Wet scrubber having a compact demister that requires reduced energy demand

A wet scrubber and mist eliminator technology, which is applied to flushing wellbore, chemical instruments and methods, wellbore/well components, etc., can solve the problems of heavy mist eliminators, thick filter materials, difficult assembly, etc., and improve the purification effect. , small pressure loss, good wet-through effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

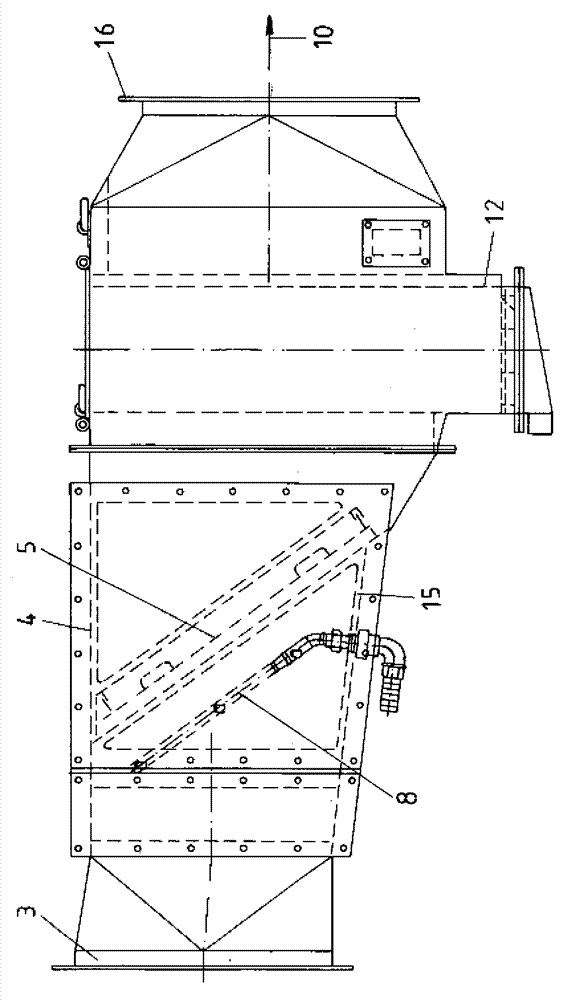

[0027] exist figure 1 In the wet scrubber 1 described in , the scrubber housing 2 is described as open in the area of the demister 5 and closed in the remaining areas. Correspondingly, the demister sub-housing 4 with the demister 5 is connected to the air inlet connection 3, wherein the dust-laden air humidified by the humidification nozzles 6, 7 is then guided in the air direction to the droplets. In the catcher 11, its droplet catcher sub-housing 12 has an obliquely constructed bottom to which the sewage outlet 13 is connected.

