Composite material bipolar plate for proton exchange membrane fuel cell and manufacturing method thereof

A technology of proton exchange membrane and composite materials, which is applied in the field of composite material bipolar plates and its production, can solve the problems that the electrical conductivity affects the output power of the battery stack, difficulty in mass industrial production, and unsatisfactory electrical conductivity, etc., so that the raw materials are easy to obtain , low cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

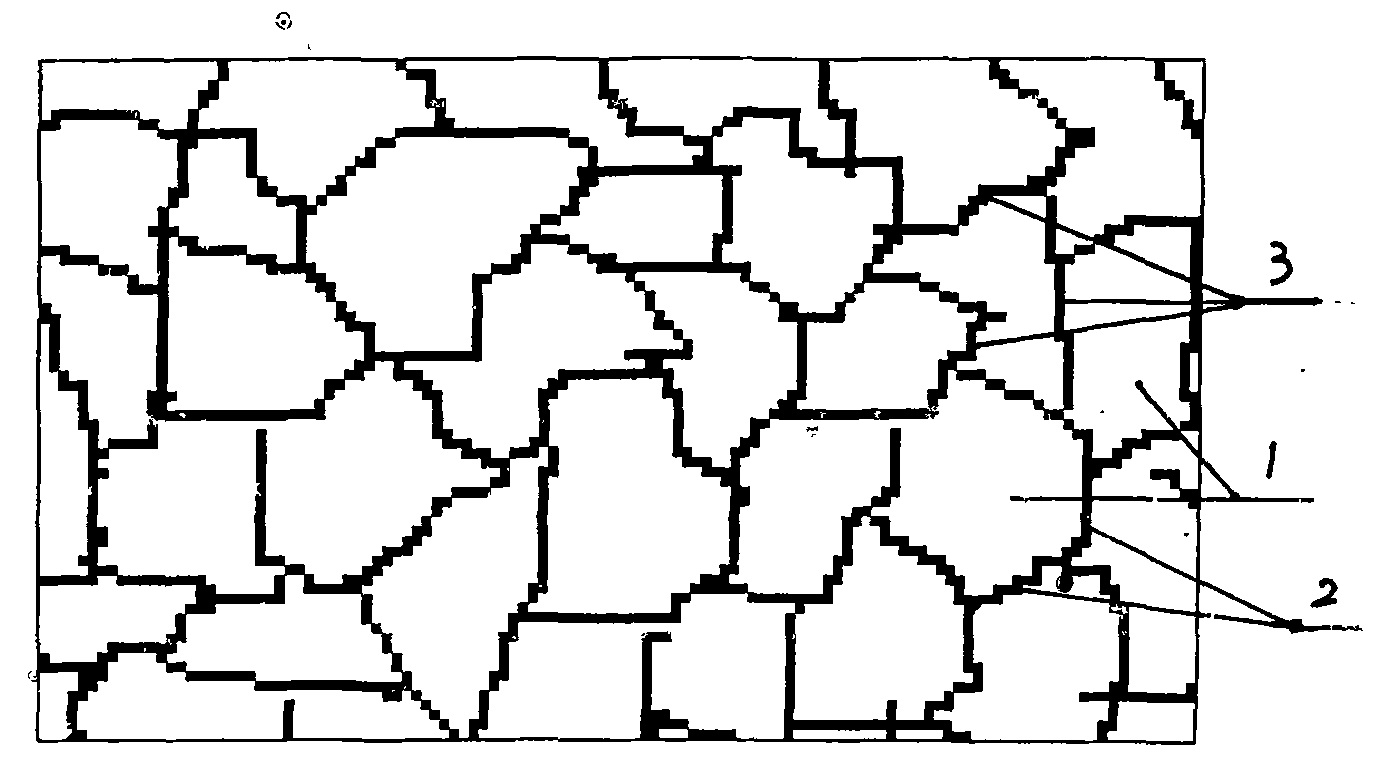

