Molybdate additive and polycrystalline silicon or monocrystalline silicon cutting fluid containing same

A silicon cutting fluid and additive technology, applied in additives, petroleum industry, lubricating composition, etc., can solve the problems of complex manufacturing process, unfriendly environment, high cost, etc., achieve good cutting effect, avoid chemical bonding adsorption, and stable quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

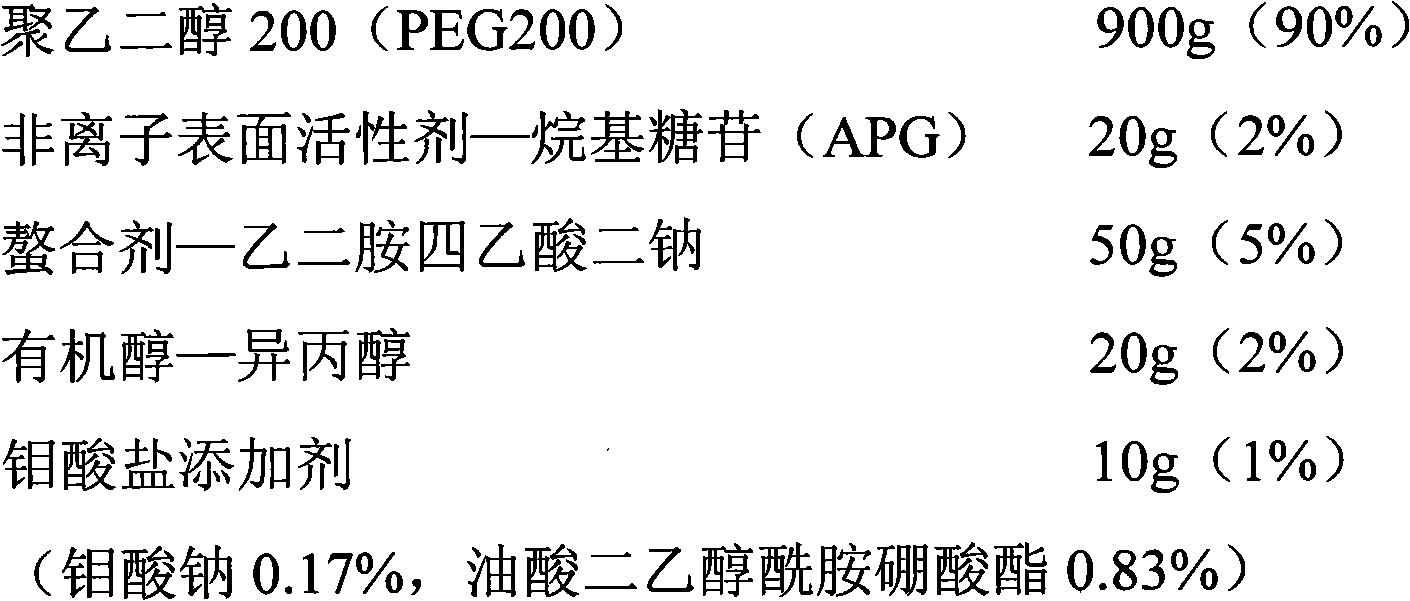

[0032] 1. The formula of the molybdate additive is sodium molybdate: oleic acid diethanolamide borate=1:5.

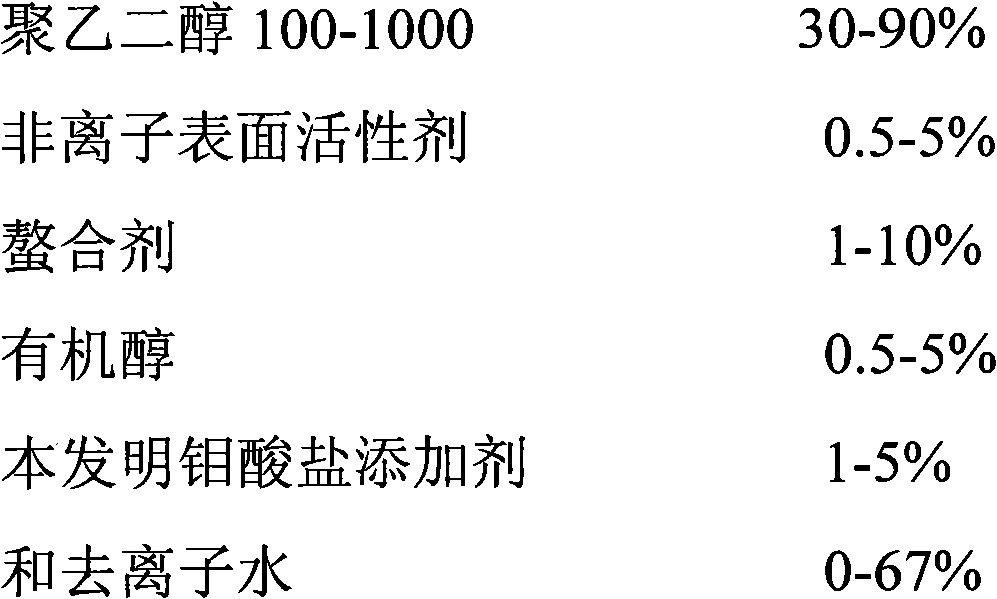

[0033] 2. Multi (single) silicon cutting fluid formula (1000g):

[0034]

[0035] 3. Preparation of multi-(single) crystal silicon cutting fluid:

[0036] Slowly add the alkyl glucoside, isopropanol, and molybdate additives in the above formula to polyethylene glycol 200 under continuous stirring, and then slowly add disodium edetate after the solution is clarified, and stir until uniform Instantly.

