Polycrystalline silicon production device and method

A production device and production method technology, applied in the direction of silicon, etc., can solve the problems of high pollution, complex process, high impurity content, and achieve the effects of high activity, good spatial uniformity, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

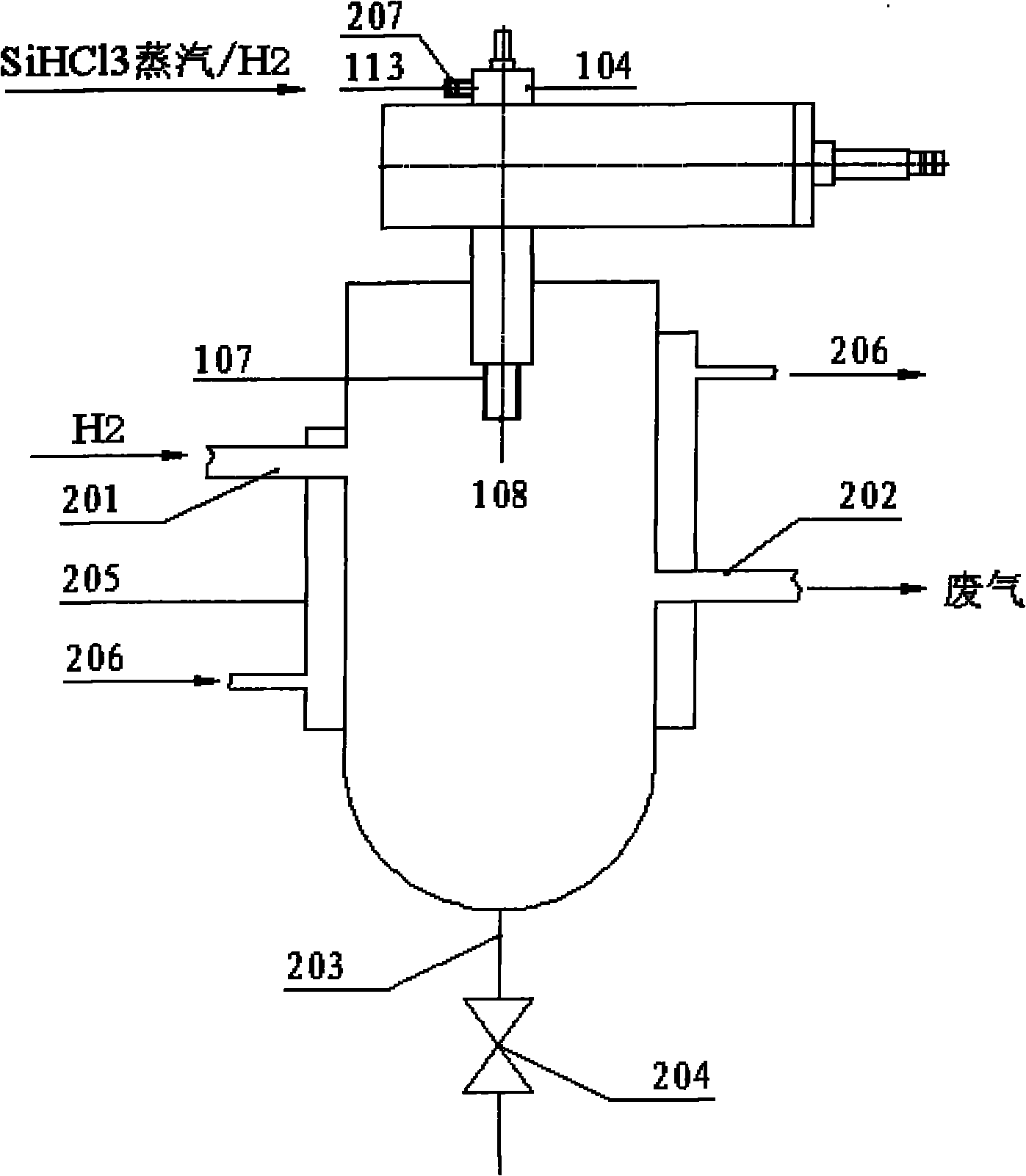

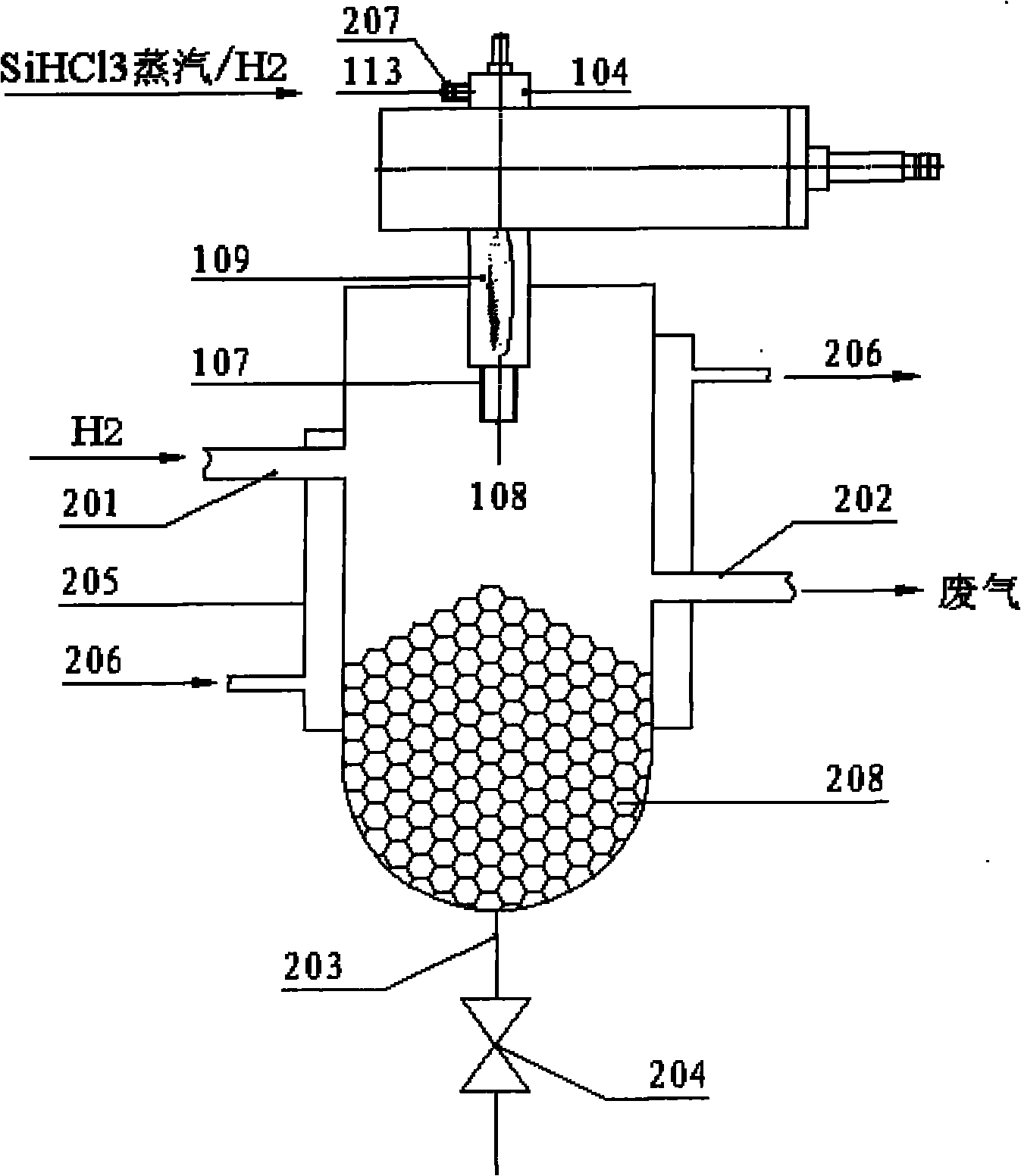

[0035] A polysilicon production device, comprising a polysilicon solidification receiving container, and a microwave surface wave plasma torch as a reactor, the polysilicon solidification receiving container receives the polysilicon generated by the microwave surface wave plasma torch;

