Method for producing special sleeve opening

A production method and a special technology, applied in clothing, clothing, applications, etc., can solve problems such as difficulty in ensuring product quality, rough cuffs of finished garments, and not too firm cuffs, and achieve the effect of smooth appearance, avoiding damage, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the content of the invention, features and effects of the present invention, the following examples are given hereby, and in conjunction with the accompanying drawings, the present invention is described in detail as follows:

[0027] The manufacture method of special cuff of the present invention, comprises the steps:

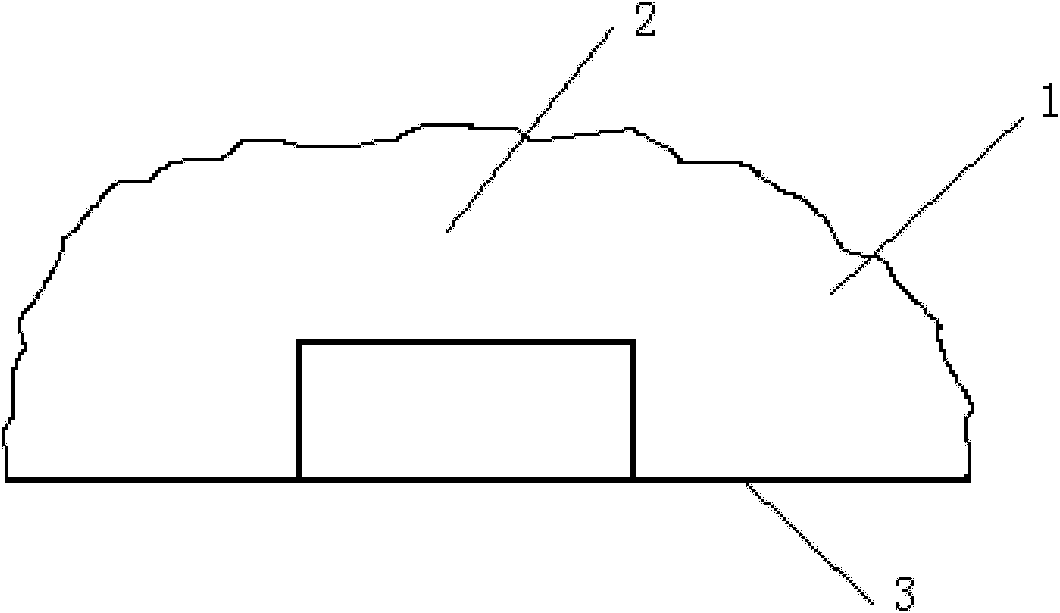

[0028] 1) if figure 1 As shown, mark the net line 2 on the reverse side of the cuff garment part 1 according to the net board;

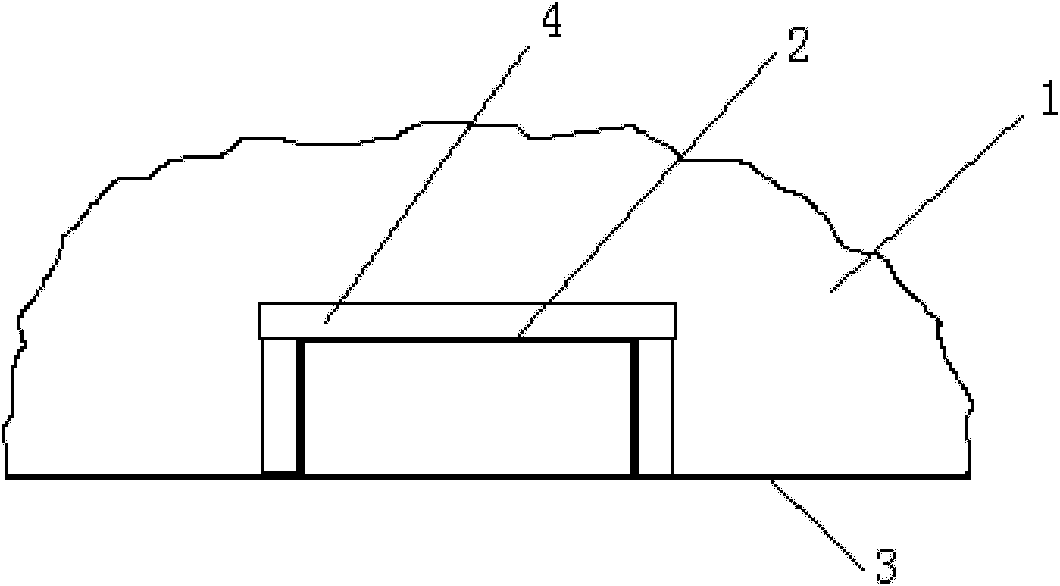

[0029] 2) if figure 2 As shown, there is a spinning strip 4 on the outer side of the clean line 2;

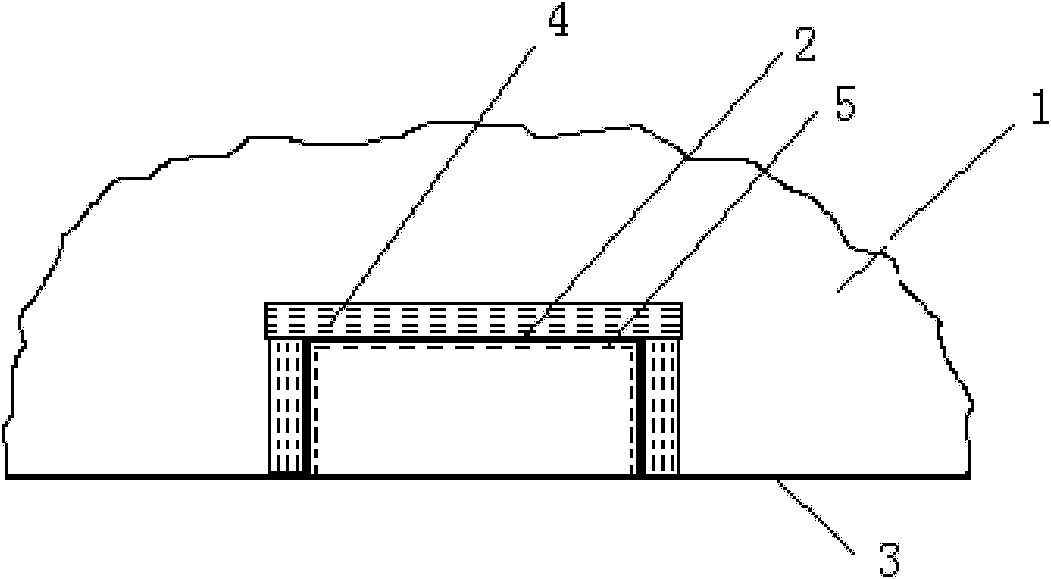

[0030] 3) if image 3 As shown, the lining of the cuffs and the face cloth are sewed with a lockstitch machine along the spun insert 4 with a lockstitch machine, so that the hidden line 5 of the cuffs is in the shape of "∏";

[0031] Said sewing includes sewing the spun inserts 4 on the cuff parts with a lockstitch machine.

[0032] 4) Make a cut 7 at the corner of the "∏" hidden line 5 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com