Stator punching sheet for low-speed permanent magnet submersible motor

A technology for stator punching and submersible motors, applied to the static parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., which can solve the difficulties of motor output, strong reverse rotating magnetic field, unreasonable design of fractional slot winding structure, etc. problem, to achieve the effect of novel structure and improved torsional strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

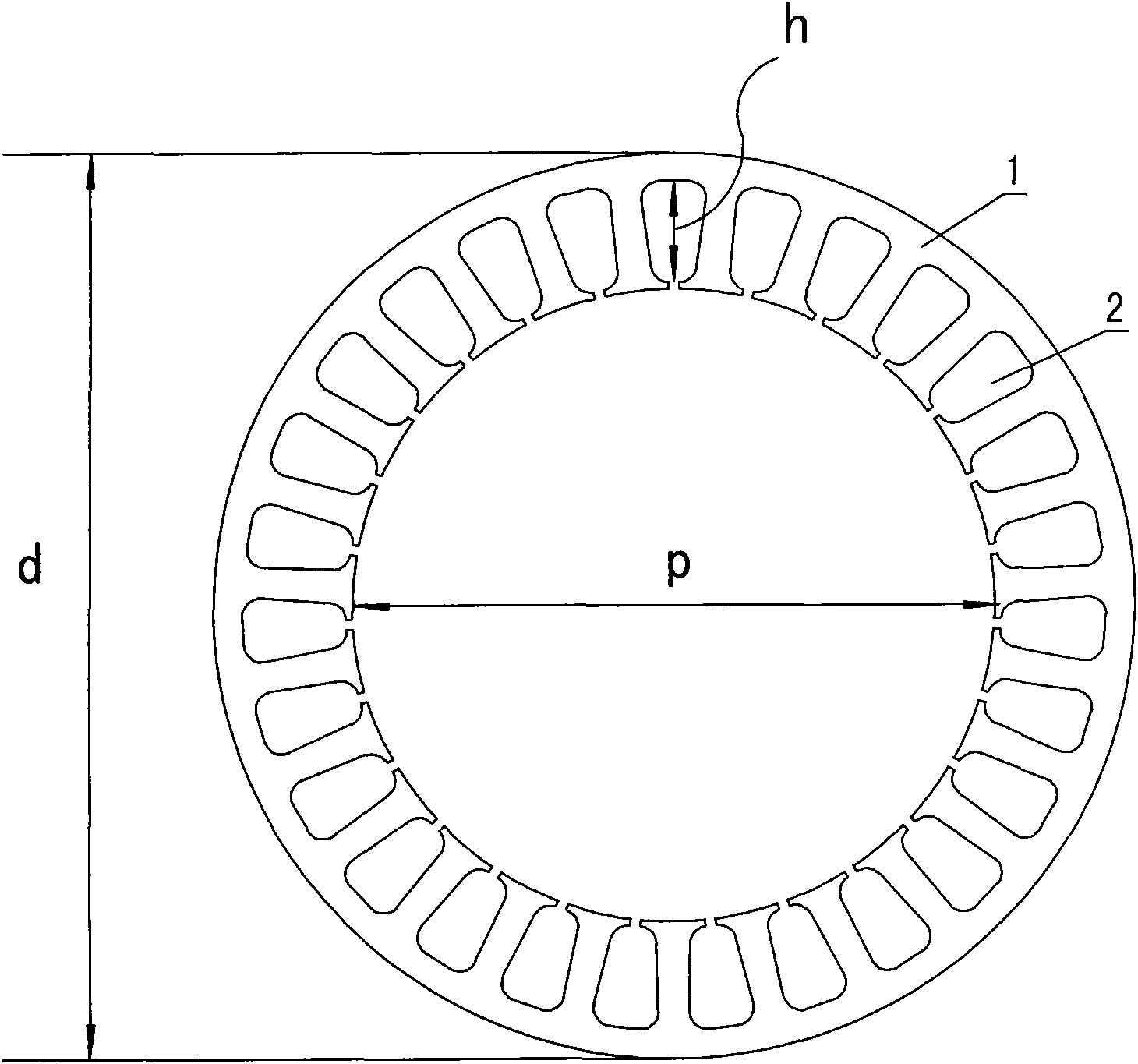

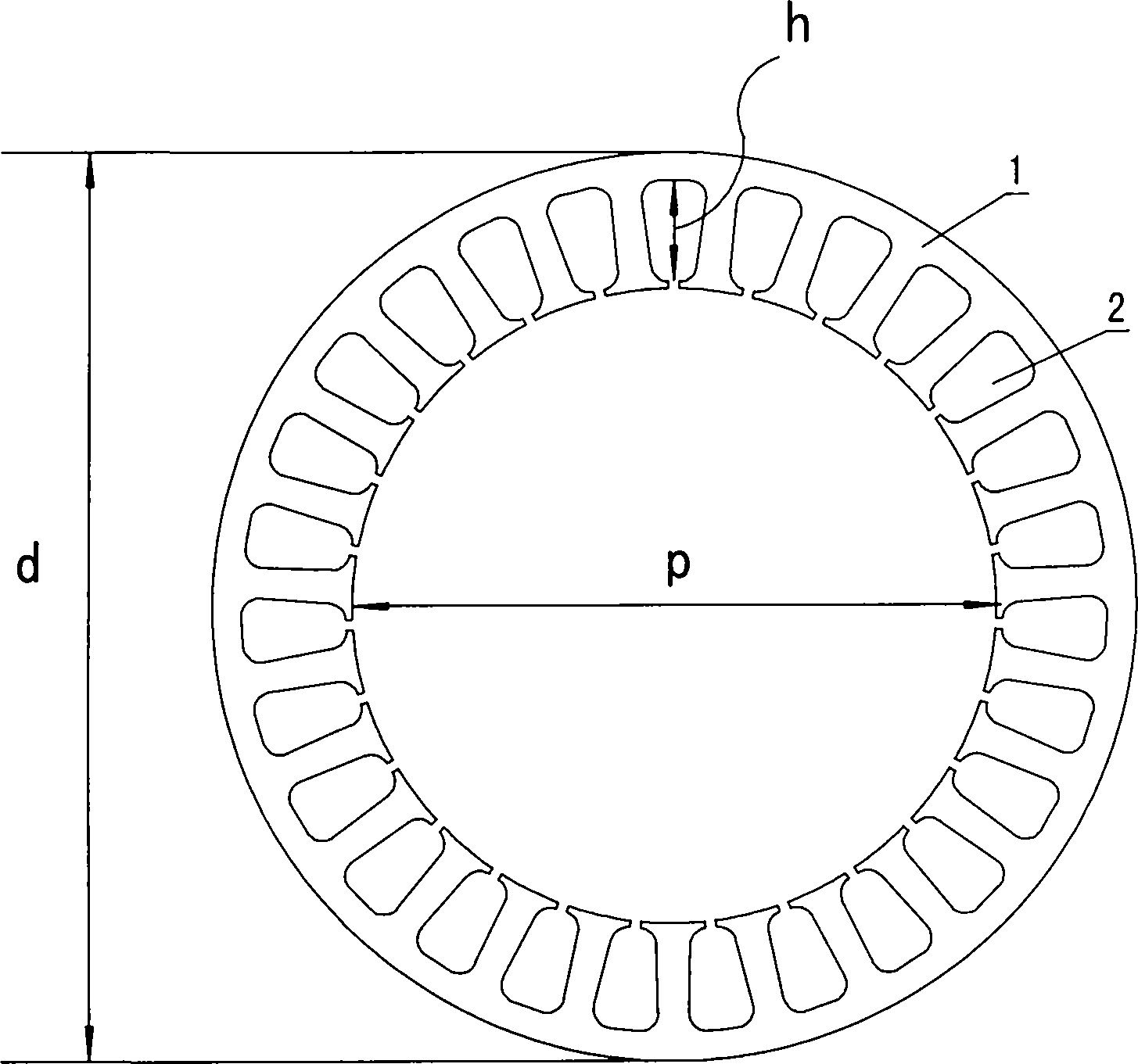

[0017] In the embodiment shown in the figure, the stator punching piece is circular and consists of an annular yoke 1 and 27 wire slots 2 evenly distributed on the annular yoke. Closed notch.

[0018] The diameter of the outer circle of the stator punching sheet is 90-110mm, and the diameter of the inner circle, that is, the inner edge of the annular magnetic yoke, is 60-75mm.

[0019] The outer circle diameter of the stator stamping in the embodiment shown in the figure is d=104.8mm, and the inner circle is the diameter P=72mm along the inner edge of the ring yoke 1 .

[0020] The groove height 12-15mm of this stator punching sheet embedding line groove 2, groove top is flat top.

[0021] As shown in the figure, the slot height of the stator stamping plate of the embodiment is h=12.8mm, the top of the slot is flat, and there are chamfers at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com