Kiln body arched beam in high-temperature area of pushed slab kiln with nitrogen protection

A pusher kiln and high-temperature zone technology, which is applied in the field of kiln body arch beams, can solve the problems of lowering the production efficiency of pusher kiln protected by nitrogen atmosphere, complicated maintenance and renovation, and cumbersome masonry process, so as to achieve convenient masonry and maintenance and reduce Economical burden, strong combination fastness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

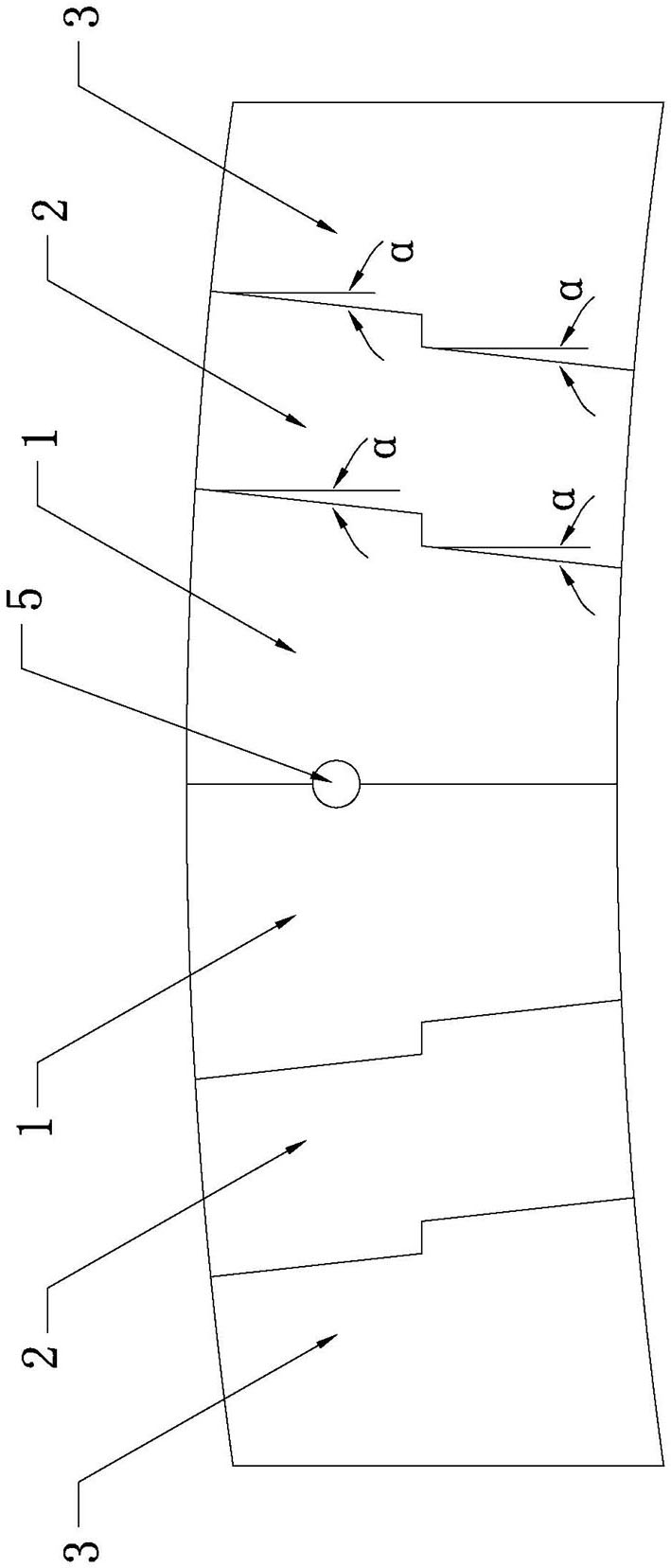

