Pneumatic tire

A technology for pneumatic tires and tires, applied to the reinforcement layer of pneumatic tires, tire parts, tire tread/tread pattern, etc., which can solve the problems of inability to obtain ground contact area, deterioration of anti-slip performance, and easy occurrence of swaying , to achieve the effect of improving anti-yaw performance, improving icy road performance and reducing reaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

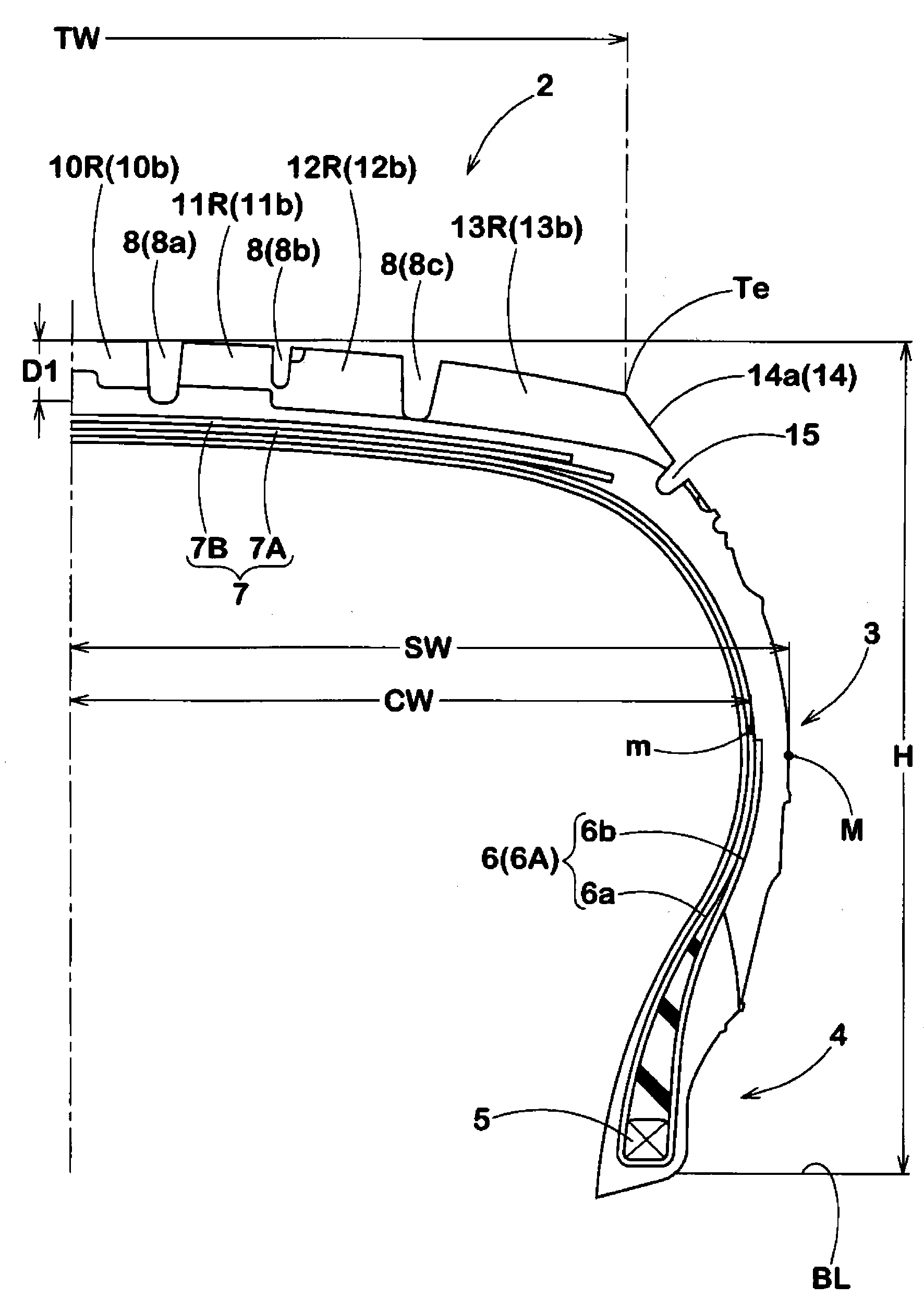

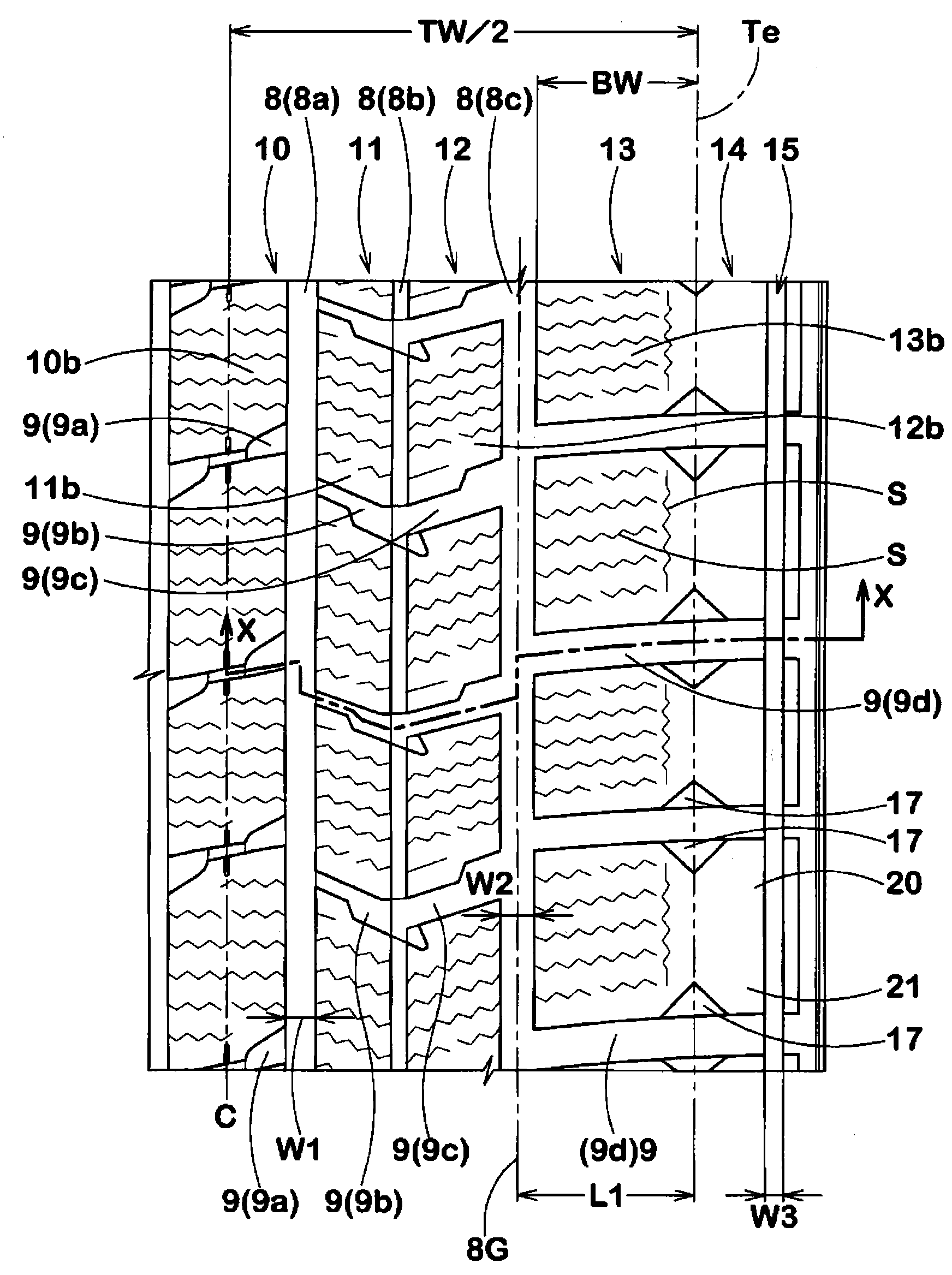

