Snare drum with phosphor copper drum shell

A drum and phosphor bronze technology, which is applied to percussion instruments, instruments, musical instruments, etc., can solve the problems of increasing production cycle, peeling of surface coating, increasing equipment cost, etc., and achieve the effect of improving grade, crisp sound and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

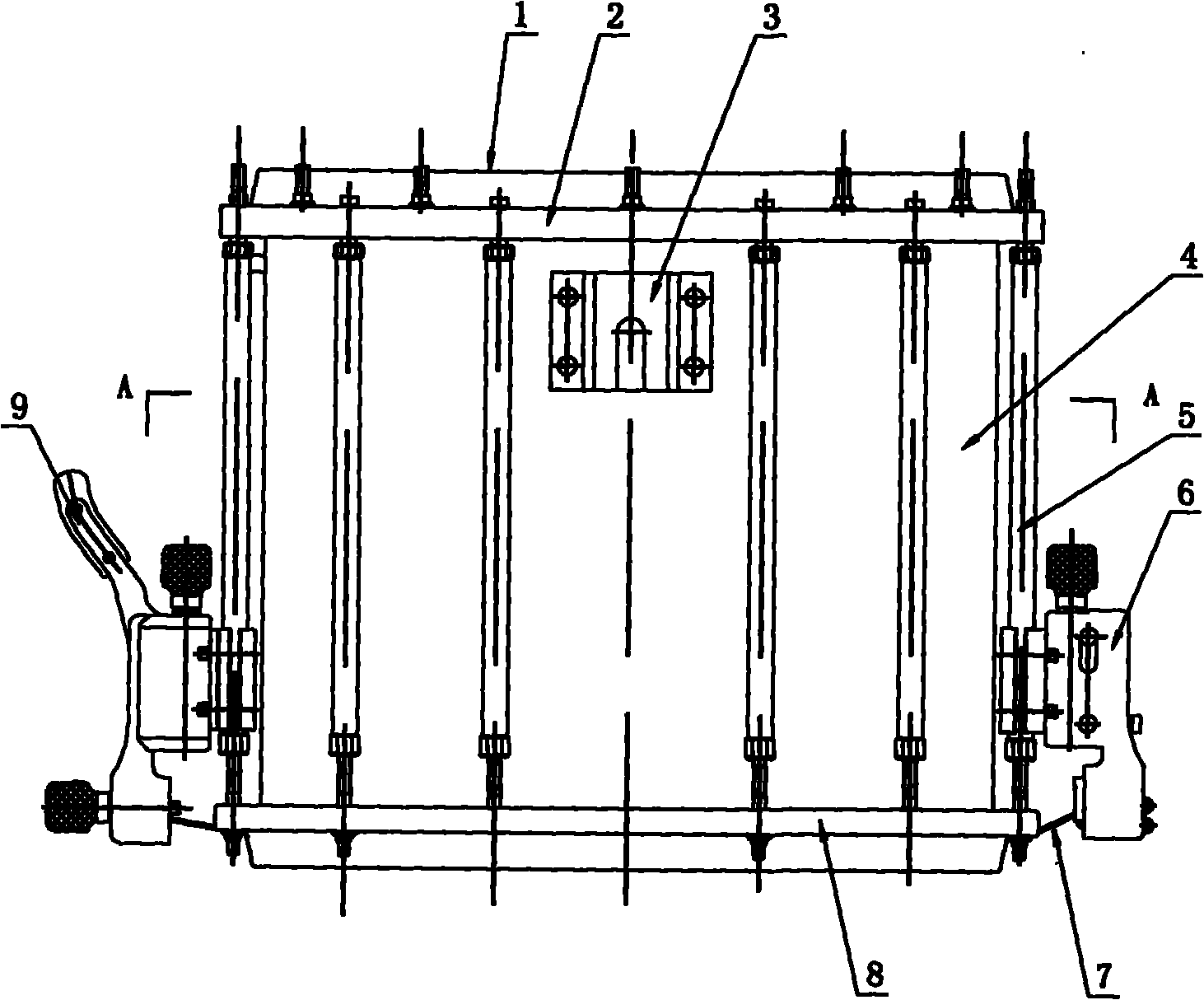

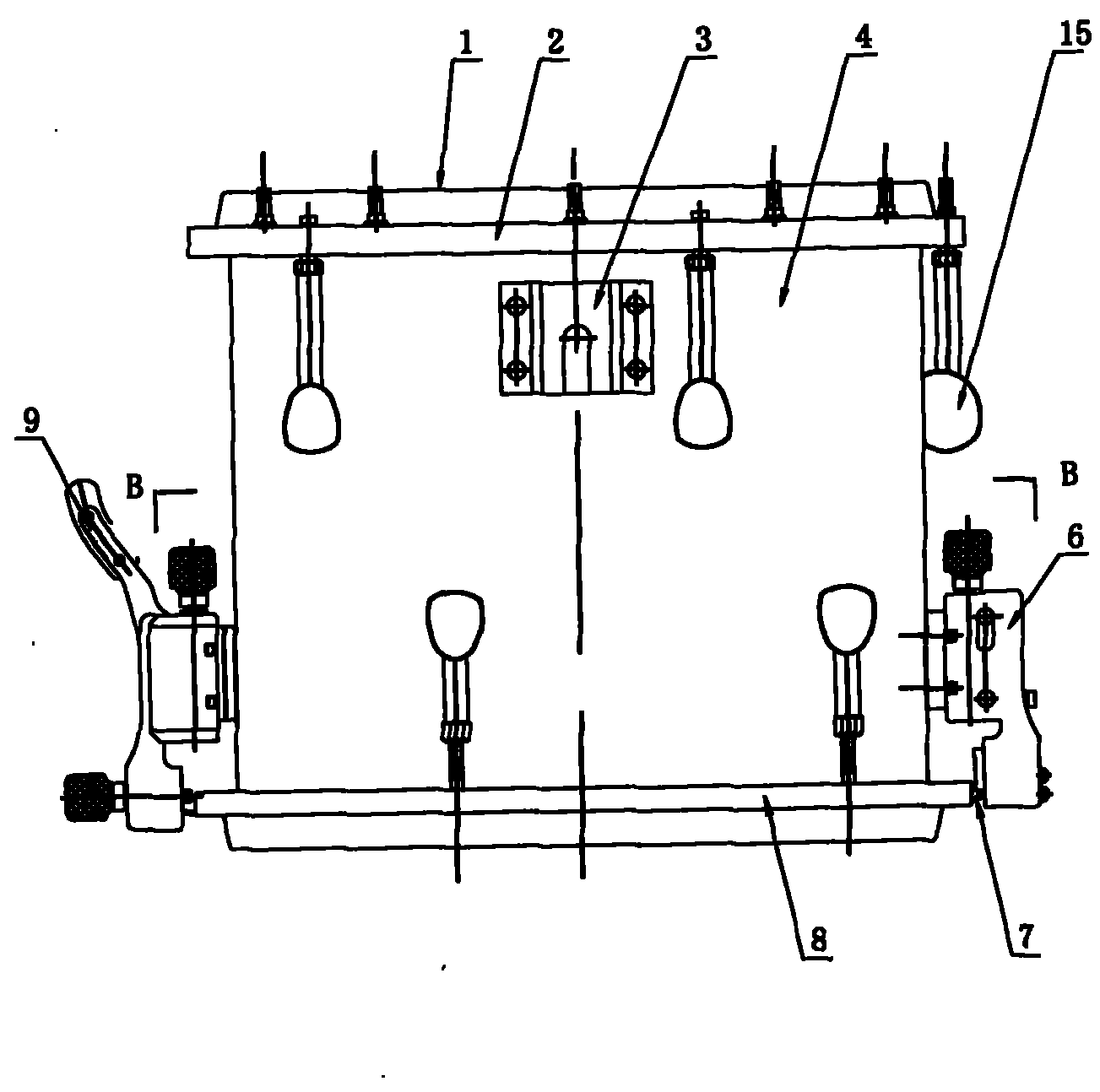

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0024] A snare drum with a phosphor bronze drum such as Figure 1~4 As shown, it includes the percussion surface 1, the snare surface (installed in the lower opening of the drum, not marked in the figure), the upper pressure ring 2, the lower pressure ring 8 and the drum cylinder 4, the percussion surface and the snare surface are coaxial respectively It is fitted on the upper and lower openings of the drum, and is fastened and fixed by the upper clamping ring and the lower clamping ring respectively. The innovation of the present invention is that the drum is made of a layer of phosphor bronze material. The radial thickness of the drum is 1 to 1.2 millimeters, of course, it is also possible to have ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com