Method for manufacturing water retaining/absorption dam for intercepting fire fighting wastewater

A production method and water absorption technology, which are applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve the problems of intercepting fire-fighting wastewater, hidden dangers, and sharp reduction in water absorption, so as to block the impact of fire-fighting wastewater, prevent potential safety hazards, and respond to emergency situations. Ability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

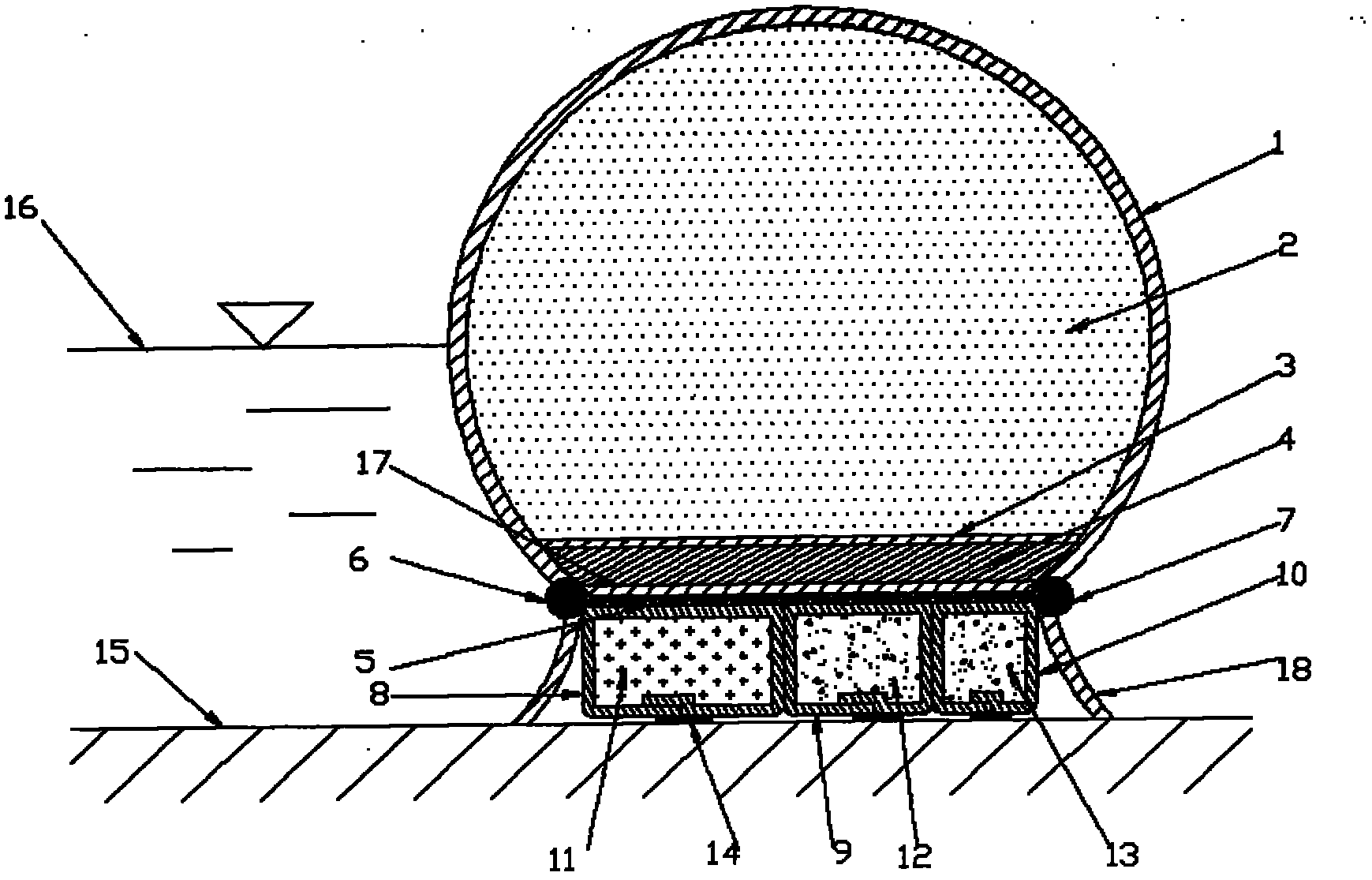

[0061] Prepare starch solution with 120g of pullulan and 1440g of water, gelatinize at 100°C for 2min, add 0.18g of potassium persulfate and acrylic acid monomer, the monomer is neutralized by 25% sodium hydroxide solution , neutralization degree 80%, stirring reaction for 30min, while cooling to 60°C with nitrogen gas, then adding 0.003g of N,N'-methylenebisacrylamide, gradually stopping stirring, and carrying out crosslinking reaction in a constant temperature water bath at 65°C 2 ~3h, drying and grinding to obtain powdery viscous water-absorbing resin (11).

