Dissolving method of hydrophobically associating polymer and special stretching device thereof

A technology of hydrophobic association and stretching device, which is applied in the direction of mixing methods, dissolution, chemical instruments and methods, etc., can solve the problems of accelerating the dissolution rate of hydrophobic association polymers and the inability to completely dissolve the solid powder of hydrophobic association polymers, etc. To achieve the effect of increased recovery and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, stretching device

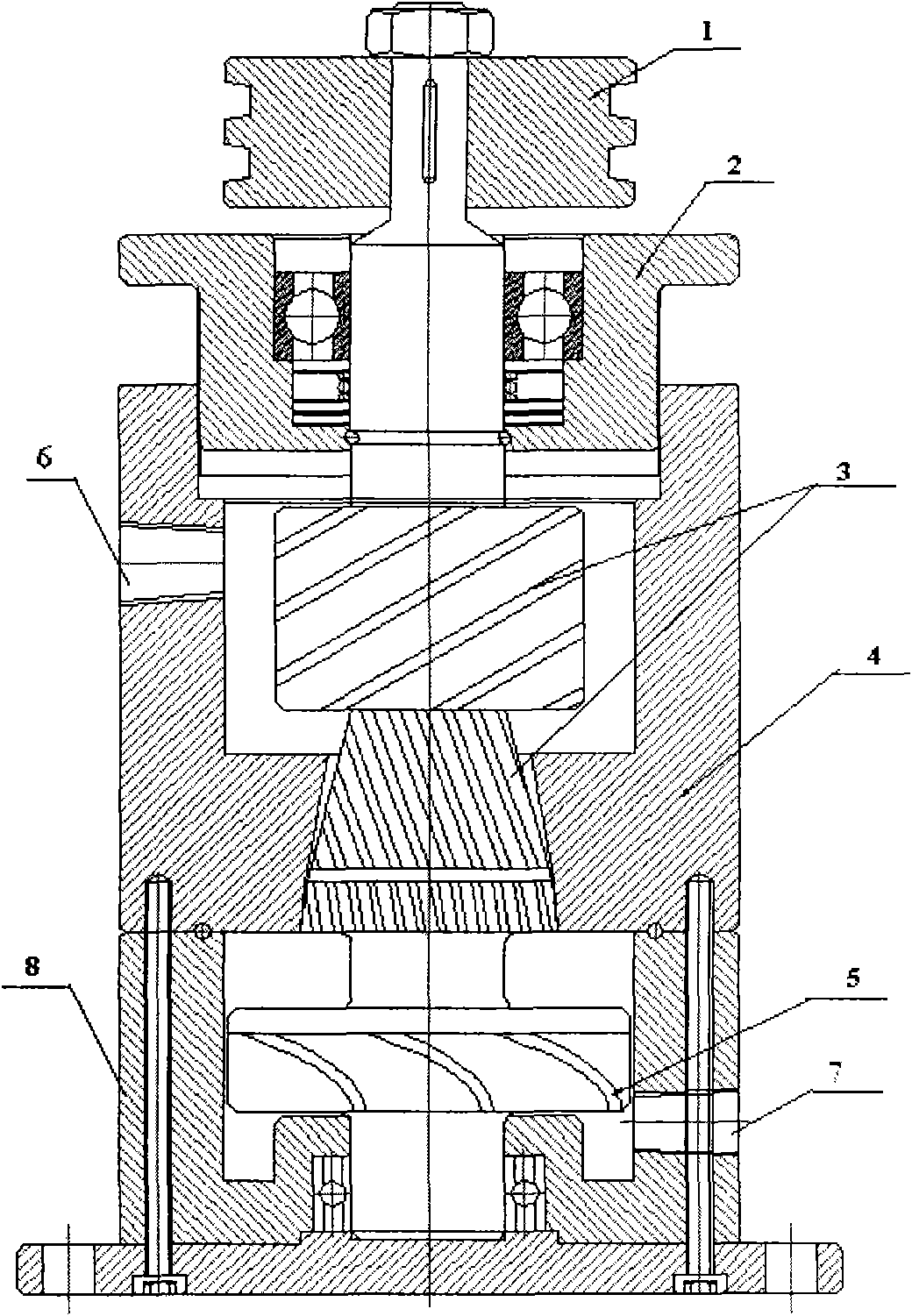

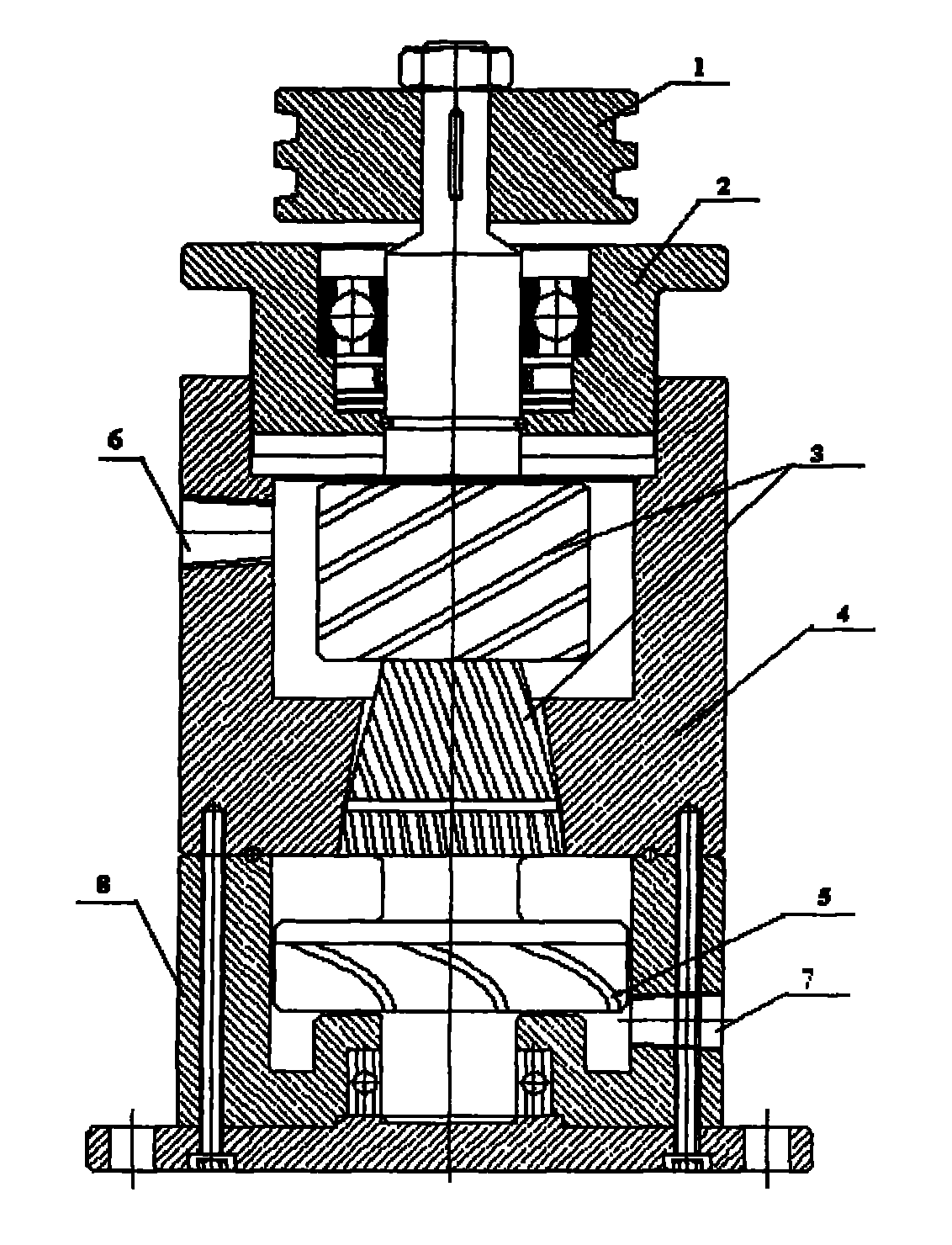

[0029] The structural representation of stretching device of the present invention is as figure 2 As shown, each mark in the figure is as follows: 1 belt pulley, 2 adjusting ring, 3 moving grinding wheel, 4 fixed grinding wheel, 5 impeller, 6 inlet, 7 outlet, 8 base.

[0030] The stretching device of the present invention comprises a fixed grinding wheel 4 arranged on a base 8, a movable grinding wheel 3 arranged inside the fixed grinding wheel 4, and its lower part is a circular platform; a distance is provided between the movable grinding wheel 3 and the fixed grinding wheel 4; The top of 3 is provided with an adjustment ring 2, by rotating the adjustment ring 2, the distance at the narrowest point between the movable grinding wheel 3 and the fixed grinding wheel 4 can be adjusted within the range of 150 μm-500 μm, and the remaining distances are not equidistant; The movable grinding wheel 3 is provided with radial grinding teeth (n...

