Fluorescent sensor for magnesium ions and preparation method thereof

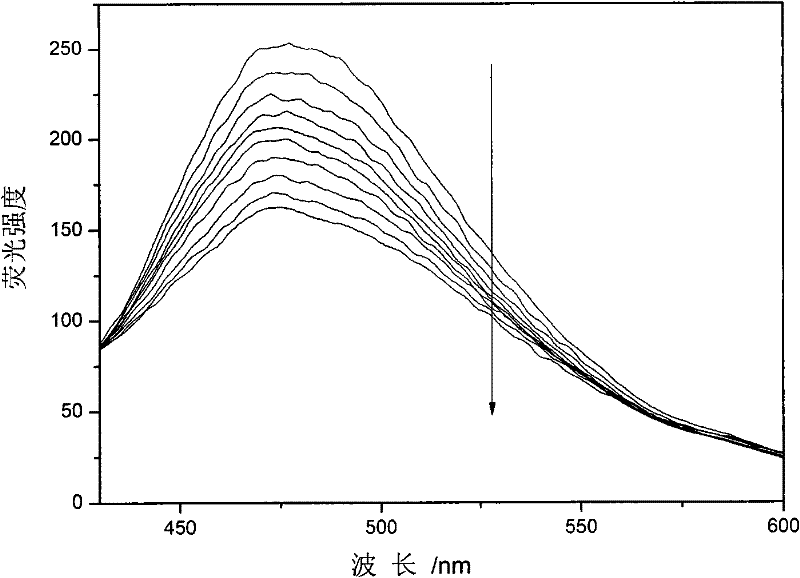

A fluorescent sensor and magnesium ion technology, applied in the direction of fluorescence/phosphorescence, material excitation analysis, etc., can solve the problems of thin-film fluorescence sensor research weakness, etc., and achieve the effect of improving thermal stability and pH application range, not easy to aging, and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