[0037] The product is mixed with the abrasive material (silicon carbide sand) at a ratio of 1:0.92, the suspension rate of the mortar within 48 hours of the product is 84.2%, and the recycling rate of the effective components of the cutting fluid is 93.5%. The product has good repeatability, can be used repeatedly for a long time, and the storage time can reach 36 months.

Embodiment 2

[0039] 1. The formula of the molybdate additive is sodium molybdate: oleic acid diethanolamide borate=1:10.

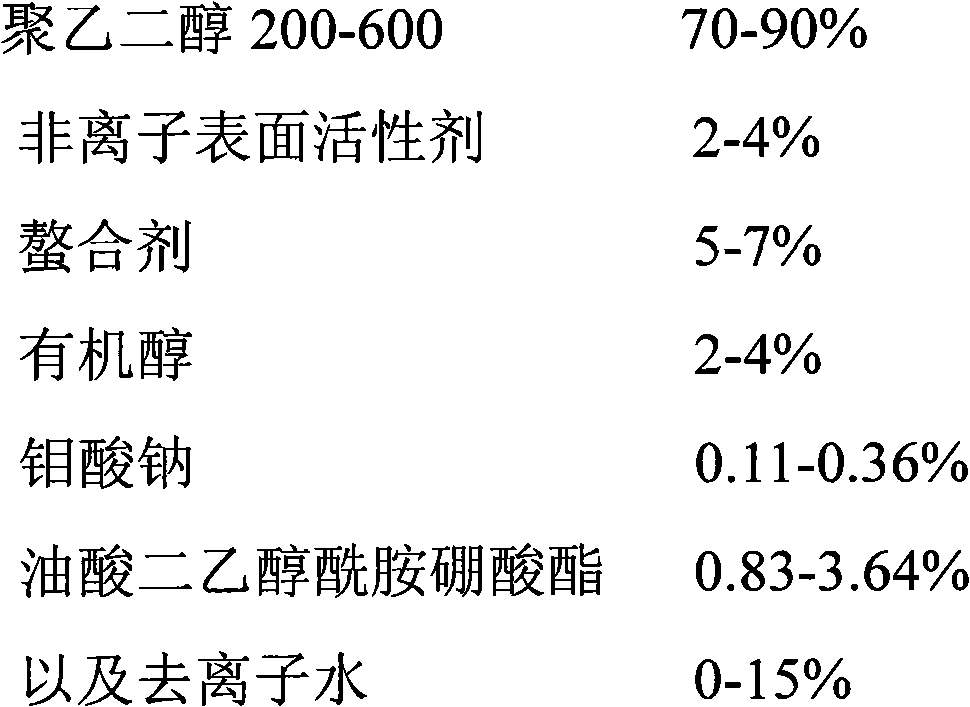

[0040] 2. Multi (single) silicon cutting fluid formula (1000g):

[0041]

[0042] 3. Preparation of multi-(single) crystal silicon cutting fluid:

[0043] Dissolve polyethylene glycol 200 with deionized water, and slowly add the alkyl glucoside, isopropanol, and molybdate additives in the above formula to the polyethylene glycol 200 under continuous stirring. Slowly add disodium ethylenediaminetetraacetate and stir until uniform.

[0044] The product is mixed with the abrasive material (silicon carbide sand) at a ratio of 1:0.92, the suspension rate of the mortar within 48 hours of the product is 83.5%, and the recycling rate of the effective components of the cutting fluid is 93.1%. The product has good repeatability, can be used repeatedly for a long time, and the storage time can reach 36 months.

Embodiment 3

[0046] 1. The formula of the molybdate additive is sodium molybdate: oleic acid diethanolamide borate=1:5.

[0047] 2. Multi (single) silicon cutting fluid formula (1000g):

[0048]

[0049] 3. Preparation of multi-(single) crystal silicon cutting fluid:

[0050] Heat polyethylene glycol 600 in a water bath to about 40°C, keep stirring continuously at this temperature, and slowly add the alkyl glucoside, isopropanol, alkyl glycoside, and molybdate additives in the above formula one by one until the solution After clarification, slowly add disodium ethylenediamine tetraacetate and stir until uniform.

[0051] When this product is mixed with abrasive material (silicon carbide sand) at a ratio of 1:0.92, the suspension rate of the mortar within 48 hours of the product is 84%, and the recycling rate of the effective components of the cutting fluid is 93.7%. The product has good repeatability, can be used repeatedly for a long time, and the storage time can reach 36 months.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com