Embodiment 2

[0032] Embodiment 2, the dissolution of hydrophobic association polymer AP-P4

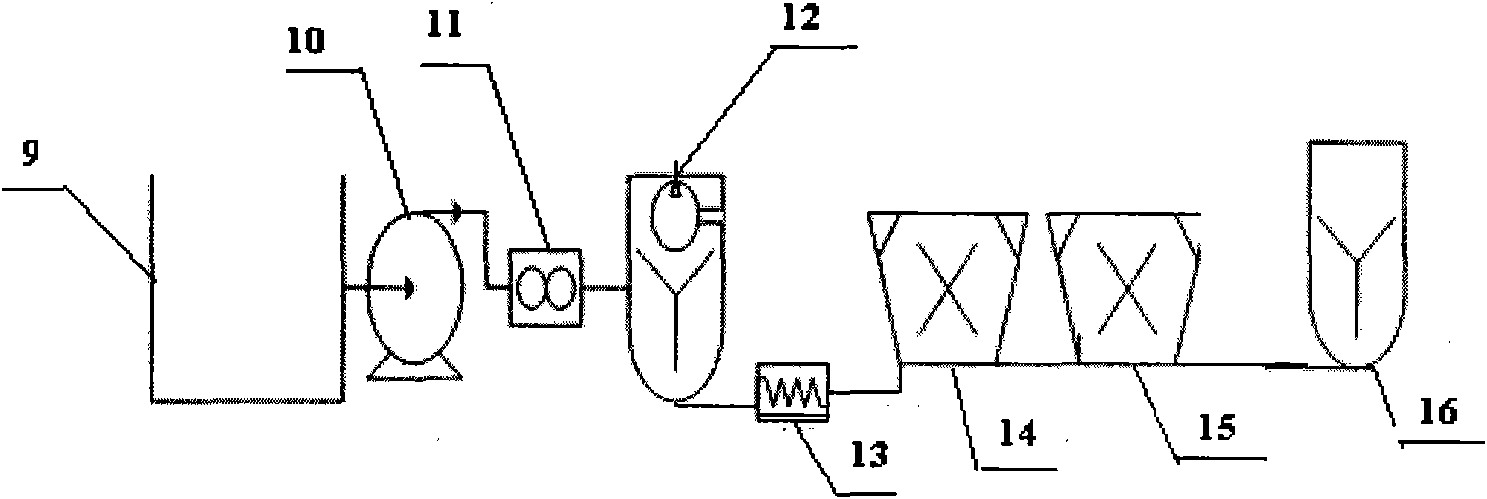

[0033] The flow chart of the dissolving process of this embodiment is as figure 1 shown. The marks in the figure are as follows: 9 pool, 10 centrifugal pump, 11 flow meter, 12 mixing tank, 13 screw pump, 14, 15 stretching device, 16 aging tank.

[0034] The stretching device 14 and the stretching device 15 used in this embodiment are all the stretching devices described in embodiment 1; the distances at the narrowest points between the movable grinding wheel and the fixed grinding wheel in the two stretching devices are respectively 400 μm and 200 μm.

[0035] The brine in the pool 9 is heated to 35°C, and the brine is pumped into the mixing tank 12 under the action of the centrifugal pump 10, and a flow meter 11 is connected between the centrifugal pump 10 and the mixing tank 12 to control the flow rate of the brine; Next, the hydrophobic association polymer AP-P4 powder is quickly mixed with sal...

Embodiment 3

[0038] Embodiment 3, the dissolving of hydrophobic association polymer AP-P4

[0039] The flow chart of the dissolving process of this embodiment is as figure 1 shown. The marks in the figure are as follows: 9 pool, 10 centrifugal pump, 11 flow meter, 12 mixing tank, 13 screw pump, 14, 15 stretching device, 16 aging tank.

[0040] The stretching device 14 and the stretching device 15 used in this embodiment are all the stretching devices described in embodiment 1; the distances at the narrowest points between the movable grinding wheel and the fixed grinding wheel in the two stretching devices are respectively 500 μm and 168 μm.

[0041] The brine in the pool 9 is heated to 45°C, and the brine is pumped into the mixing tank 12 under the action of the centrifugal pump 10, and a flow meter 11 is connected between the centrifugal pump 10 and the mixing tank 12 to control the flow rate of the brine; Next, the hydrophobic association polymer AP-P4 powder is quickly mixed with sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com