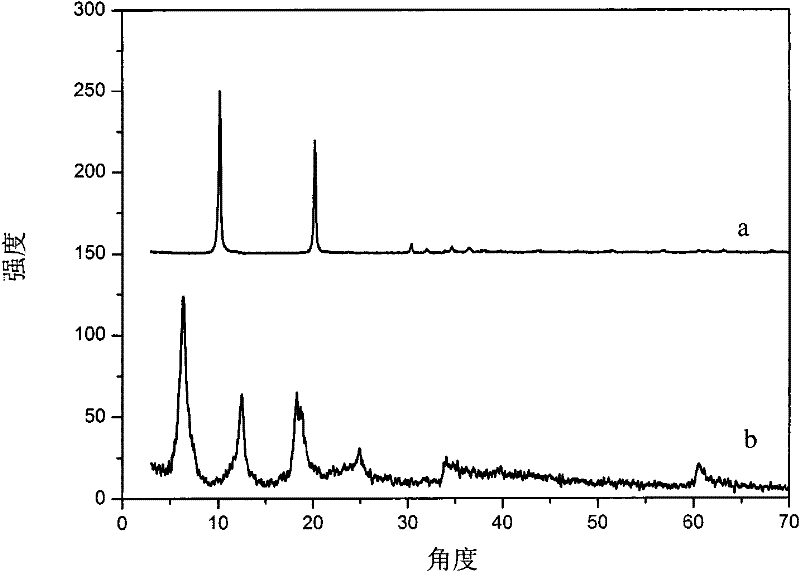

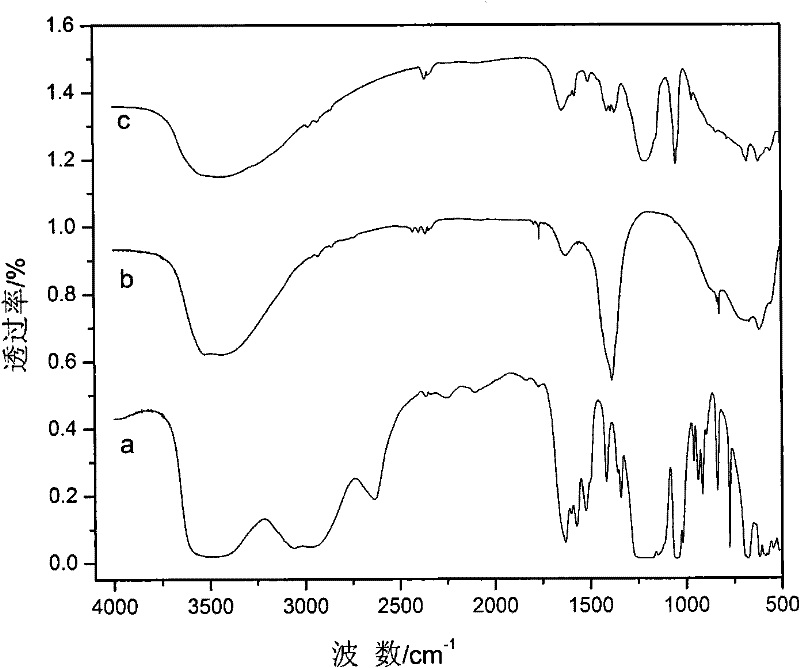

[0023] a. Preparation of hydrotalcite precursor: adopt hydrothermal method, weigh 53.55g Zn(NO 3 ) 2 ·6H 2 O and 33.75gAL(NO 3 ) 3 9H 2 O dissolved in 100ml to remove CO 2 Prepare a saline solution in water; another 21.6g NaOH is dissolved in 100ml to remove CO 2 Prepare NaOH solution in water; add the salt solution and NaOH solution into a high-speed stirring colloid mill and stir for 1 minute to obtain a slurry; place the slurry in a pressure melting bomb, react at 110°C for 10 hours, and centrifuge and wash the product; The chemical formula of the prepared hydrotalcite precursor is Zn 2 Al(OH) 6 (NO 3 )·6H 2 O;

[0024] b. the preparation concentration is 1-naphthylamine-3,6,8-trisulfonic acid solution of 3g / L, after adjusting the pH value of the solution with sodium hydroxide to be 6.5, add the hydrotalcite precursor prepared by 0.5g step a, in N 2 Stir under protection, react at 25°C for 48 hours, the product uses CO 2 Washing with water and centrifuging to ob...

Embodiment 2

[0036] a. with the step a of embodiment 1;

[0037] b. the preparation concentration is 1-naphthylamine-3,6,8-trisulfonic acid solution of 5g / L, the hydrotalcite precursor that 0.8g step a prepares after adding the hydrotalcite precursor of 0.8g step a with sodium hydroxide regulator solution pH value, in N 2 Stir under protection, react at 28°C for 48 hours, the product uses CO 2 Washing with water and centrifuging to obtain 1-naphthylamine-3,6,8-trisulfonic acid intercalated hydrotalcite;

[0038] c. Take 1 g of 1-naphthylamine-3,6,8-trisulfonic acid intercalated hydrotalcite prepared in step b, dissolve it in 80 ml of ethanol solution and sonicate for 6 minutes, put the mixed solution in a high-speed centrifuge, and set the speed at 7500 rpm / min, centrifuged for 6 minutes, and took the upper colloidal solution;

[0039] d. Take 20ml of the upper colloidal solution obtained in step c and place it in the electrochemical deposition liquid pool. 2 The conductive glass FTO s...

Embodiment 3

[0041] a. with the step a of embodiment 1;

[0042] b. the preparation concentration is 1-naphthylamine-3,6,8-trisulfonic acid solution of 8g / L, the hydrotalcite precursor that adds 0.2g step a preparation after adding the hydrotalcite precursor of 0.2g step a with sodium hydroxide regulator solution pH value, in N 2 Stir under protection, react at 30°C for 48 hours, the product uses CO 2 Washing with water and centrifuging to obtain 1-naphthylamine-3,6,8-trisulfonic acid intercalated hydrotalcite;

[0043] c. Take 1 g of 1-naphthylamine-3,6,8-trisulfonic acid intercalated hydrotalcite prepared in step b, dissolve it in 90 ml of ethanol solution and sonicate for 12 minutes, put the mixed solution in a high-speed centrifuge, and set the speed at 7500 rpm / min, centrifuged for 9 minutes, and got the upper colloidal solution;

[0044] d. Take 20ml of the upper colloidal solution obtained in step c and place it in the electrochemical deposition liquid pool. 2 The conductive gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com