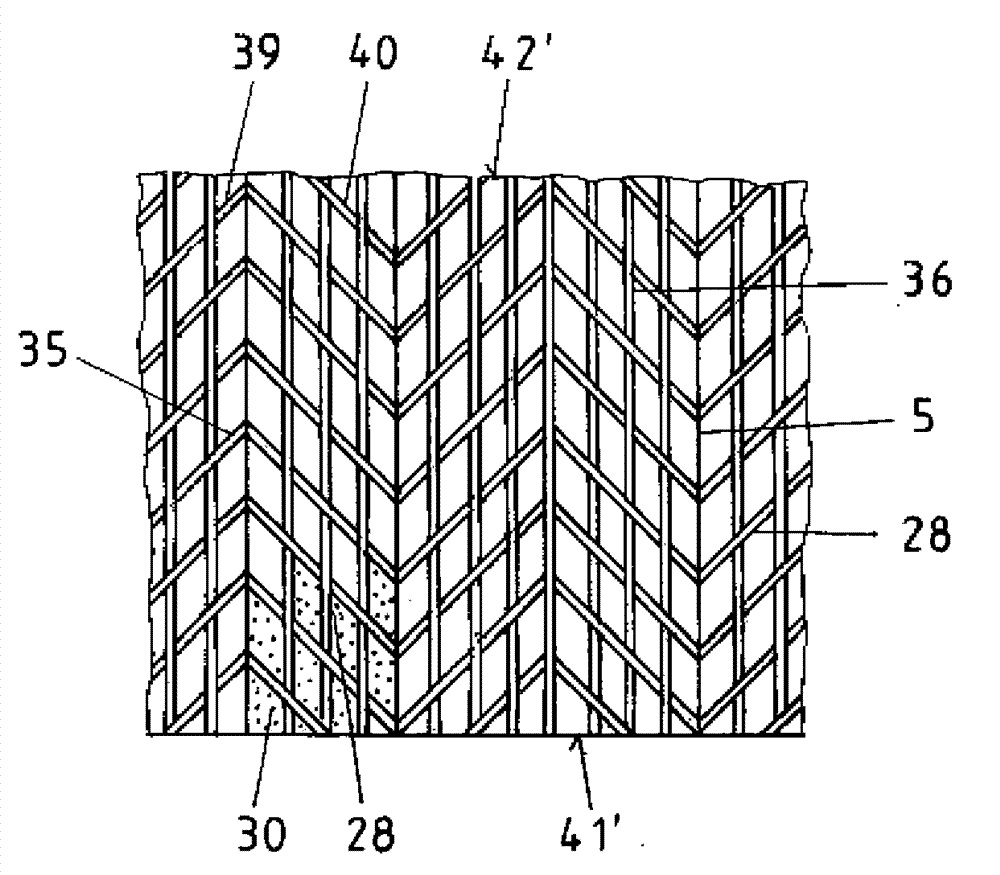

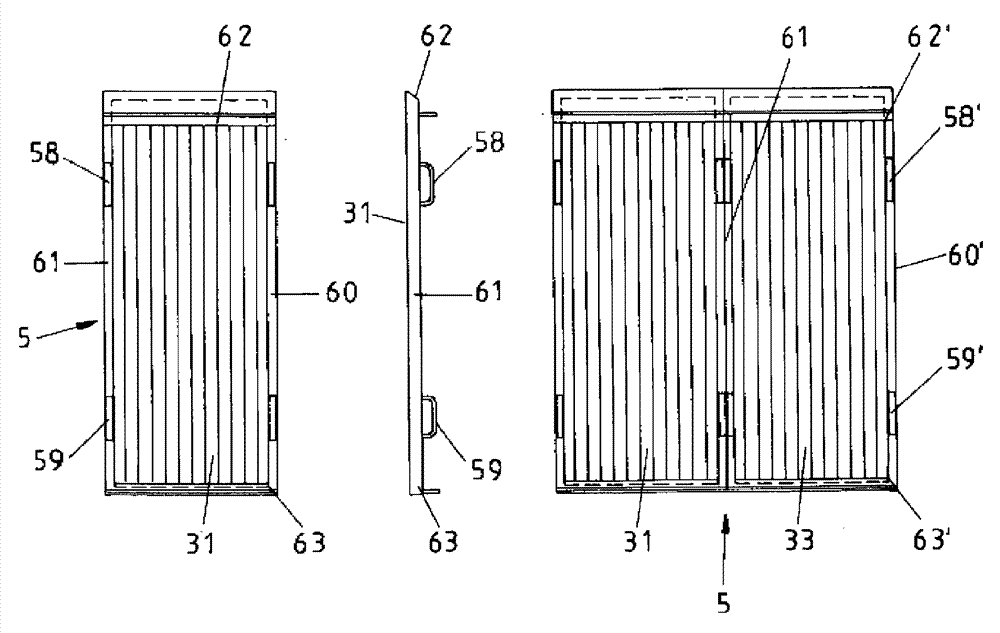

[0028] exist figure 1 The surface 26 of the filter element 25 of the mist eliminator 5 is not recognizable in the wavy configuration. This is more evident from the other figures. The humidification nozzles 6 , 7 aligned to the mating surface 26 ′ of the mist eliminator 5 are associated with the nozzle frame 8 and are arranged such that their nozzle openings 9 are directed onto the mist eliminator 5 . here in figure 1 It is further shown in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com