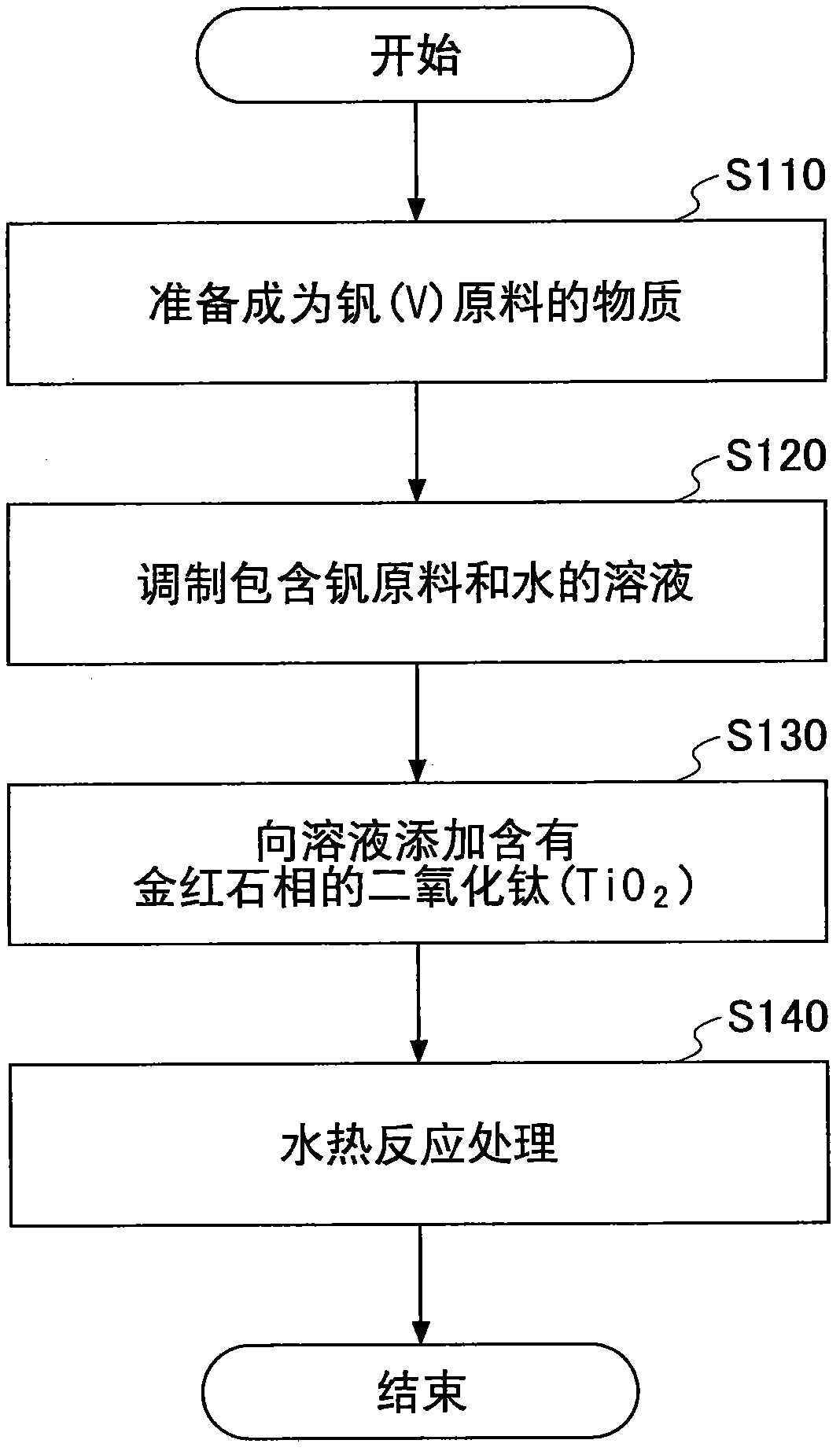

Method used

Image

Examples

Embodiment 1

[0111] First, vanadium pentoxide (V 2 o 5 , Wako special grade), oxalic acid dihydrate ((COOH) 2 2H 2 O, Wako Chemical Special Grade) and 200ml of pure water, and prepare an aqueous solution by stirring. Furthermore, 1.5 ml of sulfuric acid was added to this aqueous solution for pH adjustment.

[0112] Next, commercially available titanium dioxide (TiO 2 ) powder (a purity of 99% or more, an average particle size of 100nm or less, and a rutile ratio of 40% or more), the titanium dioxide (TiO 2 ) powder relative to V 2 o 5 The weight ratio is 50%, thus obtaining a cloudy liquid.

