Isoolefine production method

A production method and technology for isoolefins, which are applied in the field of preparing isoolefins directly by cracking tertiary alkyl ethers, can solve problems such as large energy consumption, and achieve the effects of improving economic benefits, facilitating operation and separation, and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

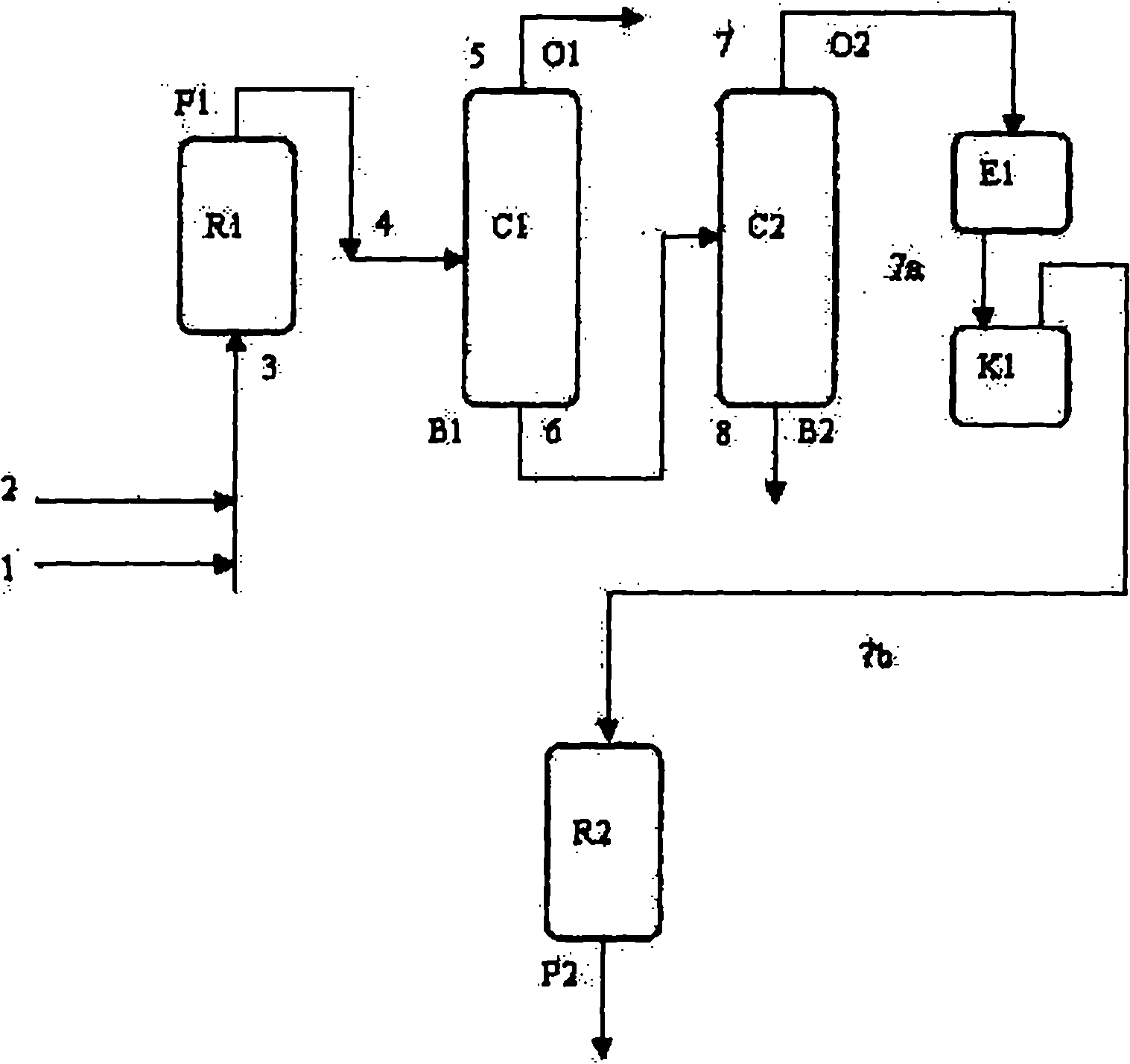

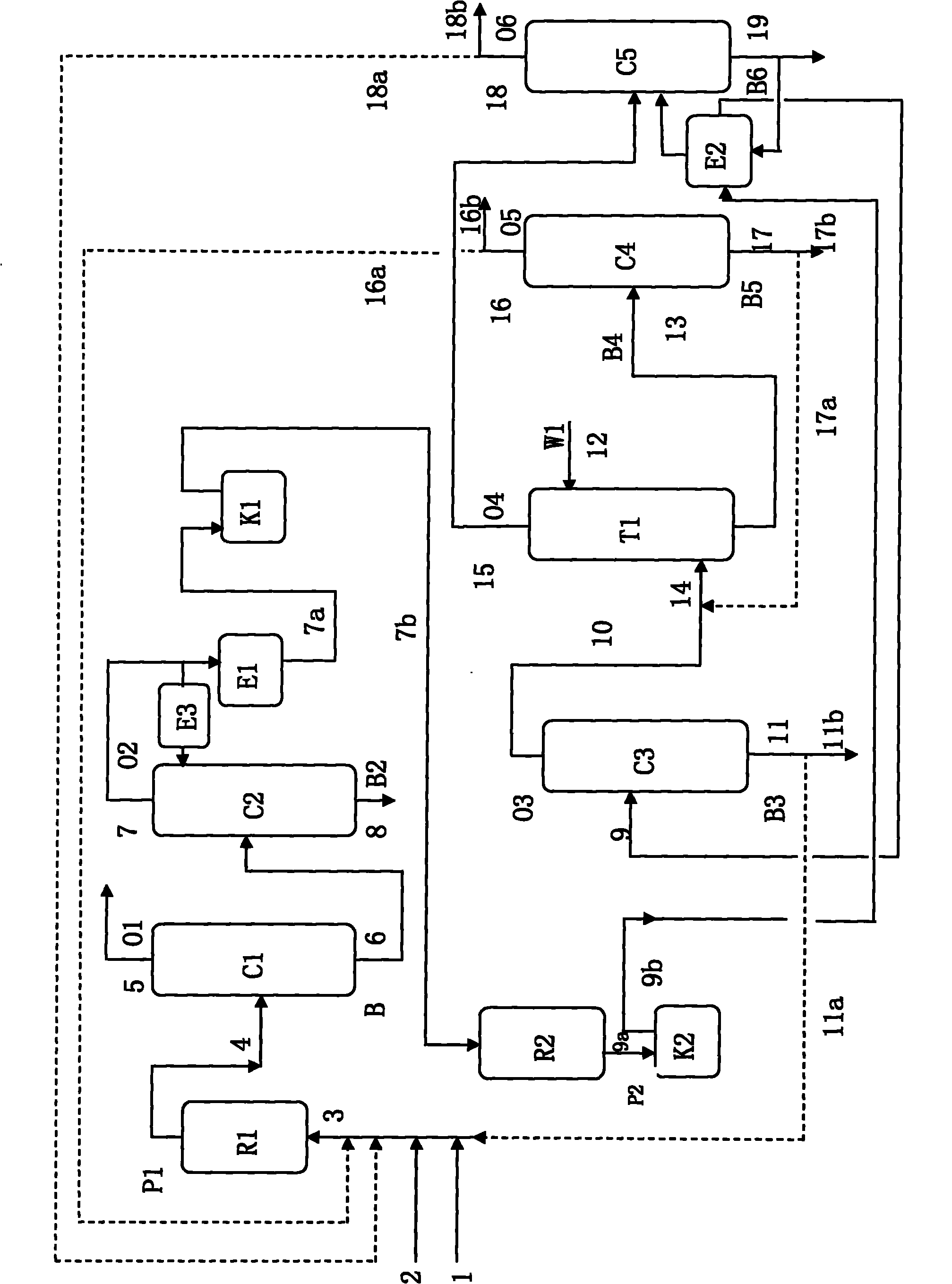

Method used

Image

Examples

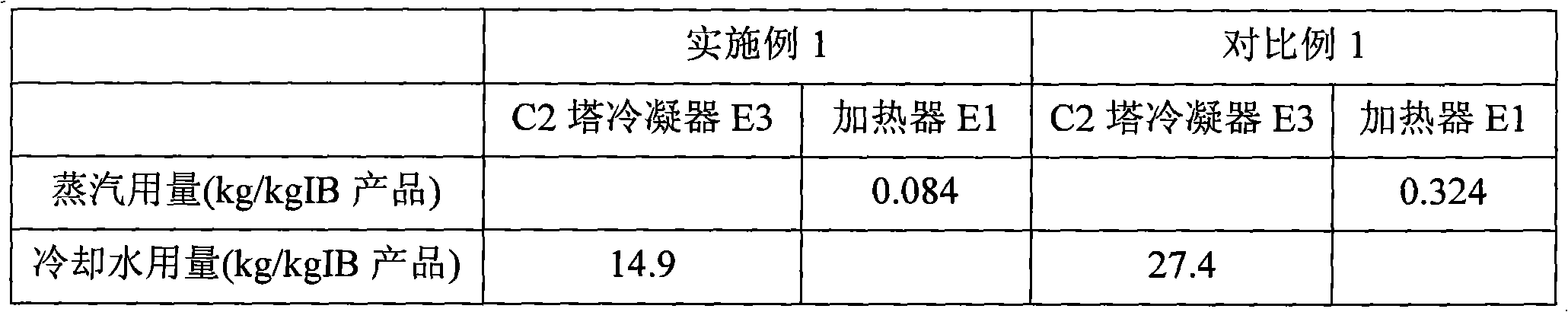

Embodiment 1

[0050] The raw material mixed C4 is the product of the ethylene cracking unit (the cracked C4 raw material after the removal of diene comes from the first chemical plant of Yanshan Branch of Sinopec, the same below), and the mixed C4 hydrocarbons and methanol containing isobutene pass through pipelines 1 and 2 