Novel centrifugal fine water mist spray head

A fine water mist nozzle, centrifugal technology, applied in fire rescue and other directions, can solve the problems of large water consumption, uneven distribution of water mist, poor atomization effect, etc. Immersion effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

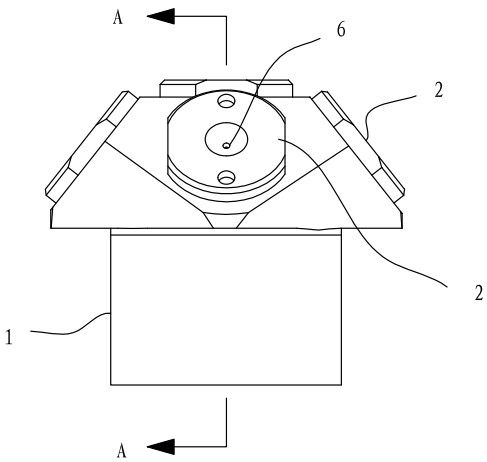

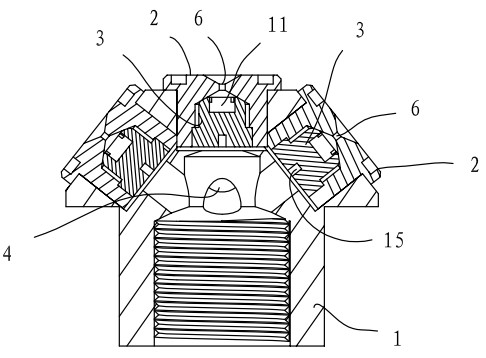

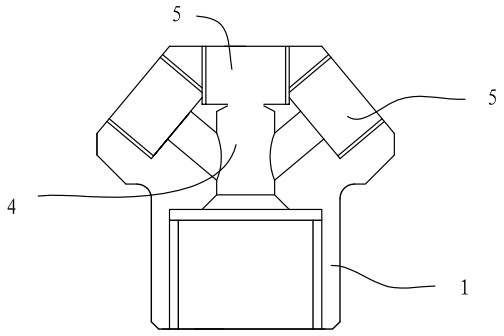

[0022] refer to Figure 1-8 , a new type of centrifugal fine water mist nozzle, including a base 1 with a pentahedron at the end, a nozzle body 2 with a nozzle hole 6 arranged on the base 1 and an atomizing core 3 arranged in the nozzle body 2 . Each surface of the base 1 is provided with a mounting hole 5, and the five nozzle bodies 2 are respectively screwed into the mounting holes 5. The base 1 is respectively provided with five water inlet holes 4, which are respectively connected with five installation holes 5, so that high-pressure water can be introduced into the installation holes 5 respectively. The inside of the nozzle body 2 is provided with a hollow cylindrical inner cavity 7, and the top of the inner cavity 7 is a conical surface 8, the nozzle hole 6 is arranged at the apex of the conical surface 8, and the atomizing core 3 is composed of a core seat 9 and a core The core body 10 is composed of a racetrack shape and is threadedly connected with the inner cavity 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com