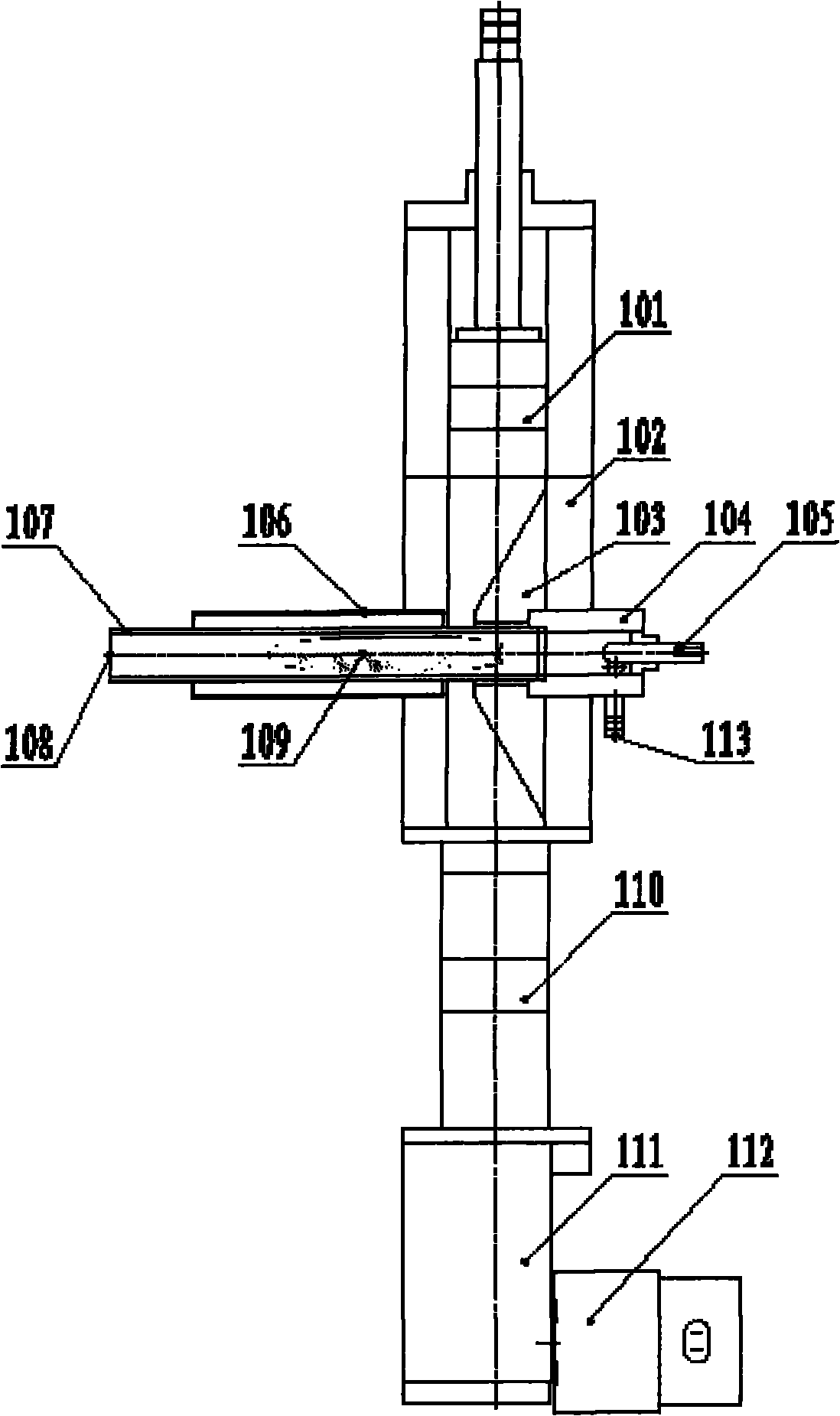

[0036] Such as figure 1 , figure 2 and image 3 shown. The microwave surface wave plasma torch includes a rectangular waveguide 102, and one end of the rectangular waveguide 102 is equipped with a microwave generation and transmission device for transmitting microwaves into the rectangular waveguide 102. A coaxial excitation cavity 111, a microwave tube 112 is installed on the side wall of the excitation cavity 111. The other end of the rectangular waveguide 102 is slidably installed with a short-circuit piston 101, and the inner wall of the rectangular waveguide 102 has an arched channel compression block 103, and the side wall of the rectangular waveguide 102 where the channel compressio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com