respectively. and 3 enter the etherification reactor R1, the content of isobutene in the mixed carbon four hydrocarbons is about 20.1% (weight), the raw material amount entering the etherification reactor is 100kg / h, Amberlyst 15 solid is housed in the etherification reactor R1 Acid resin catalyst (produced by ROHM & HAAS), the reaction temperature of etherification reactor R1 is 60°C, the reaction pressure is 1.2MPa, and the space velocity of etherification reactor is 6hr -1 . The weight ratio of methanol and isobutene entering the etherification reactor was 0.6. The etherification product P1 enters the first fractionation tower C1 through the pipeline 4. The operating...

Embodiment 2

[0057] The mixed carbon four hydrocarbons containing isobutene and methyl alcohol enter etherification reactor R1 through pipeline 1, 2 and 3 respectively, and the content of isobutene in the mixed carbon four hydrocarbons is 20.1% (weight), and the raw material amount that enters etherification reactor is 100kg / h, Amberlyst 15 solid acid resin catalyst (produced by ROHM & HAAS) is installed in the etherification reactor R1, the reaction temperature of the etherification reactor R1 is 60°C, the reaction pressure is 1.2MPa, and the space velocity of the etherification reactor is 6hr -1 . The weight ratio of methanol and isobutene entering the etherification reactor was 0.6. The etherified product P1 enters the first fractionation tower C1 through the pipeline 4. The operating pressure of the first fractionation tower C1 is 0.9MPa. Send into the second fractionating tower C2 through pipeline 6, the operating pressure of the second fractionating tower C2 is 0.5MPa, and the theo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com