Solvothermal controllable method for preparing ZnSe and ZnTe nano materials

A nanomaterial and solvothermal technology, applied in nanotechnology, binary selenium/tellurium compounds, etc., can solve the problems that have not yet been seen, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

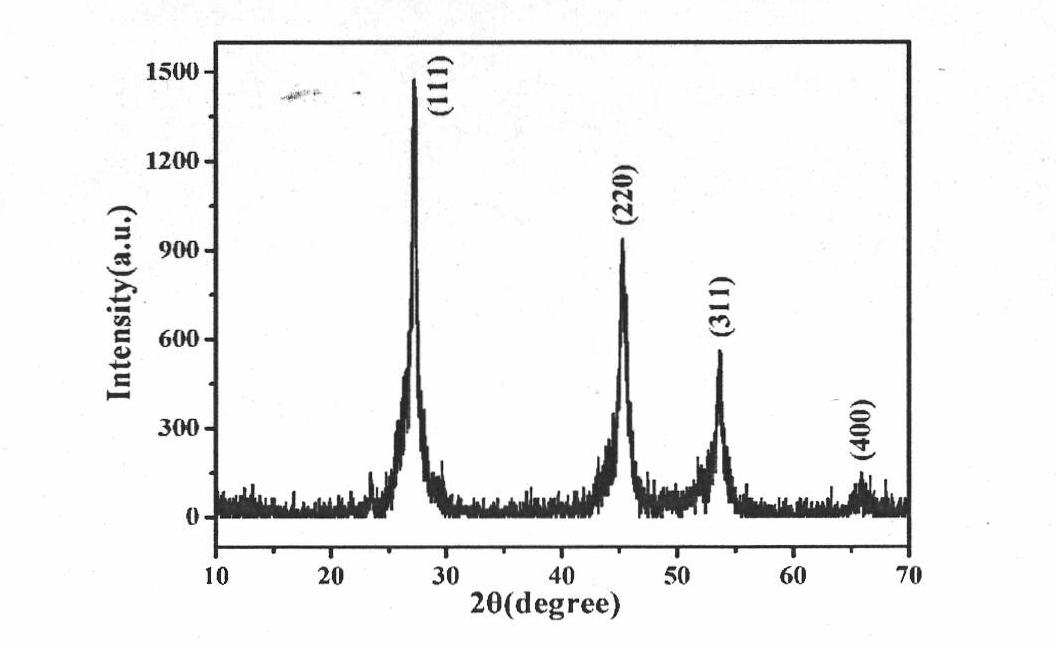

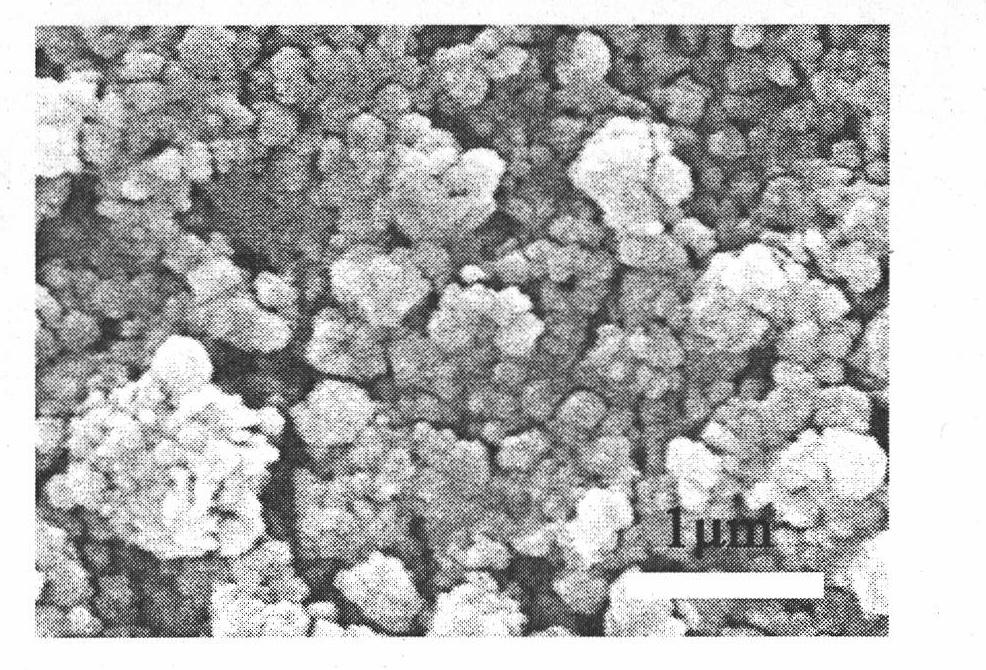

[0019] 1 mmol analytically pure sodium selenite (Na 2 SeO 3 ·5H 2 O) put into the polytetrafluoroethylene lining, add ethanolamine solvent to make the solution volume account for 80% of the total volume of the polytetrafluoroethylene lining. Magnetically stirred for several minutes, then added 2mmol of analytically pure zinc acetate (Zn(CH 3 COO) 2 2H 2 0), continue magnetic stirring until evenly sealed reaction kettle, placed in 200 ℃ oven reaction 24 hours. Naturally cooled to room temperature, the cooled product was collected, washed repeatedly with deionized water and absolute ethanol, and dried in vacuum at 60°C to obtain a yellowish-brown product. Such as figure 1 As shown, the XRD results show that the product is ZnSe with a cubic sphalerite structure; the SEM results show that the product is composed of nanoparticles with a diameter of about 100 nm, such as figure 2 .

Embodiment 2

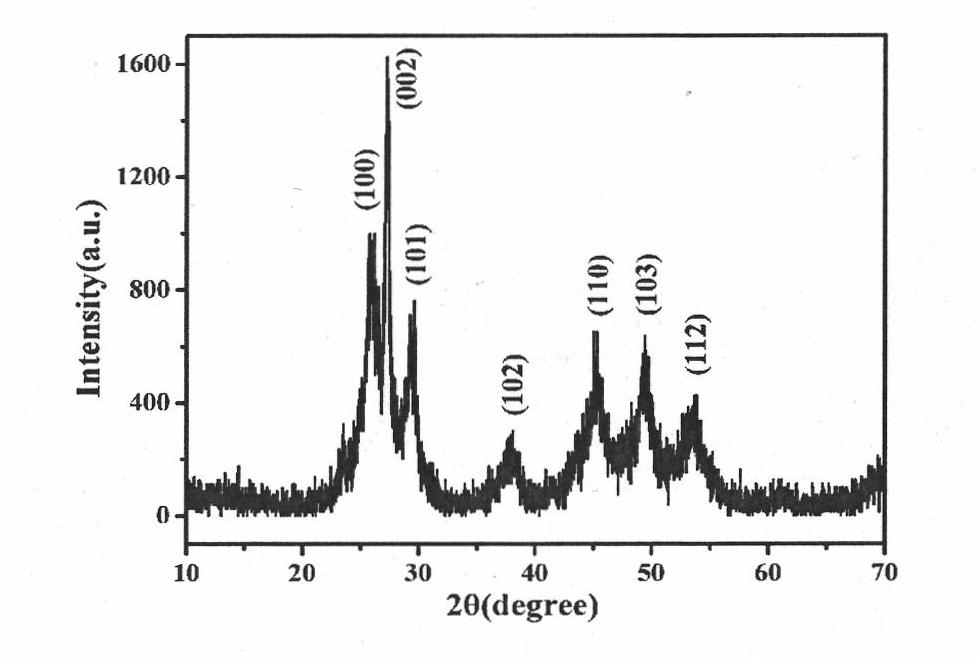

[0021] Put 1 mmol of analytically pure selenium powder (Se) into the polytetrafluoroethylene lining, and add ethanolamine solvent so that the volume of the solution accounts for 80% of the total volume of the polytetrafluoroethylene