Image

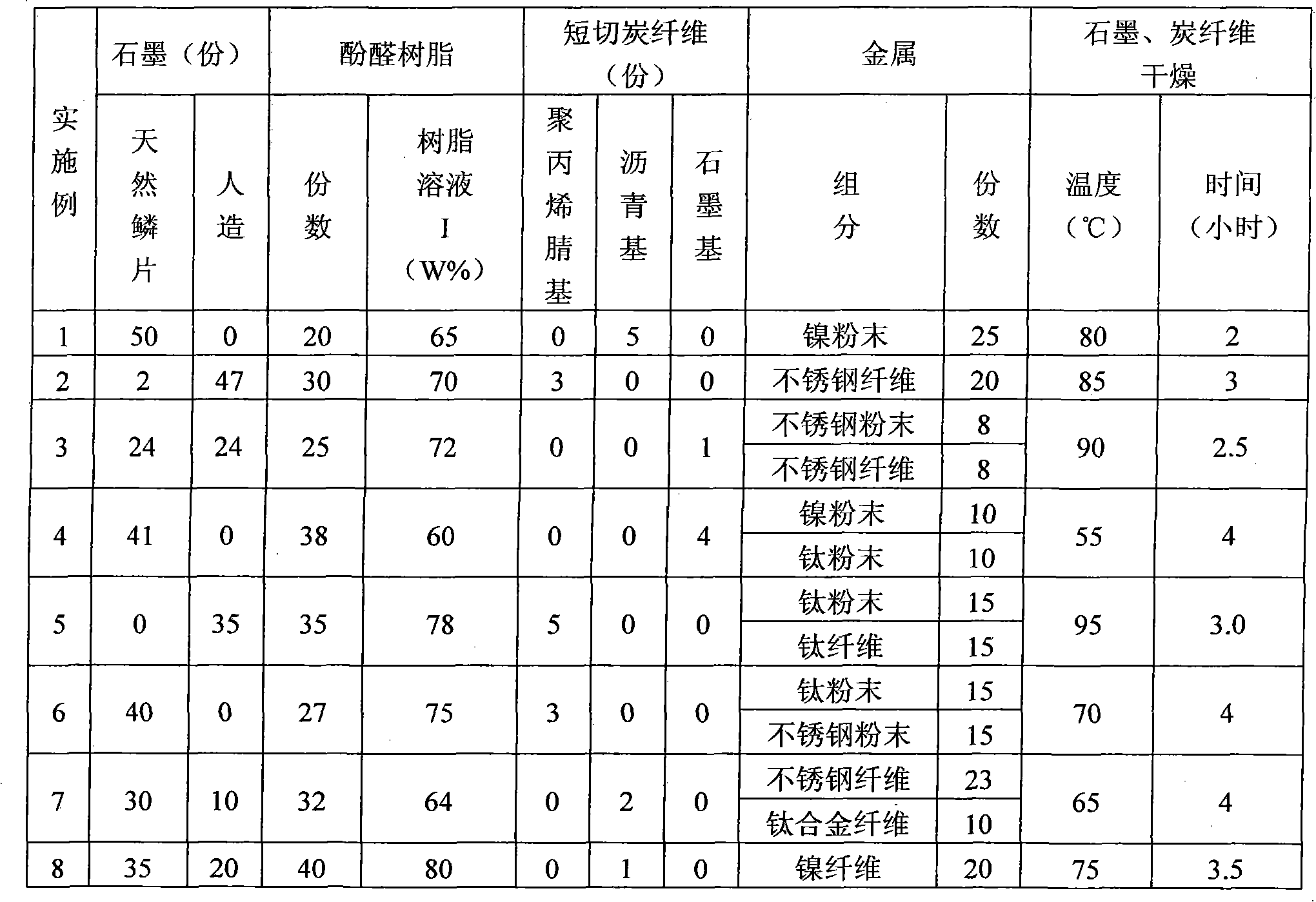

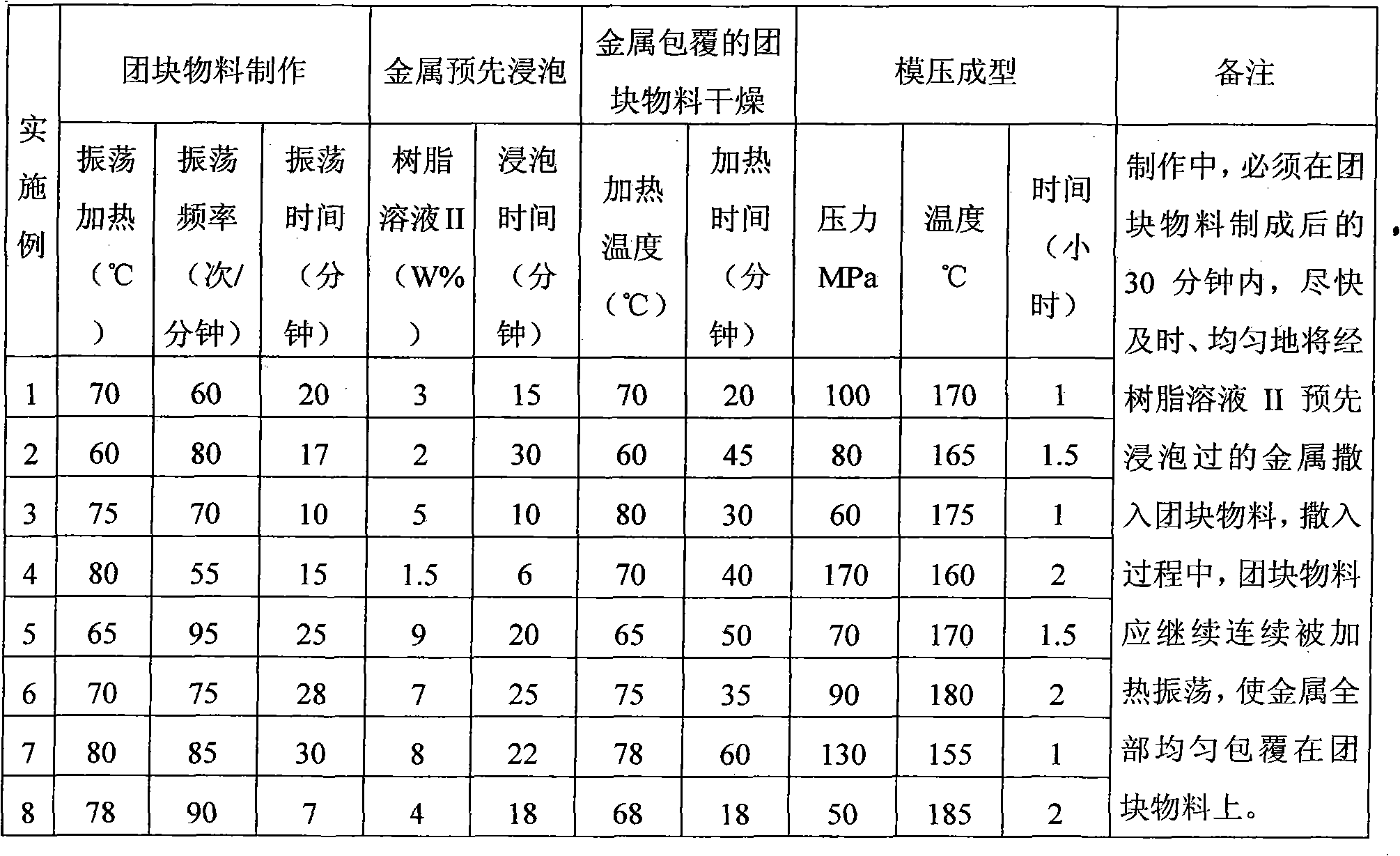

Examples

Embodiment 1

[0031] Embodiment 1, the preparation method of the composite bipolar plate that proton exchange membrane fuel cell is used is as follows in sequence:

[0032] First, raw material pretreatment, put 50 parts of natural flake graphite and 5 parts of pitch-based chopped carbon fiber in a drying oven, and dry at 80°C for 2 hours to remove the moisture absorbed by the raw material, and dry it for use;

[0033] Second, prepare the resin solution I, dilute 20 parts of the phenolic resin with dehydrated alcohol, prepare the resin solution I whose mass percent concentration is 65%;

[0034] The 3rd, the natural flaky graphite that is dried for use and pitch base chopped fiber and resin solution 1 are put into fully mixing in the mixer, make compound;

[0035] Fourth, the production of agglomerate materials, place the mixture on a constant temperature oscillator, oscillate for 20 minutes at 70°C, and the oscillation frequency is 60 times / min, and make an irregularly shaped agglomerate wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com