Method for arranging semi-integral hidden expansion joint for abutment and bridge girder

A semi-integral, hidden technology, applied in the direction of bridge construction, bridges, bridge parts, etc., can solve the problems of bridge structure being easily damaged, endangering bridge safety, bridge service life, bridge management inconvenience, etc., to achieve enhanced resistance to various The ability of catastrophic events, good social and economic benefits, and the effect of uniform distribution of live load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0039] Embodiment two: basically the same as embodiment one, the difference is:

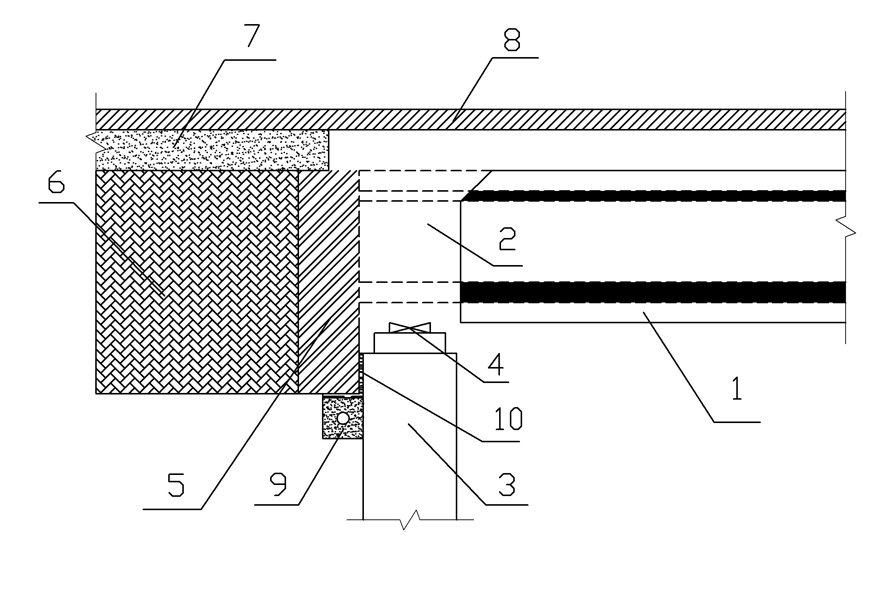

[0040] A method for setting hidden expansion joints of semi-integral abutment bridges according to the present invention differs from Embodiment 1 in that:

[0041] Step d: the thickness of the board 7 is 28cm; the thickness of the asphalt waterproof layer 8 is 8cm; the contact surface between the end of the board and the road surface is provided with a joint with a width of 3cm filled with asphalt;

[0042] Step e: fill the gap between the back wall 5, the dam soil 6 and the rigid semi-integral abutment 3 with ethylene-vinyl acetate copolymer EVA foam material 10 .

Embodiment 3

[0043] Embodiment three: basically the same as embodiment one, the difference is:

[0044] A method for setting hidden expansion joints of semi-integral abutment bridges according to the present invention differs from Embodiment 1 in that:

[0045] Step d: the thickness of the board 7 is 32cm; the thickness of the asphalt waterproof layer 8 is 12cm; the contact surface between the end of the board and the road surface is provided with a joint with a width of 2cm filled with asphalt;

[0046] Step e: fill the gap between the back wall 5, the dam soil 6 and the rigid semi-integral abutment 3 with ethylene-vinyl acetate copolymer EVA foam material 10 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com