Gradient cracking method for researching compound cracking process

A compound and compound technology, applied in the field of compound analysis, can solve problems such as complex products, unfavorable compound cracking process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] Example 1 Cracking of chlorogenic acid

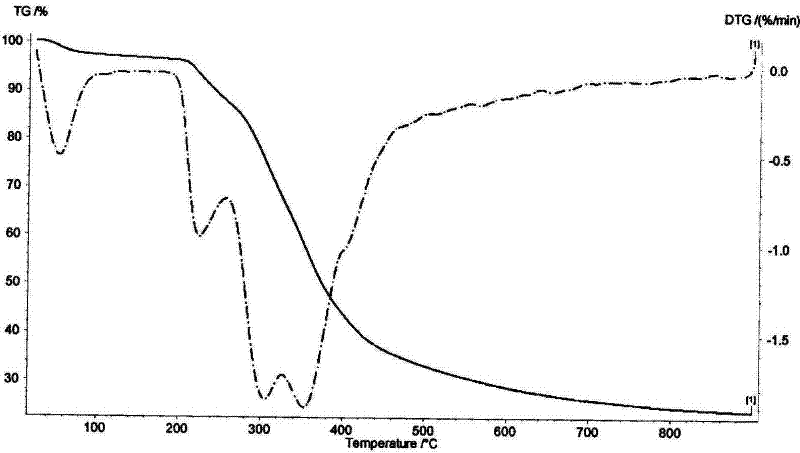

[0022] Weigh about 10 mg of chlorogenic acid (purity >99%) into an alumina crucible, and raise the temperature from 30 °C to 900 °C at a heating rate of 5 °C / min under a nitrogen flow rate of 40 mL / min. The thermogravimetric analyzer records the weight loss curve of chlorogenic acid, and after a differential, the differential thermogravimetric curve is obtained. like figure 1 Shown:

