Cellulosic and lignocellulosic structural materials and methods and systems for manufacturing such materials

A technology of lignocellulose and cellulose, applied in the system field of materials, can solve problems such as incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

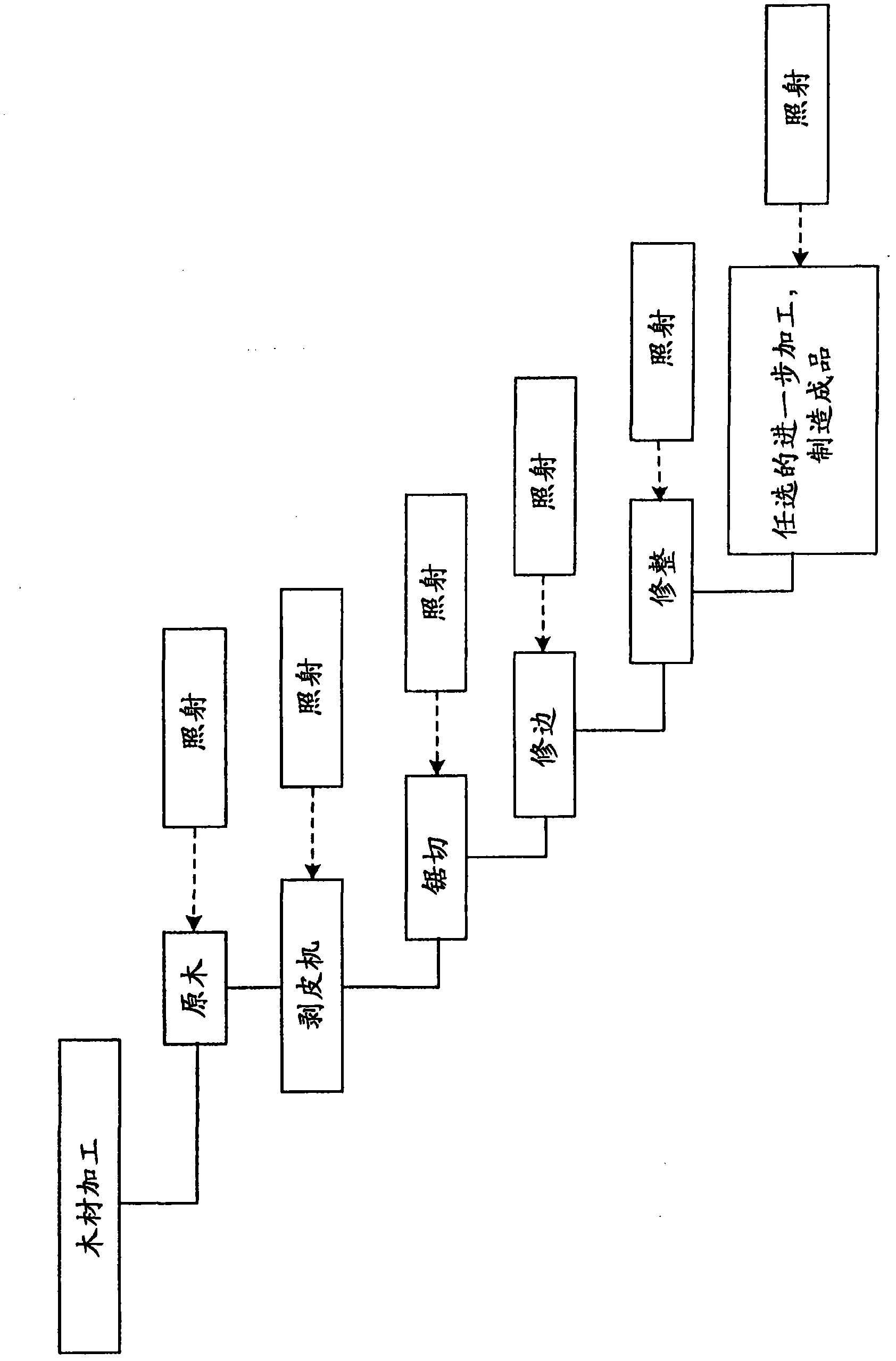

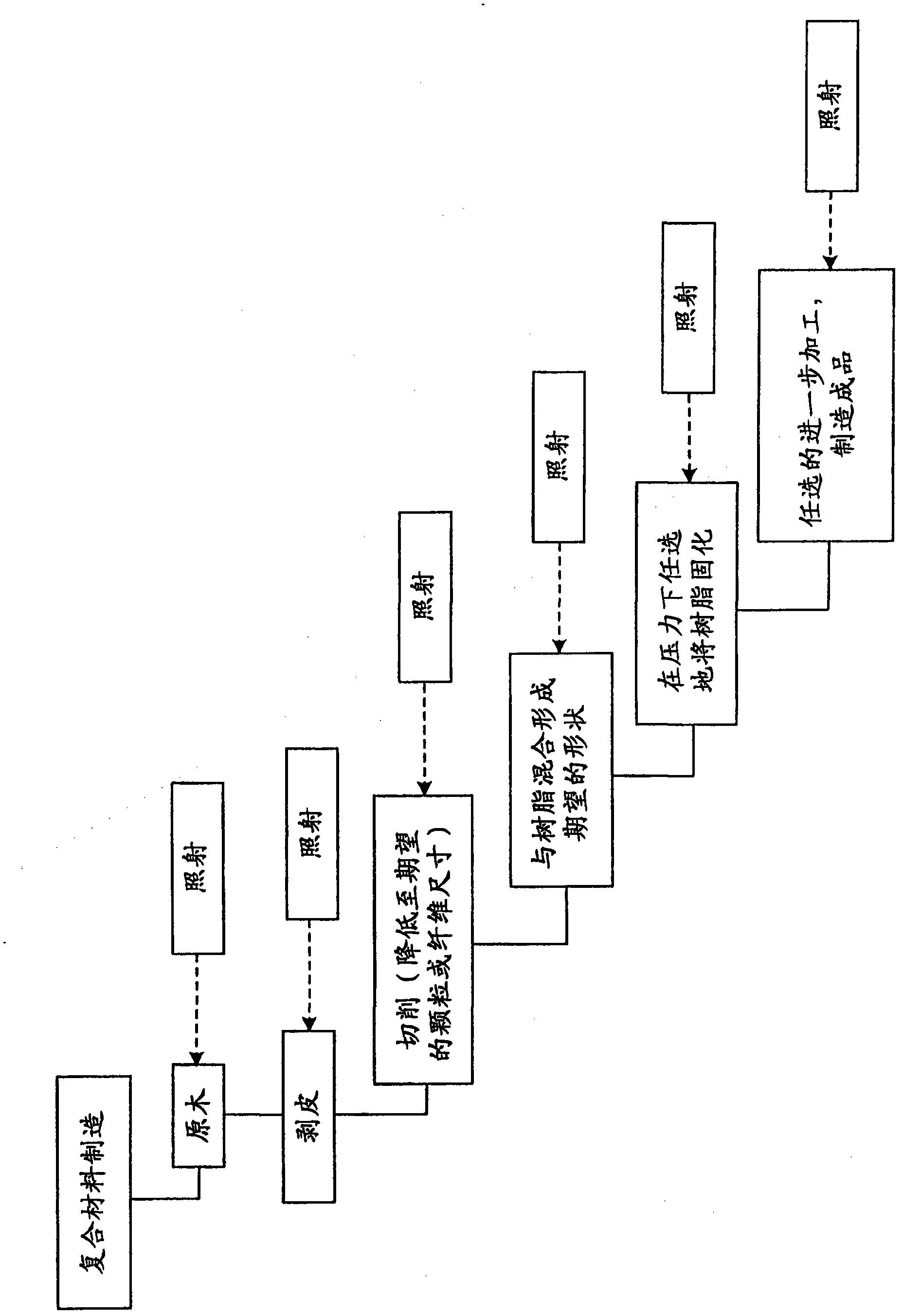

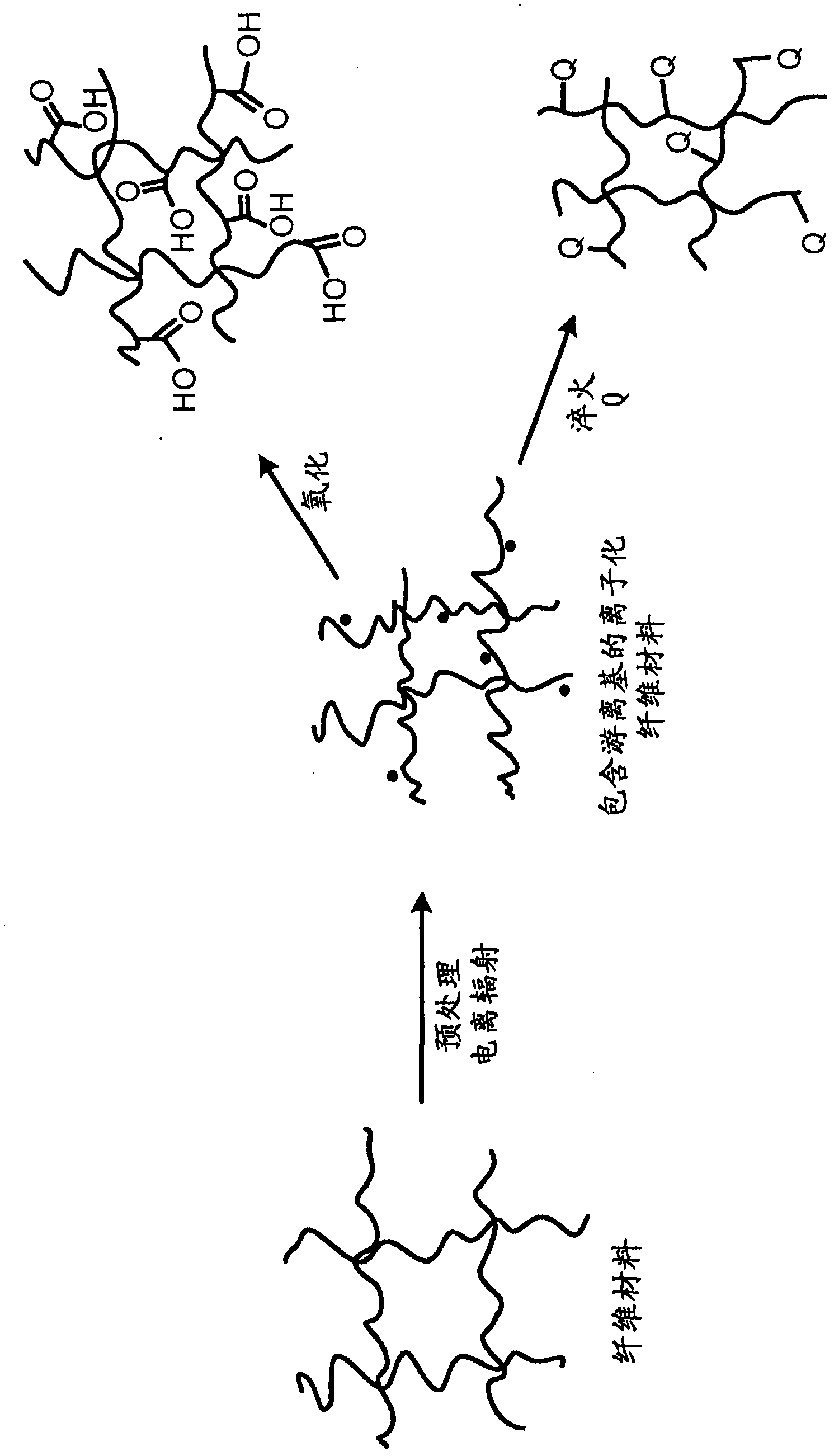

Method used

Image

Examples

Embodiment 1

[0209] Example 1-Method for determining the molecular weight of cellulose and lignocellulosic materials by gel permeation chromatography

[0210] This example illustrates how to determine the molecular weight of the materials discussed herein. The cellulosic and lignocellulosic materials used for analysis are processed as follows:

[0211] Get a 1500 lb pallet (skid) from International Paper with 30lb / ft 3 The original bleached white kraft cardboard of the bulk density. Fold the material flat and add it to a 3hp Flinch Baugh shredder at a rate of about 15 to 20 pounds per hour. The shredder is equipped with two 12-inch rotating blades, two fixed blades and a 0.30-inch discharge creen. Adjust the gap between the