Water-saving rice washing barrel

A technology for washing rice and barrels, applied in application, grain processing, grain milling, etc., can solve problems such as excessive water consumption, and achieve the effects of saving water resources, low resistance, and not easy to stagnate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

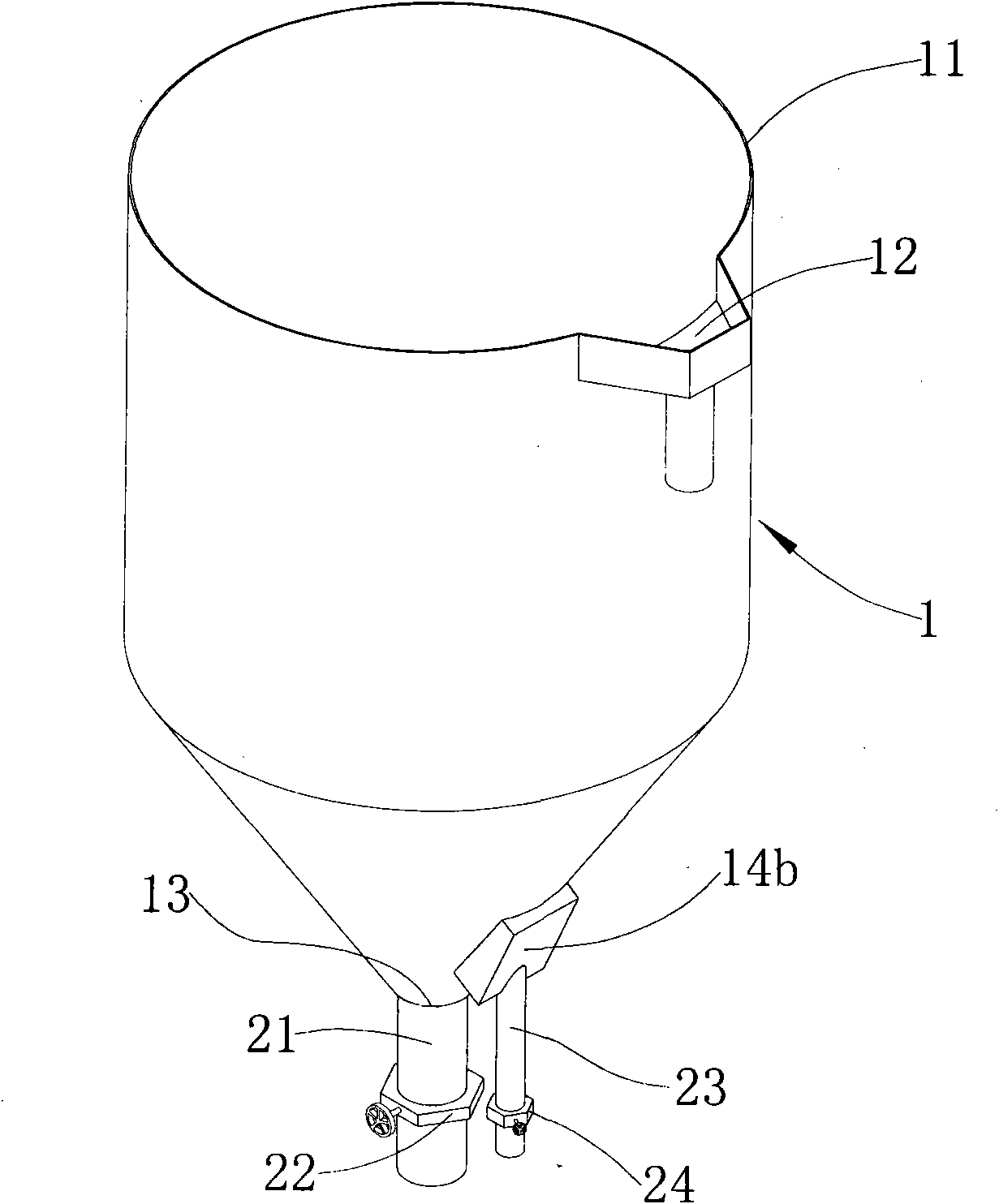

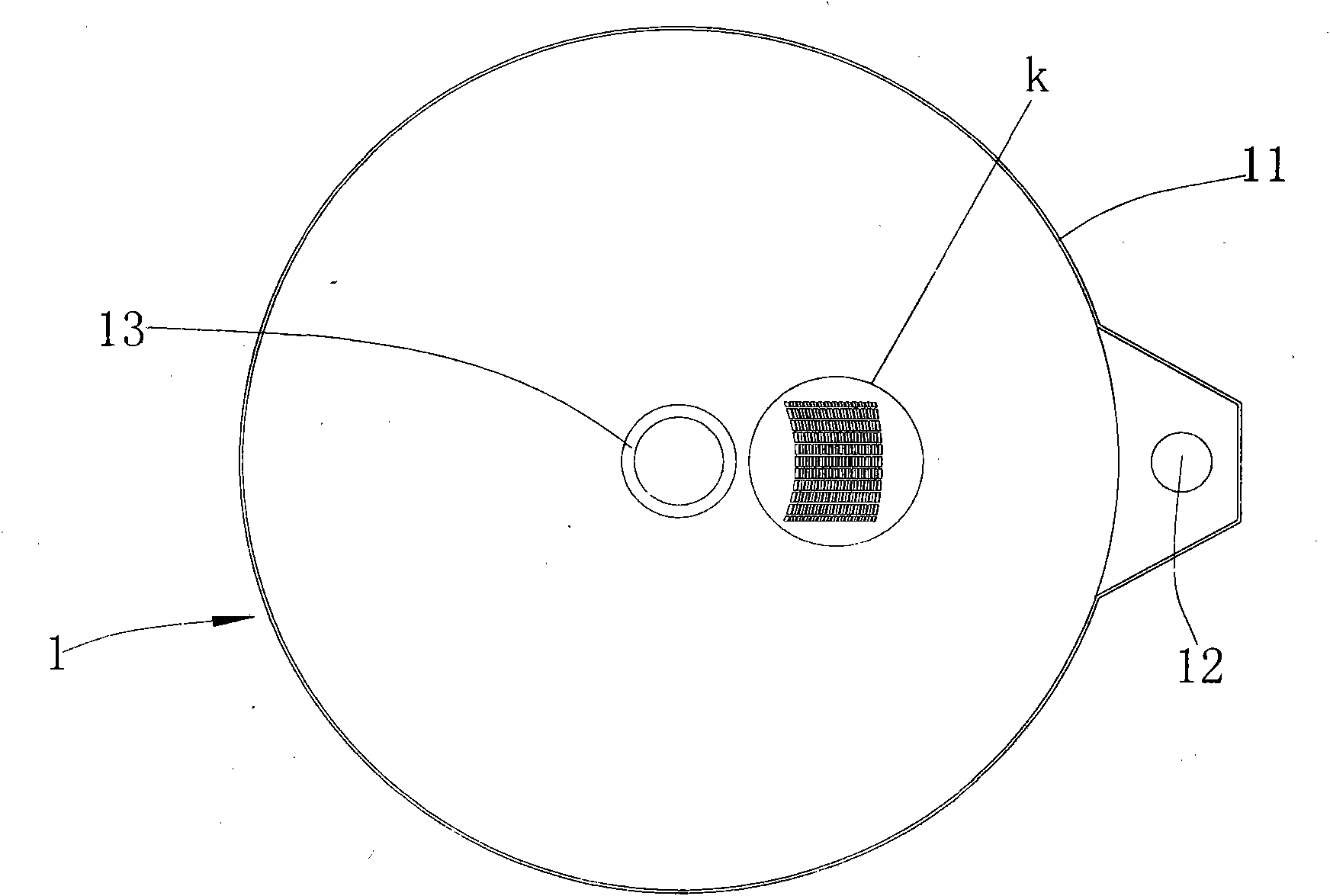

[0014] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

