Coal tar processing method

A treatment method, coal tar technology, applied in the treatment of hydrogen-generating compounds, etc., can solve the problems of incomplete utilization of coal tar, fast coking of the catalyst, and influence on the operation cycle, so as to improve the fusion effect and reaction effect, and improve the reaction effect , the effect of effective processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

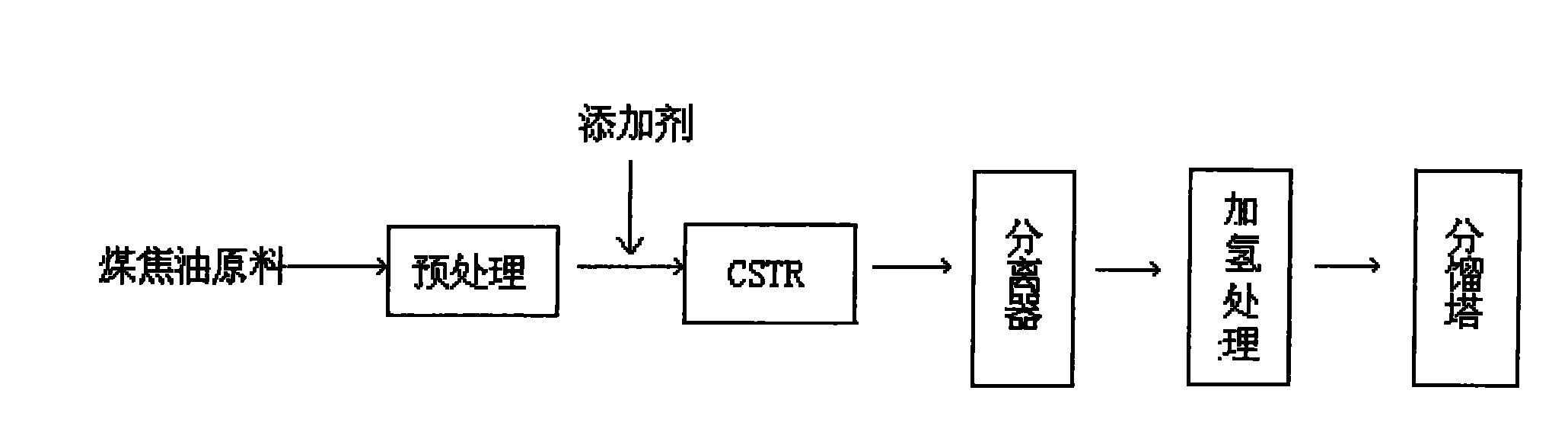

Method used

Image

Examples

Embodiment -1

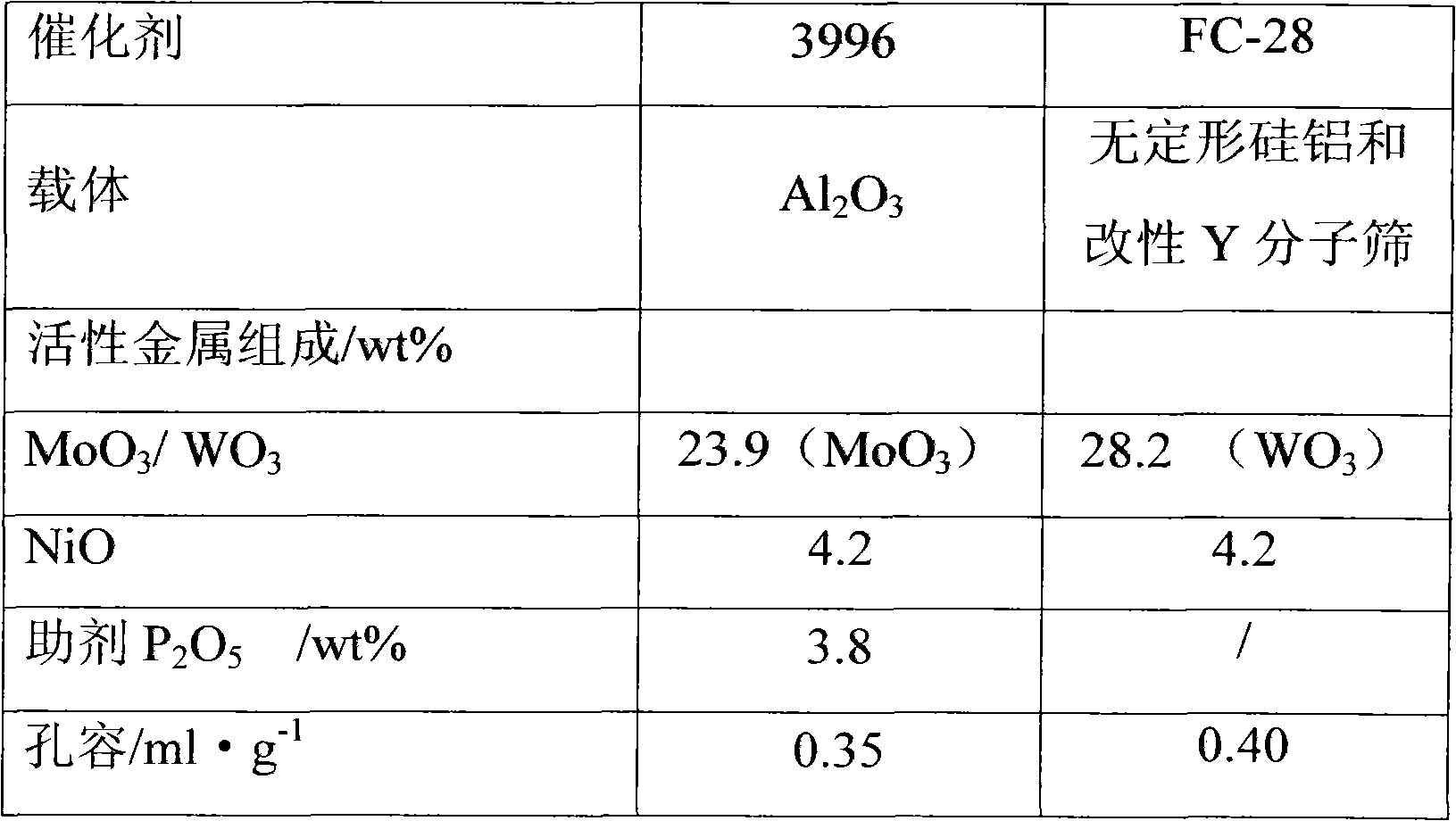

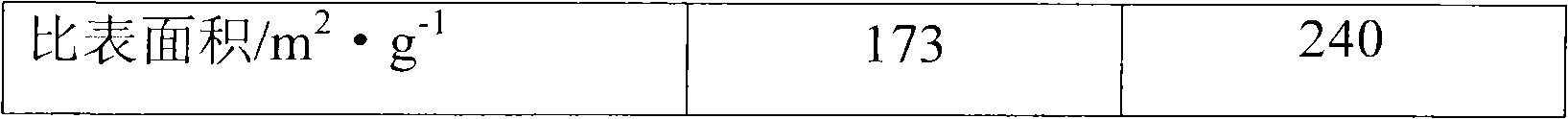

[0022] Coal tar and tetralin are added to the static mixer, (keep excess tetralin, the weight ratio of coal tar and tetralin to oil agent ratio is 1: 6), and then after the material is heated, it enters the CSTR (continuous stirred tank reactor ), pressurize, heat up and start stirring at a speed of 800 rpm, pressurize to 20MPa, heat up to 400°C, and the reaction time is 3h. The reacted product enters the separator after being filtered, and the gas phase and liquid phase are separated. The solid impurities separated by filtration can be burned or used as the raw material of needle coke, and the liquid phase is subjected to hydroprocessing and fractionation operations. The hydrogenation treatment adopts the commercial hydrogenation treatment catalyst 3996 developed and produced by Fushun Petrochemical Research Institute. The hydrogenation treatment process conditions are: total pressure 16MPa, average reaction temperature 380℃, volume space velocity 0.4h -1 , The volume ratio o...

Embodiment -2