lining. Magnetically stirred for several minutes, then added 2mmol of analytically pure zinc acetate (Zn(CH 3 COO) 2 2H 2 0), continue magnetic stirring until evenly sealed reaction kettle, placed in 200 ℃ oven reaction 24 hours. Naturally cooled to room temperature, the cooled product was collected, washed repeatedly with deionized water and absolute ethanol, and dried in vacuum at 60°C to obtain a yellowish-brown product. XRD results show that the product is ZnSe with hexagonal wurtzite structure, such as image 3 ; SEM results show that the product is composed of nanosheets with a thickness of about 100 nm, such as Figure 4 shown.

Embodiment 3

[0023] 1 mmol analytically pure sodium tellurite (Na 2 TeO 3 ) into the polytetrafluoroethylene lining, adding ethanolamine solvent to make the solution volume account for 80% of the total volume of the polytetrafluoroethylene lining. Magnetically stirred for several minutes, then added 2mmol of analytically pure zinc acetate (Zn(CH 3 COO) 2 2H 2 0), continue magnetic stirring until evenly sealed reaction kettle, placed in 200 ℃ oven reaction 24 hours. Naturally cooled to room temperature, the cooled product was collected, washed repeatedly with deionized water and absolute ethanol, and dried under vacuum at 60°C to obtain a black product. XRD results show that the product is ZnTe with cubic sphalerite structure, such as Figure 5 ; SEM results show that the product is composed of nanoparticle aggregates with a diameter of about 100 nm, such as Figure 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com