Heavy metal zinc polluted soil curing agent taking industrial waste carbide slag as raw material

A technology of waste calcium carbide and curing agent, applied in the restoration of polluted soil, agriculture, organic fertilizer, etc., can solve the problems of poor durability, poor curing effect and high cost of cured soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

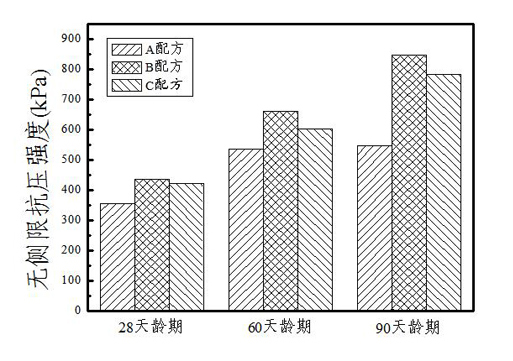

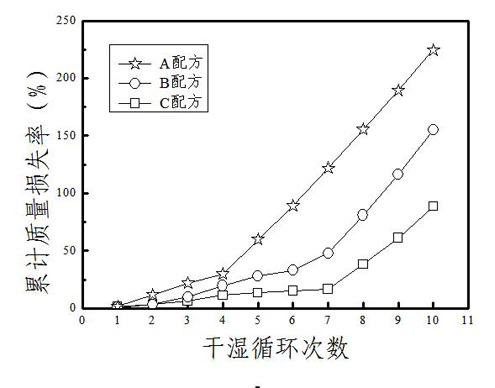

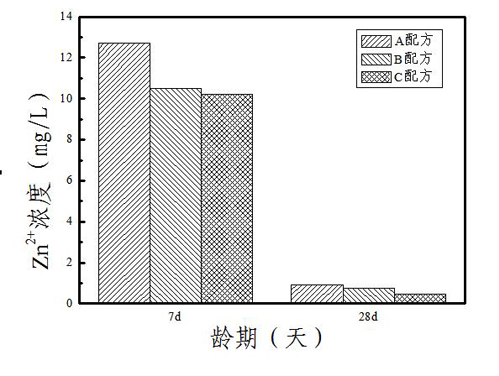

Embodiment 1

[0015] A heavy metal zinc-contaminated soil solidifying agent using industrial waste carbide slag as raw material, comprising: ordinary Portland cement and industrial waste carbide slag, the mass percentage of which is: 70%-80%: 20%-30%, in this implementation In the example, the mass percent of ordinary Portland cement and industrial waste carbide slag is: 70%: 30%, 80%: 20% or 72%: 28%, and the ordinary Portland cement can be P.O.32.5 ordinary silicon Salt cement and carbide slag are completely dry.

Embodiment 2

[0017] A solidification agent for heavy metal zinc-contaminated soil using industrial waste carbide slag as raw material, the solidification agent is composed of ordinary Portland cement, industrial waste carbide slag and sodium-based bentonite, wherein ordinary Portland cement and industrial waste carbide slag The mass percentage is: 70%-80%: 20%-30%, the mixing amount of sodium bentonite is not more than 15% of the sum of ordinary portland cement and industrial waste calcium carbide slag mixing amount, in the present embodiment , the mass percentage of ordinary Portland cement and industrial waste carbide slag is: 70%: 30%, 80%: 20% or 75%: 25%; the mixing amount of sodium bentonite is ordinary Portland cement and industrial waste 15%, 12%, 0.1% or 7% of the sum of carbide slag additions.

[0018] According to the above formula, the present invention mixes it evenly to obtain the finished curing agent. The dosage of curing agent is 15% or 18% (quality of curing agent / qualit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com