Novel coal permissible detonating cord

A detonating cord and coal mine technology, applied in the direction of detonating cord, etc., can solve the problems of poor safety and reliability of combustible gas, high explosion temperature of drug core, poor safety and reliability, etc., to prolong deflagration response time, reduce detonation temperature, Guarantee the effect of safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

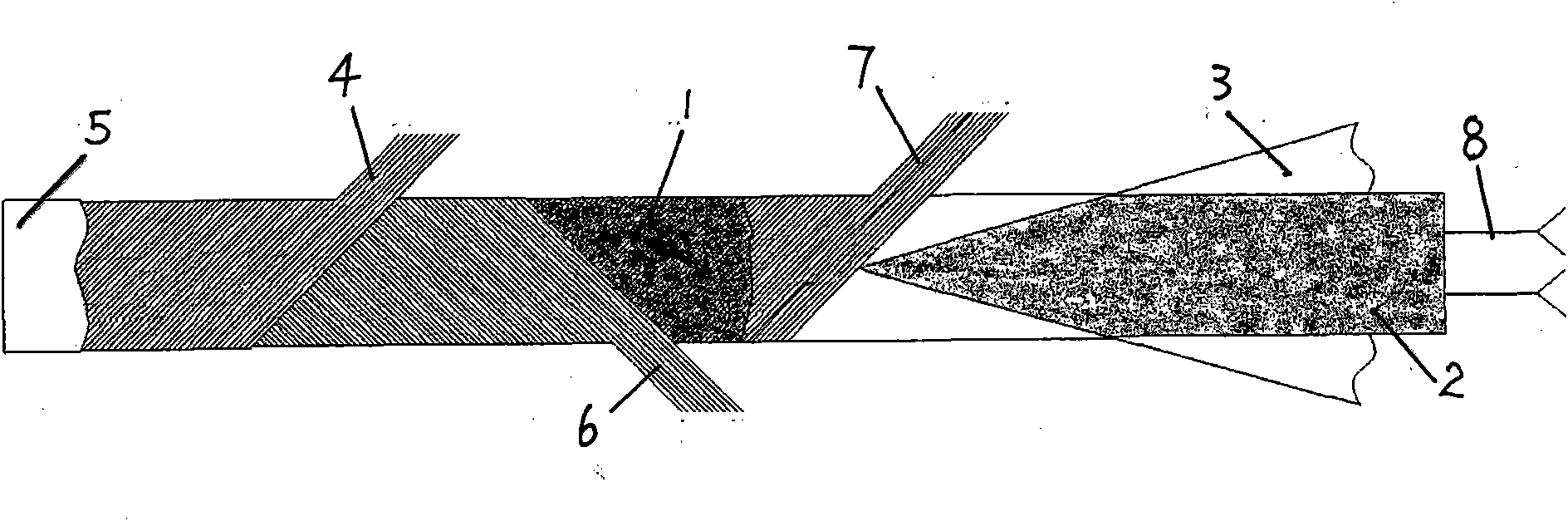

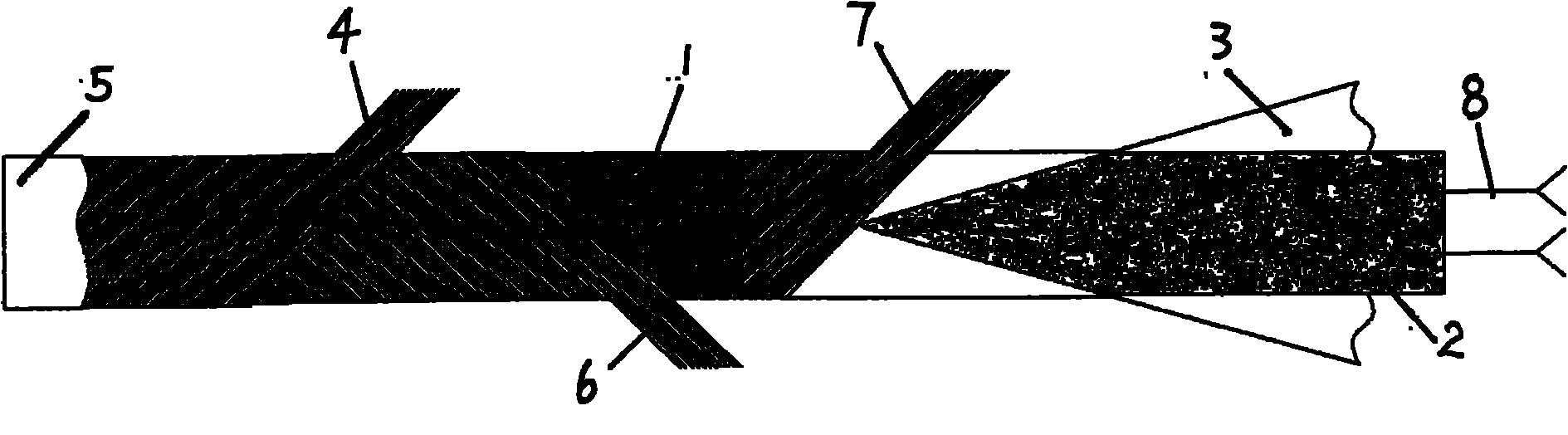

[0009] A new type of detonating cord for coal mines, the drug core formula weight ratio is: 3% to 10% of halogenated linear alkanes or halogenated cycloalkanes, the particle size is less than 40 to 100 mesh, mixed with 90% to 97% of high-energy charges Uniform; the formula weight ratio of the flame suppressant is: NaCI50%~70%, ABC dry powder 30%~50% or KH 2 PO 4 Accounting for 30%~50%, all are granules, mixed evenly, the particle size is 25~150 mesh, or 100% use NH 4 CI, the particle size is 25-150 mesh; the flame extinguishing agent of the jacket adopts a concentric structure, that is, the outer coating of the flame extinguishing agent layer and the drug core are concentrically coated, and the amount of the coated flame extinguishing agent is 11.0-14.0g / m; The covering material is made of cotton fiber or PET filament tow or PET film.

[0010] structured as figure 1 As shown, the allowable detonating cord in this coal mine has the following characteristics: the main compone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com