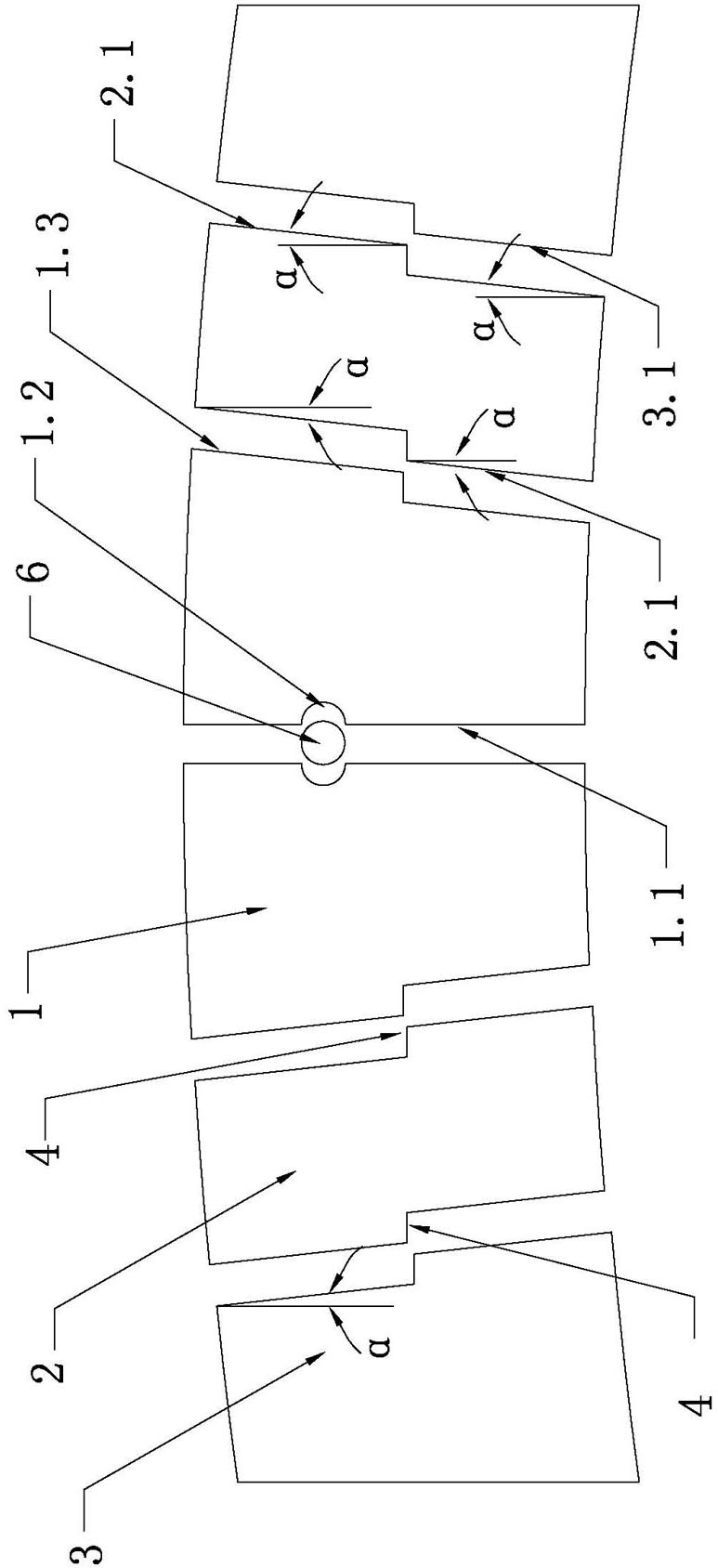

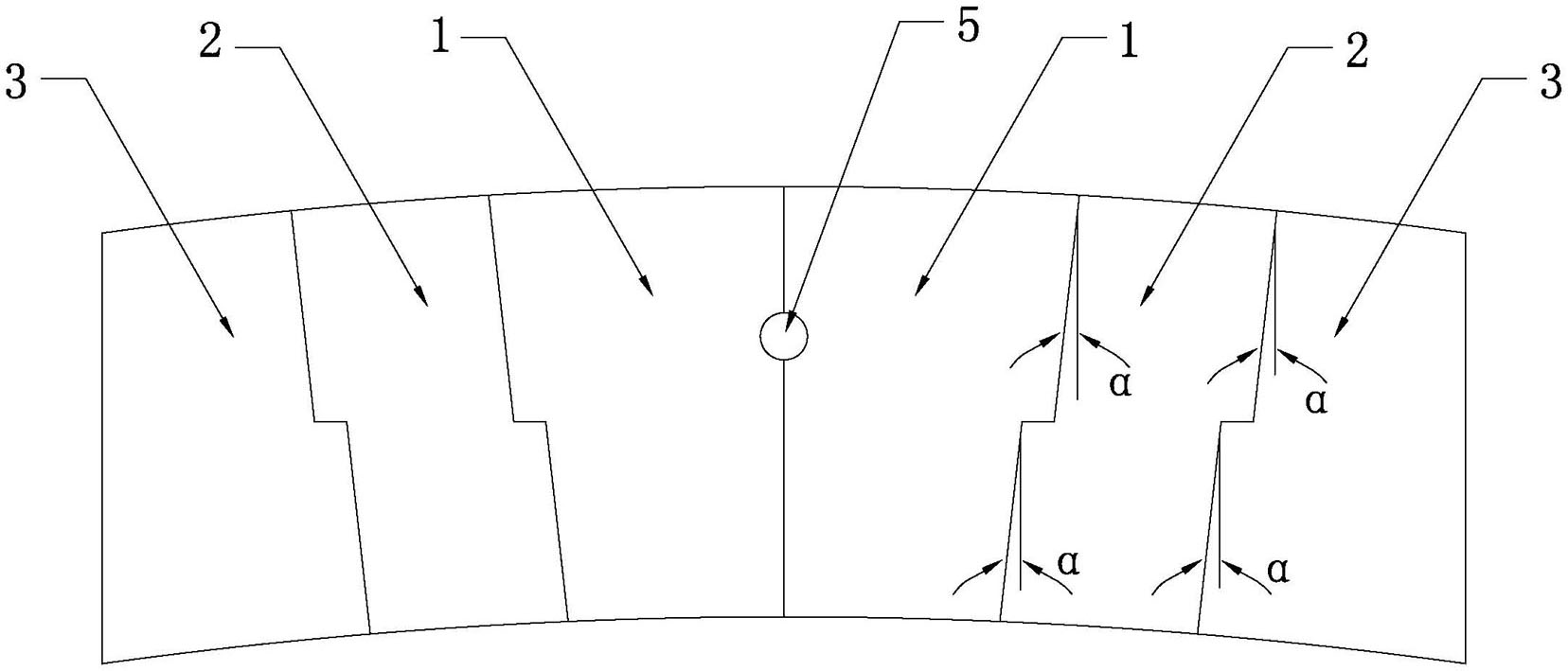

[0010] like figure 1 and figure 2 As shown, a nitrogen atmosphere protects the arch beam of the kiln body in the high temperature zone of the push plate kiln, which is characterized in that it includes two middle arch beam bricks 1, two inner arch beam bricks 2 and two outer arch beam bricks 3, the middle arch beam brick A connecting surface 1.1 of the brick 1 is provided with a semicircular groove 1.2, the other connecting surface 1.3 is an inclined surface, both connecting surfaces 2.1 of the inner arch beam brick 2 are inclined surfaces, and a connecting surface of the outer arch beam brick 3 3.1 is the inclined surface, the inclination angle α of the inclined surface of the middle arch beam brick 1, the inner arch beam brick 2 and the outer arch beam brick 3 is 5°, the middle arch beam brick 1, the inner arch beam brick 2 and the outer arch beam brick 3 There is a toothing step 4 corresponding to each other on the inclined surface; the middle arch beam brick 1, the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com