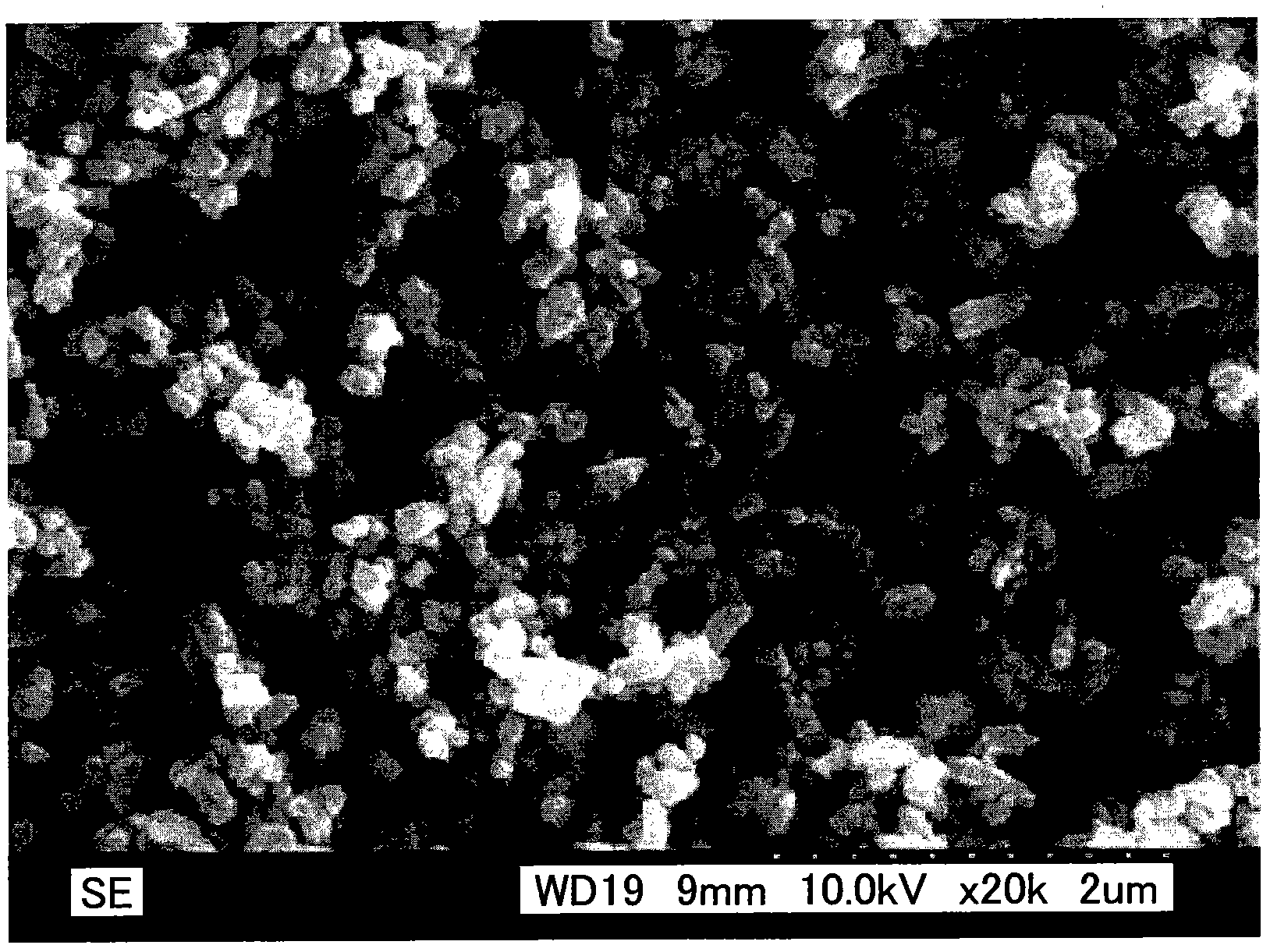

[0113] Next, the turbid liquid is sealed in a commercially available pressure cooker for hydrothermal reaction (Hu-25 type manufactured by Sanai Scientific Co., Ltd.) (Teflon (registered trademark) inner cylinder with a volume of 25 ml in the SUS body), and the pressure cooker is heated at 220 ℃ for 24 hours to carry out hydrothermal reaction. Accordingly, fine particles in a monodisperse sta...