[0024] Coal tar is used as raw material, the steps are the same as in Example-1, the hydrogen-donating solvent is decahydronaphthalene, the weight ratio of coal tar and hydrogen-donating solvent is 1:2, the reaction pressure is 35MPa, the reaction temperature is 450°C, and the reaction time is 0.5h (CSTR is continuous feeding and discharging, and the reaction time is the average residence time of materials). The hydrogenation treatment adopts the commercial hydrogenation treatment catalyst 3996 developed and produced by Fushun Petrochemical Research Institute. The hydrogenation treatment process conditions are: total pressure 14MPa, average reaction temperature 390℃, volume space velocity 0.2h -1 , The volume ratio of hydrogen to oil is 1500:1. After being processed by the method of the present invention, the properties of the diesel oil obtained by the fractionation tower are shown in Table 3.

Embodiment -3

[0026] By the same method as in Example 2, water is added simultaneously, and the weight ratio of water and residual oil raw material is 1:1. The hydrogenation treatment adopts the commercial hydrogenation treatment catalyst 3996 and FC-28 developed and produced by Fushun Petrochemical Research Institute in a volume ratio of 2:1. The reaction material first passes through the 3996 catalyst and then passes through the FC-29 catalyst. : Total pressure 16MPa, average reaction temperature 385℃, total volume space velocity 0.5h -1 , The volume ratio of hydrogen to oil is 2000:1. The properties of the diesel obtained from the anti-fractionation tower are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com