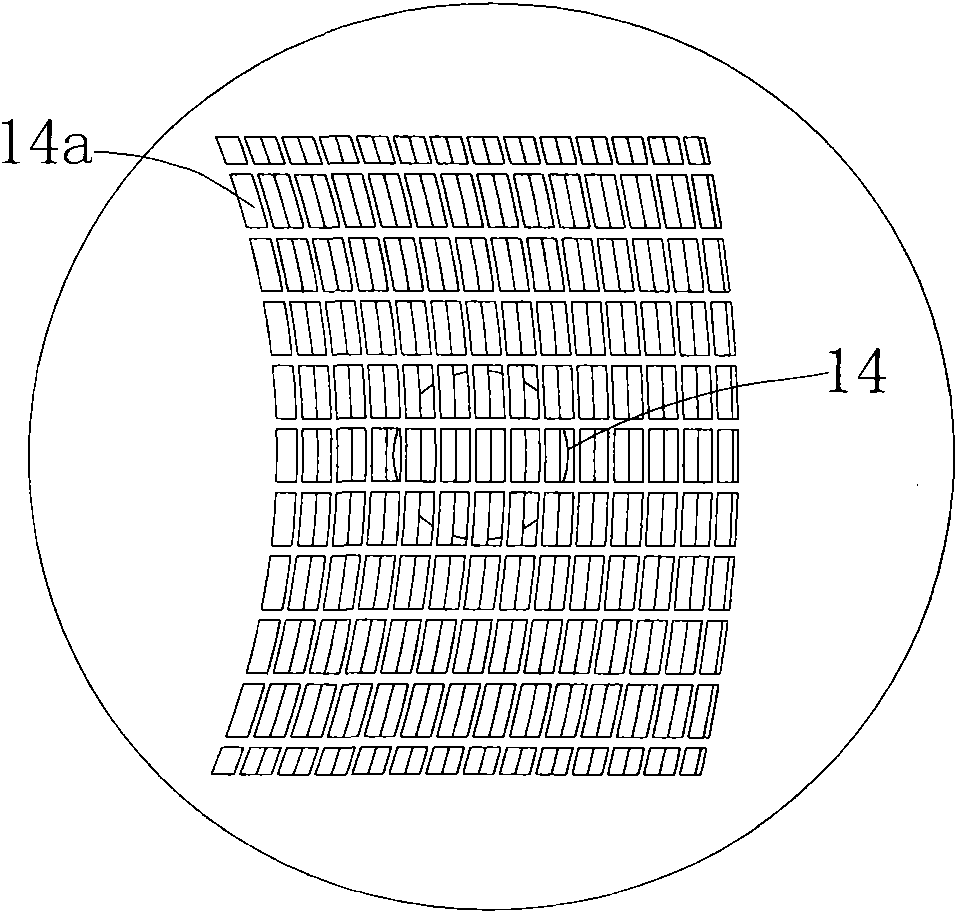

[0015] see Figure 1-4 , the barrel body 1 of this rice washing barrel is placed vertically. The upper end 11 of the staving body 1 is open and the outer edge is provided with an overflow port 12. The bottom of the staving body 1 is in an inverted cone shape. The lower end of the staving body 1 is provided with a rice outlet 13. Connected, the rice outlet pipeline 21 is provided with a rice outlet control valve 22. The bottom of the staving body 1 is provided with a water outlet 14 near the rice outlet 13, and the inwall of the staving body 1 is equipped with a filter screen 14a for keeping rice at the place corresponding to the water outlet 14. The outer wall of the staving 1 is provided with a protective cover 14b corresponding to the water outlet 14 and the water outlet 14 is covered. The water outlet 14 is communicated with the outlet pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com