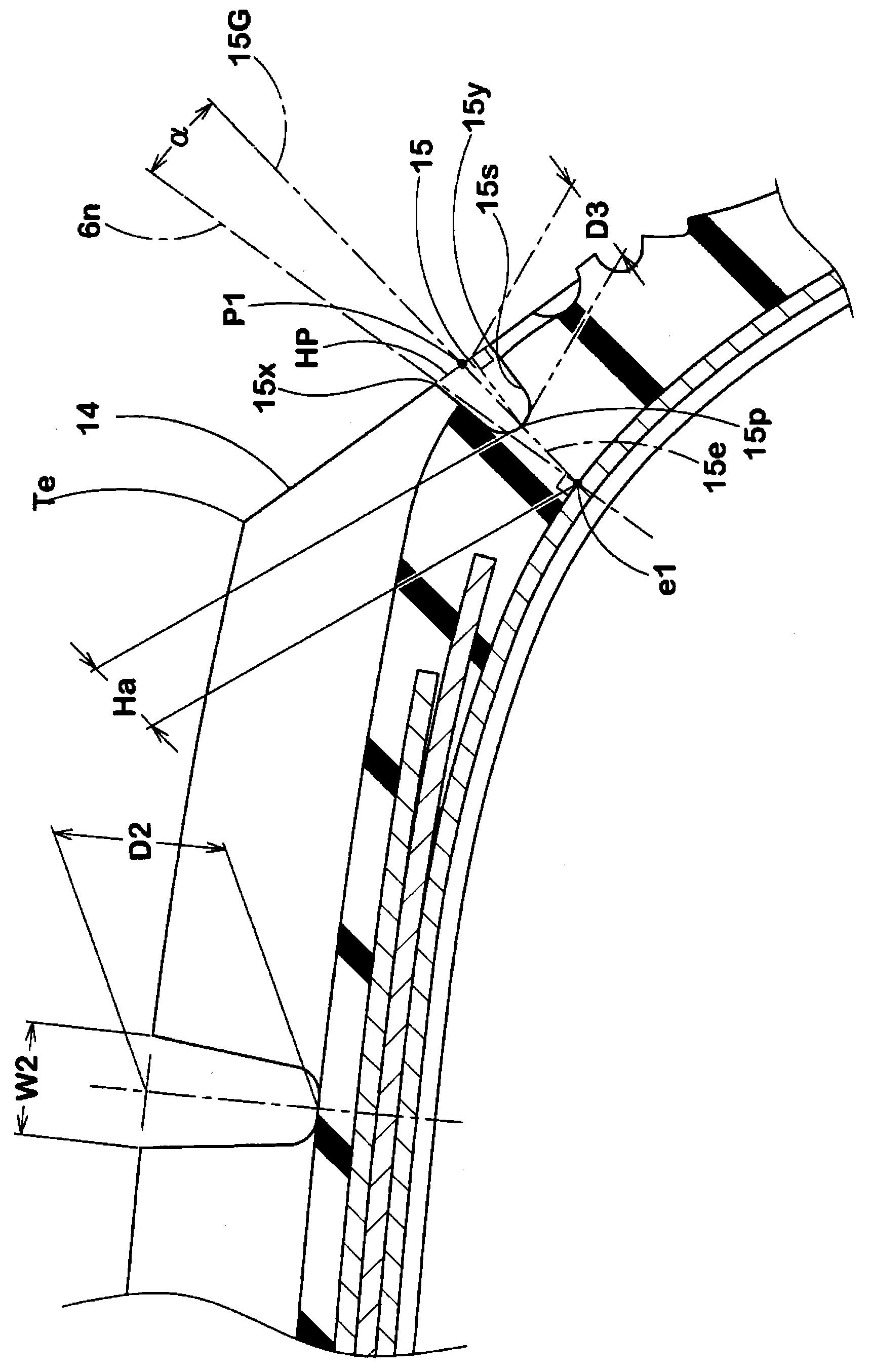

[0026] Hereinafter, an embodiment of the present invention will be described based on the drawings.

[0027] figure 1 Is a cross-sectional view showing the right half of the pneumatic tire 1 of this embodiment, figure 2 Is its expanded view. among them, figure 1 The cross-sectional view of shows a meridian section including the tire rotation axis in a normal state where it is mounted on a normal rim (not shown) and filled with normal internal pressure without load. Unless otherwise specified, the dimensions of each part of the tire are the values measured in the normal state.

[0028] The above-mentioned “regular rim” refers to the rim specified for each tire in the specification system including the specifications on which the tire is based. If it is JATMA, it is “standard rim”, if it is TRA, it is “Design Rim”. ETRTO is "Measuring Rim". In addition, the above-mentioned "regular internal pressure" refers to the air pressure specified for each tire in the specification syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com