rotating blade and the fixed blade to 0.10 inches. The output from the paper shredder is similar to the shredded flower (as above). The material similar to shredded flowers is added to the SC30 Munson rotary knife cutting machine. The discharge screen has 1 / 8 inch holes...

Embodiment 2

[0234] Example 2-Radiation treatment of boxwood samples

[0235] The 1 / 8 inch thick boxwood board is treated with electron beam radiation (5MeV electron beam) at a dose of 1MRad to 100MRad. The number after “B” in the table below indicates the received dose (for example, B means no exposure Wood plank, B1 means plank that received 1MRad, and B10 means plank that received 10MRad). Then ASTM D 790 and D 143 were used to test the bending strength of the wood board (crosshead speed of 0.1 inch / min and span / thickness of 14:1), and ASTM D 638 to test the tensile strength (using type I specimens and 0.2 inch / Minute crosshead speed). The results of this test are shown in Tables I and II below.

[0236] Table I Summary of test results-bending strength

[0237] Sample identification

average

Bending strength (psi) single value

B

11600

10800,11900,10800,12000,12600

B1

13300

13600,12700,13800,13300

B3

20200

21400,20000,18700,20700

B5

16500

16100,15600,16700,17600

B7

...

Embodiment 3

[0240] Example 3-Preparation of sheared fibrous material from bleached kraft paperboard

[0241] A 1500 lb pallet obtained from International Paper has 30lb / ft 3 The original bleached white kraft cardboard of the bulk density. Fold the material flat and add it to a 3hp Flinch Baugh shredder at a rate of about 15 to 20 pounds per hour. The shredder is equipped with two 12-inch rotating blades, two fixed blades and a 0.30-inch discharge screen. Adjust the gap between the rotating blade and the fixed blade to 0.10 inches. The output from the shredder is similar to shredded paper. The material similar to shredded flowers is added to the SC30 Munson rotary knife cutting machine. The discharge screen has 1 / 8 inch holes. The gap between the rotating blade and the fixed blade is set to about 0.020 inches. The rotary knife cutting machine cuts the paper pieces that pass through the blade, which resemble shredded paper flowers. The material obtained from the first shear was recharged...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com