Embodiment 2

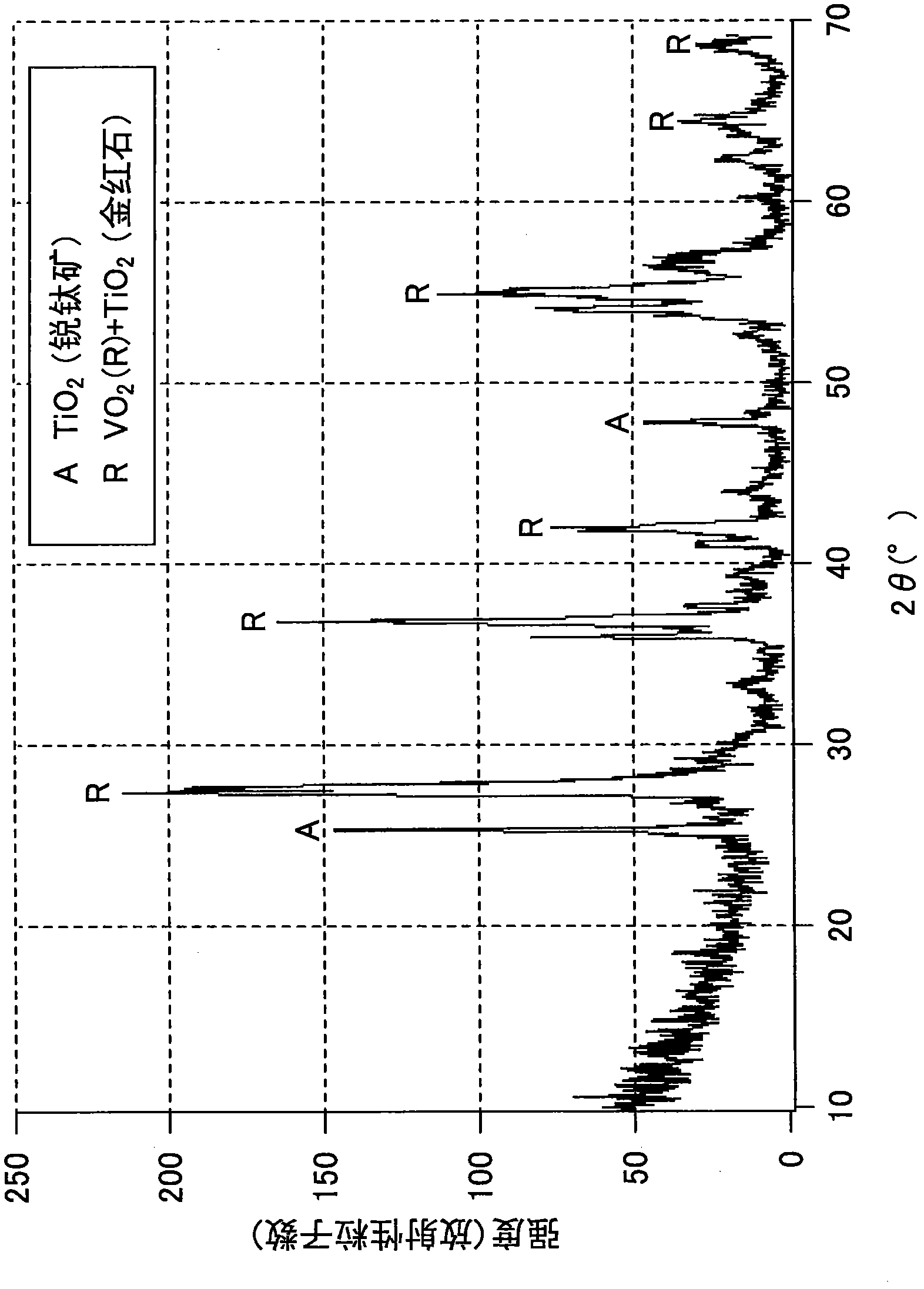

[0123] In Example 2, rutile-type titanium dioxide prepared in a laboratory was used as a seed crystal.

[0124] First, at room temperature, 10ml of titanium tetrachloride (TiCl 4 ) aqueous solution (Ti concentration 16.5% by weight) was dropped into 30 ml of pure water while stirring to prepare a diluted solution of titanium chloride. The diluted solution was poured into a glass beaker, covered and placed in a constant temperature dryer, and kept at 55° C. for 6 hours. The resulting product was filtered, washed repeatedly with pure water, and then dried. Through this step, white titanium oxide powder was obtained. As a result of XRD measurement, it was confirmed that the obtained powder was rutile titanium dioxide (TiO 2 ).

[0125] Secondly, in addition to the rutile titanium dioxide (TiO 2 ) powder as a seed crystal, the fine particles of Example 2 were obtained by the same procedure as in Example 1.

[0126] Figure 6 The XRD measurement results of the obtained fine ...

Embodiment 3

[0128] The fine particles of Example 3 were prepared in the same procedure as in Example 1 above. However, in this example, ammonium tungstate p-pentahydrate (Wako Pure Chemicals, composed of about (NH 4 )10W 12 o 41 ·5H2 O) so that the W:V atomic ratio is 1.0%.

[0129] Figure 8 shows the measurement results of the optical transmission characteristics of the dimming glass substrate samples at 10°C and 80°C. Also in this sample, it was confirmed that the transmittance changes with temperature. Figure 9 The results of the temperature dependence of the infrared transmittance at a wavelength of 2000 nm measured using this sample are shown in . From this figure, it is clear that the transmittance changes rapidly as the temperature rises. It should be noted that, in this example, the transition temperature is about 41°C. It was confirmed that the transition temperature can be lowered by adding tungsten.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com