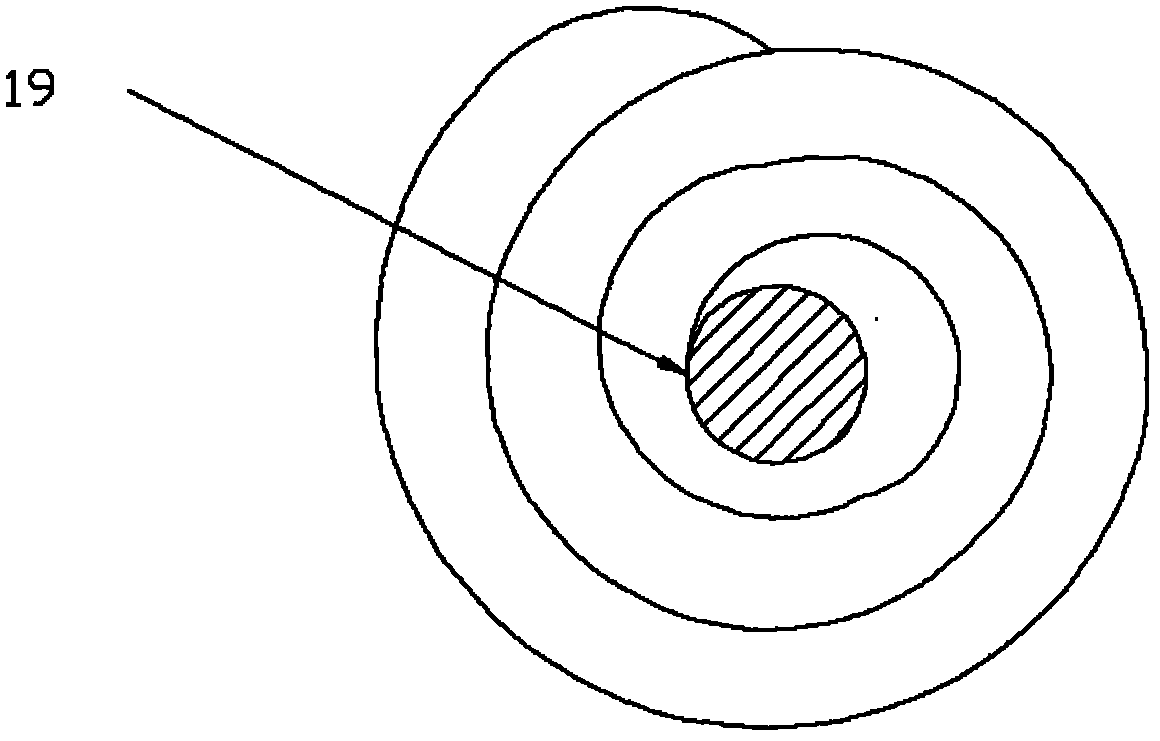

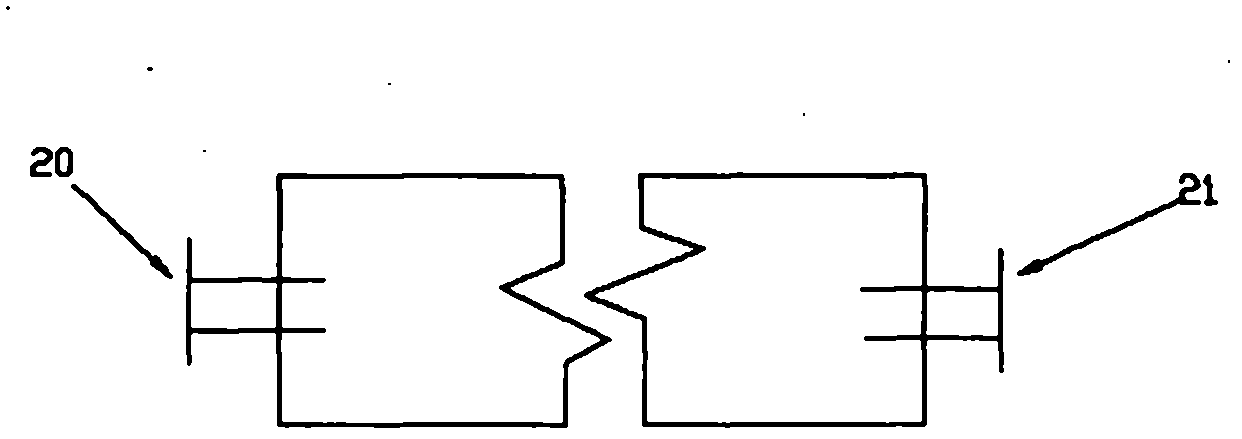

[0062] The water-retaining and absorbing dam comprises an air bag (1) made of waterproof material, a compartment (3), a belt (8), a belt (9) and a belt (10) made of water-absorbing material; the upper and lower parts The interface (5) is connected by sewing, and the gap around the upper and lower parts is sealed with polyurethane glue after the upper and lower parts are connected. Put the bar-shaped support (4) in the...

Embodiment 2

[0064] Prepare starch solution with 120g of amylopectin and 1440g of water, gelatinize at 130°C for 1.8min, add 0.18g of potassium persulfate and acrylic acid monomer, the monomer is passed through a sodium hydroxide solution with a mass fraction of 25%. And, with a neutralization degree of 80%, stir the reaction for 30 minutes, and cool to 60°C with nitrogen gas at the same time, then add 0.003g of N,N'-methylenebisacrylamide, gradually stop stirring, and carry out cross-linking reaction in a constant temperature water bath at 65°C After 2-3 hours, dry and grind to obtain a powdery viscous water-absorbing resin (11).

[0065] The water-retaining and absorbing dam comprises an air bag (1) made of waterproof material, a compartment (3), a belt (8), a belt (9) and a belt (10) made of water-absorbing material; the upper and lower parts The interface (5) is connected by sewing technology, and the gaps around the upper and lower parts are sealed with sealant after the upper and low...

Embodiment 3

[0067] Prepare starch solution with 120g of amylopectin and 1440g of water, gelatinize at 150°C for 1.5min, add 0.18g of potassium persulfate and acrylic acid monomer, the monomer is passed through a sodium hydroxide solution with a mass fraction of 25%. And, with a neutralization degree of 80%, stir the reaction for 30 minutes, and cool to 60°C with nitrogen gas at the same time, then add 0.003g of N,N'-methylenebisacrylamide, gradually stop stirring, and carry out cross-linking reaction in a constant temperature water bath at 65°C After 2-3 hours, dry and grind to obtain a powdery viscous water-absorbing resin (11).

[0068] The water-retaining and absorbing dam comprises an air bag (1) made of waterproof material, a compartment (3), a belt (8), a belt (9) and a belt (10) made of water-absorbing material; the upper and lower parts The interface (5) is connected by sewing technology, and the gaps around the upper and lower parts are sealed with sealant after the upper and low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com