Polyethylene composition for rotational moulding and preparation method of polyethylene composition

A technology of polyethylene and composition, applied in the field of polyethylene composition for rotational molding, can solve the problems of poor use effect, reduced material toughness, environmental stress cracking resistance, etc., and achieves improved environmental stress cracking resistance, excellent Comprehensive performance, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

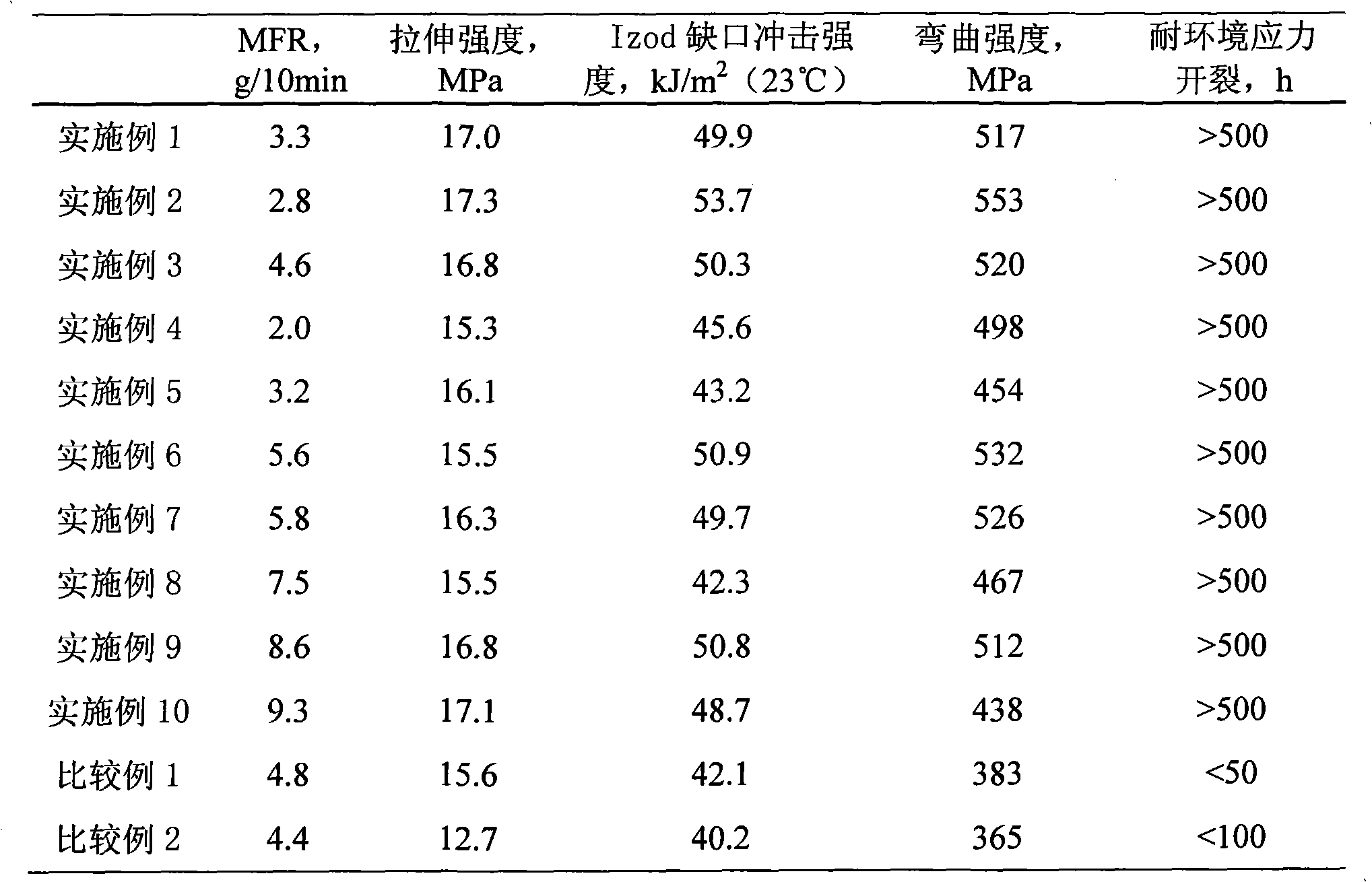

[0024] Add CNF (average diameter 190nm, length distribution range 1-60μm) and aminopropyltriethoxysilane coupling agent KH550 into a high-speed mixer successively, and mix at 80°C for 8 minutes to modify the surface of CNF, wherein The amount of surface modifier used is 0.5% by weight of CNF. 100 parts of LLDPE with a melt flow rate of about 5g / 10min, 0.2 parts of surface-modified CNF, antioxidant tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid] 0.05 part of pentaerythritol ester, 0.1 part of antioxidant tris(2,4-di-tert-butylphenyl) phosphite, light stabilizer poly-{[6-[(1,1,3,3-tetramethylbutyl Base)-imino]-1,3,5-triazine-2,4-diyl][2-(2,2,6,6-tetramethylpiperidinyl)-amino]-hexylene-[ Add 0.3 part of 4-(2,2,6,6-tetramethylpiperidinyl)-imino]} into the high-speed mixer, mix for 5 minutes, and Extruded and granulated by a screw extruder to obtain a polyethylene composition for rotomolding, the mechanical properties of which are shown in Table 1.

Embodiment 2

[0026]Add CNF (average diameter of 200nm, length distribution range of 1-60μm) and bis(dioctyloxypyrophosphate)ethylene titanate coupling agent NDZ-311 into the high-speed mixer successively, and mix at 80°C for 9 Minutes, the surface modification of CNF was carried out, wherein the amount of surface modifier was 1% of the weight of CNF. 100 parts of LLDPE with a melt flow rate of about 5g / 10min, 0.5 parts of surface-modified CNF, antioxidant tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid] 0.05 part of pentaerythritol ester, antioxidant 1,3,5-tris(3,5-di-tert-butyl-4-hydroxybenzyl)-s-triazine-2,4,6-(1H,3H,5H)trione 0.1 part, 0.2 part of antioxidant bis(2,4-di-tert-butylphenyl) pentaerythritol diphosphite, 0.3 part of light stabilizer 2-hydroxy-4-n-octyloxybenzophenone, light stabilizer Add 0.2 parts of the polymer of succinic acid and 4-hydroxy-2,2,6,6-tetramethyl-1-piperidinol into a high-speed mixer, mix for 5 minutes, and then process at a normal processing t...

Embodiment 3

[0028] Add CNF (average diameter 210nm, length distribution range 1-60μm) and distearoyloxyisopropoxyaluminate coupling agent SG-Al821 into the high-speed mixer successively, mix at 80°C for 10 minutes, and CNF Surface modification is carried out, wherein the amount of surface modifier is 3% by weight of CNF. 100 parts of LLDPE with a melt flow rate of about 5g / 10min, 0.8 parts of surface-modified CNF, antioxidant 1,3,5-tris(4-tert-butyl-3-hydroxy-2,6-di Methylbenzyl)-1,3,5-triazine-2,4,6-(1H,3H,5H)trione 0.7 parts, light stabilizer 2-hydroxy-4-n-octyloxybenzophenone Add 0.5 parts and 0.4 parts of 2-(2'-hydroxy-5'-tert-octylphenyl)benzotriazole into a high-speed mixer, mix for 5 minutes, and then process at a normal processing temperature of 180-240°C The twin-screw extruder extruded and granulated to obtain a polyethylene composition for rotomolding, and its mechanical properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com