Drawing mould special for metal manifolds

A collection tube and metal technology, which is applied to manufacturing tools, metal processing equipment, forming tools, etc., can solve the problems of large reduction rate of the wall thickness of the branch pipe at the extrusion deformation speed, and the dimensional accuracy of the branch pipe hole is difficult to control. Drawing efficiency, reduction of machining amount, elimination of different effects of vertical and horizontal rebound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

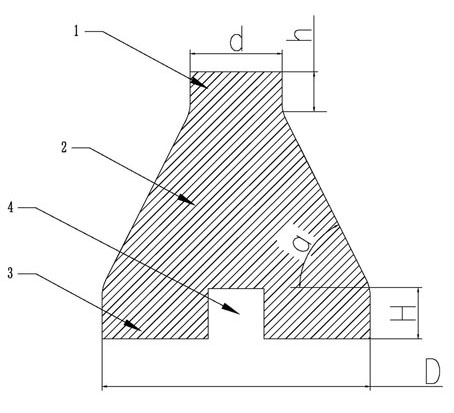

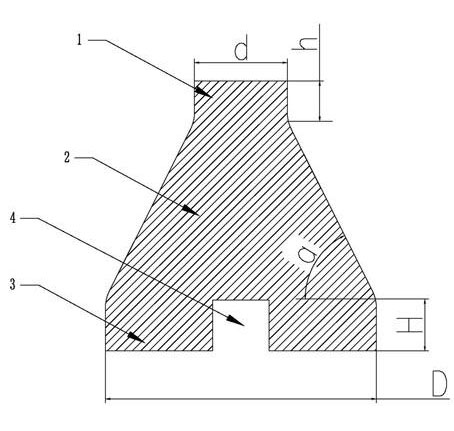

[0011] like figure 1 As shown, a special drawing die for a metal collection tube includes a drawing die, which is characterized in that the drawing die is an integrated drawing die composed of upper, middle and lower parts, and the upper The part 1 and the lower part 3 are cylinders, the middle part 2 of the one-piece drawing die is a cone; the angle a of the cone of the middle part 2 is 30 degrees, and there is a connecting groove 4 under the cylinder of the lower part 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com