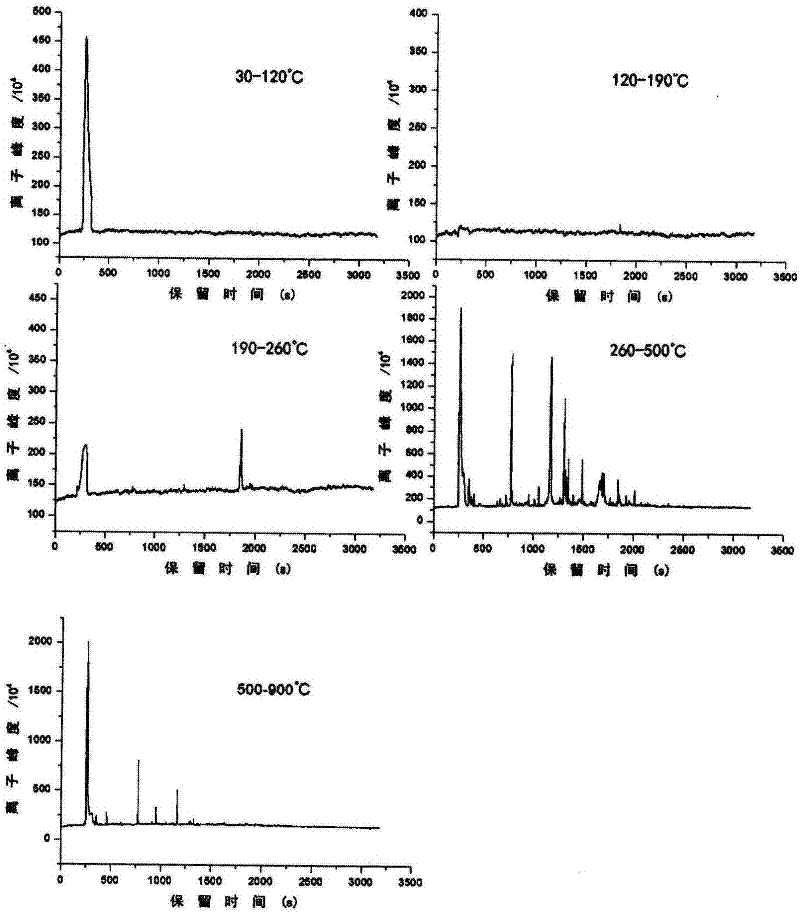

[0023] It can be seen from the weight loss curve and differential thermogravimetric curve that the cracking of chlorogenic acid can be divided into five stages. The first stage is 30-120°C; the second stage is 120-190°C; the third stage is 190-260°C; the fourth stage is 260-500°C; the fifth stage is 500-900°C.

[0024] Weigh about 2 mg of sample into the quartz sample tube of the pyrolysis device, and perform isothermal cracking at 120, 190, 260, 500, and 900° C. for 20 minutes at each temperature point. Here, choosing the highest temperature ...

example 2

[0029] Example 2 Cracking of quinic acid

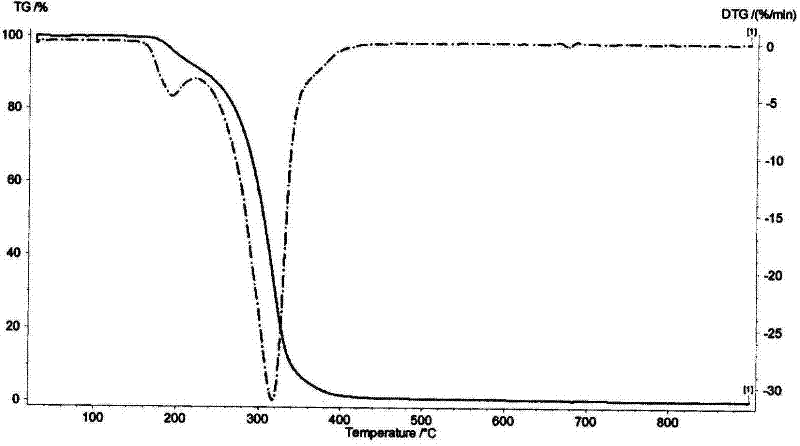

[0030] Weigh about 10 mg of quinic acid (purity >99%) into an alumina crucible, and raise the temperature from 30 °C to 900 °C at a heating rate of 5 °C / min under a nitrogen flow rate of 40 mL / min. The thermogravimetric analyzer records the weight loss curve of chlorogenic acid, and after a differential, the differential thermogravimetric curve is obtained. like image 3 Shown:

[0031] It can be seen from the weight loss curve and differential thermogravimetric curve that the cracking of chlorogenic acid can be divided into four stages. The first stage is 30-150°C; the second stage is 150-220°C; the third stage is 220-400°C; the fourth stage is 400-900°C.

[0032] Weigh about 2 mg of sample into the quartz sample tube of the pyrolysis device, and perform isothermal cracking at 150, 220, 400, and 900° C. for 20 minutes at each temperature point. The cleavage products of each stage were separated and analyzed by GC / MS.

[0033] ...

example 3

[0037] Cracking of example 3 rutin

[0038] Weigh about 10 mg of rutin (purity >98%) into an alumina crucible, and raise the temperature from 30 °C to 900 °C at a heating rate of 5 °C / min under a nitrogen flow rate of 40 mL / min. The thermogravimetric analyzer records the weight loss curve of chlorogenic acid, and after a differential, the differential thermogravimetric curve is obtained. like Figure 5 Shown:

[0039] It can be seen from the weight loss curve and differential thermogravimetric curve that the cracking of rutin can be divided into four stages. The first stage is 30-180°C; the second stage is 180-366°C; the third stage is 366-600°C; the fourth stage is 600-900°C.

[0040] Weigh about 2 mg of sample into the quartz sample tube of the pyrolysis device, and perform isothermal cracking at 180, 366, 600, and 900° C. for 20 minutes at each temperature point. The cleavage products of each stage were separated and analyzed by GC / MS.

[0041] GC / MS conditions:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com