Electromagnetic stirring magnetic head of double-wire submerged arc welding machine

A submerged arc welding machine and electromagnetic stirring technology, applied in arc welding equipment, welding equipment, welding accessories, etc., can solve the problems that the magnetic induction intensity and distribution cannot be stirred, it is difficult to obtain the effect of electromagnetic stirring, and the volume of the stirring head is large, etc., to achieve welding Suture tissue improvement, impact reduction, and volume reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

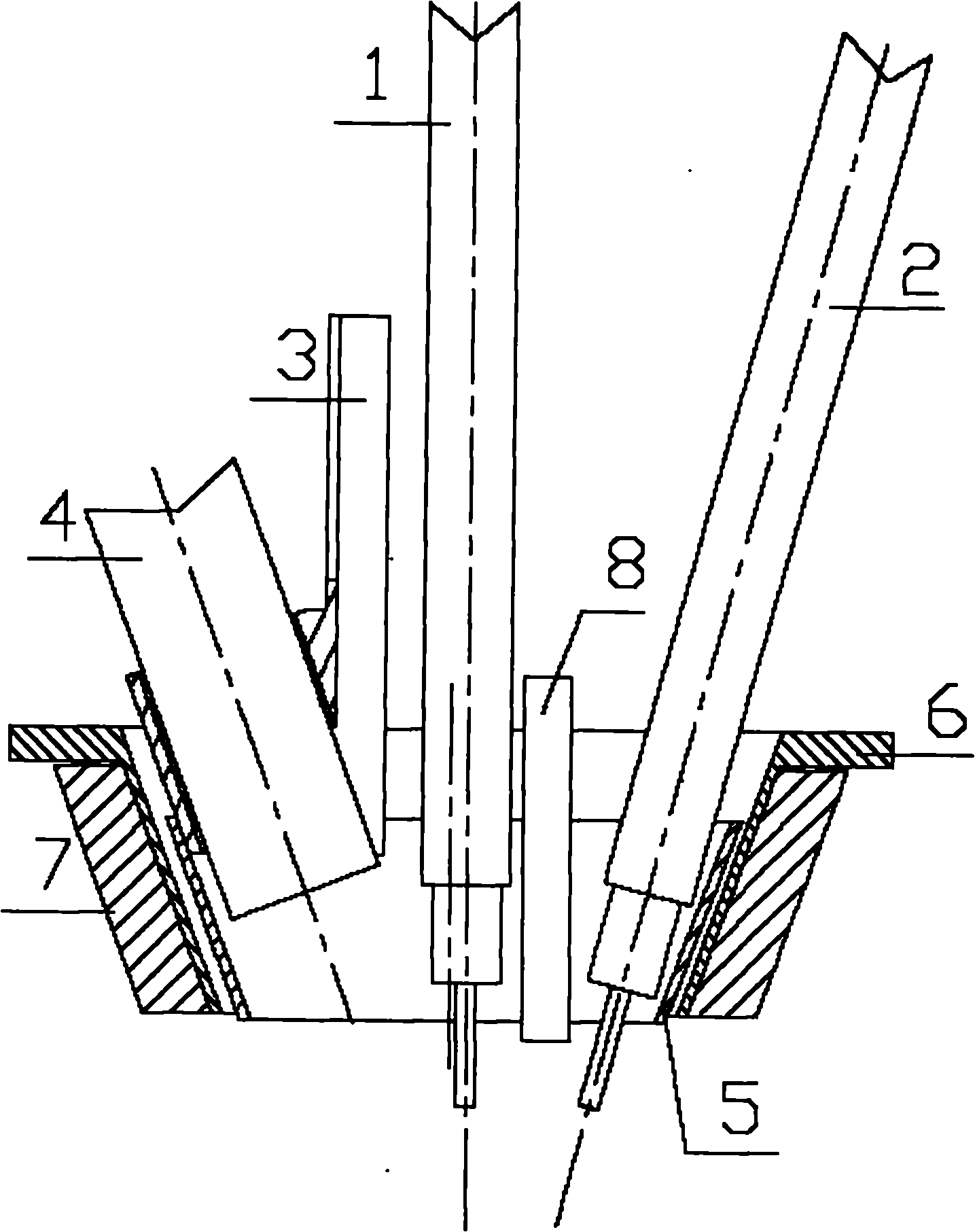

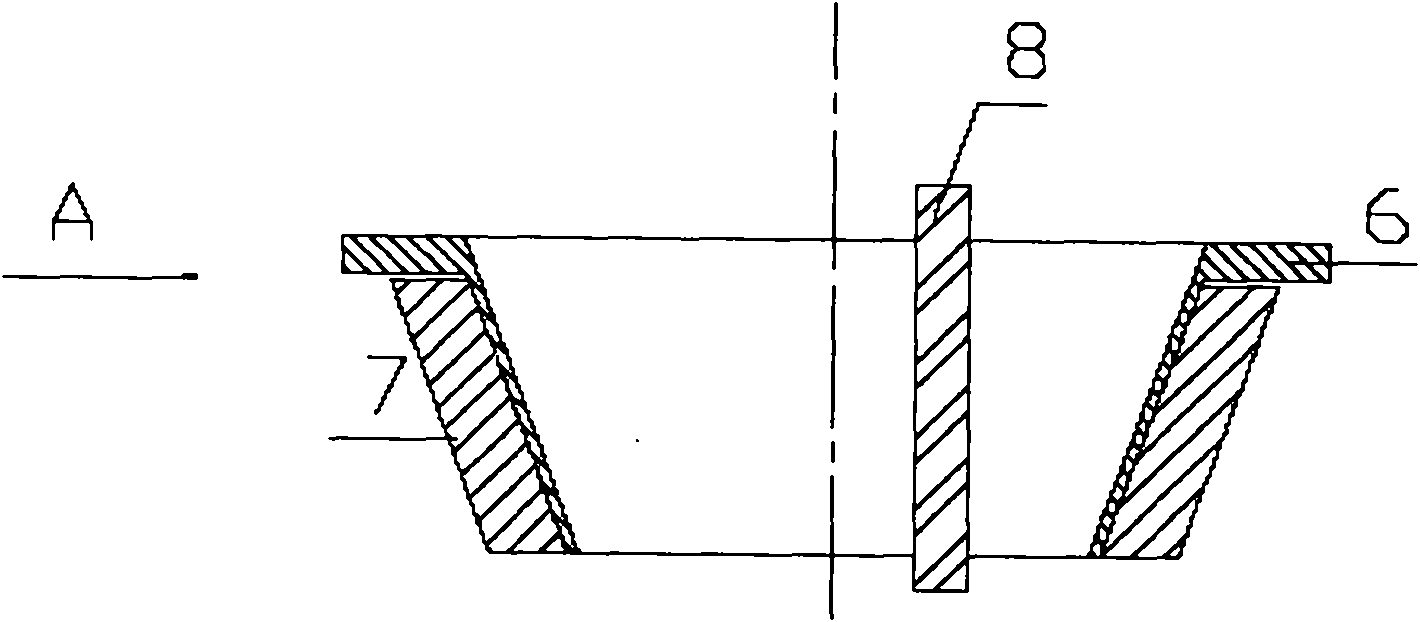

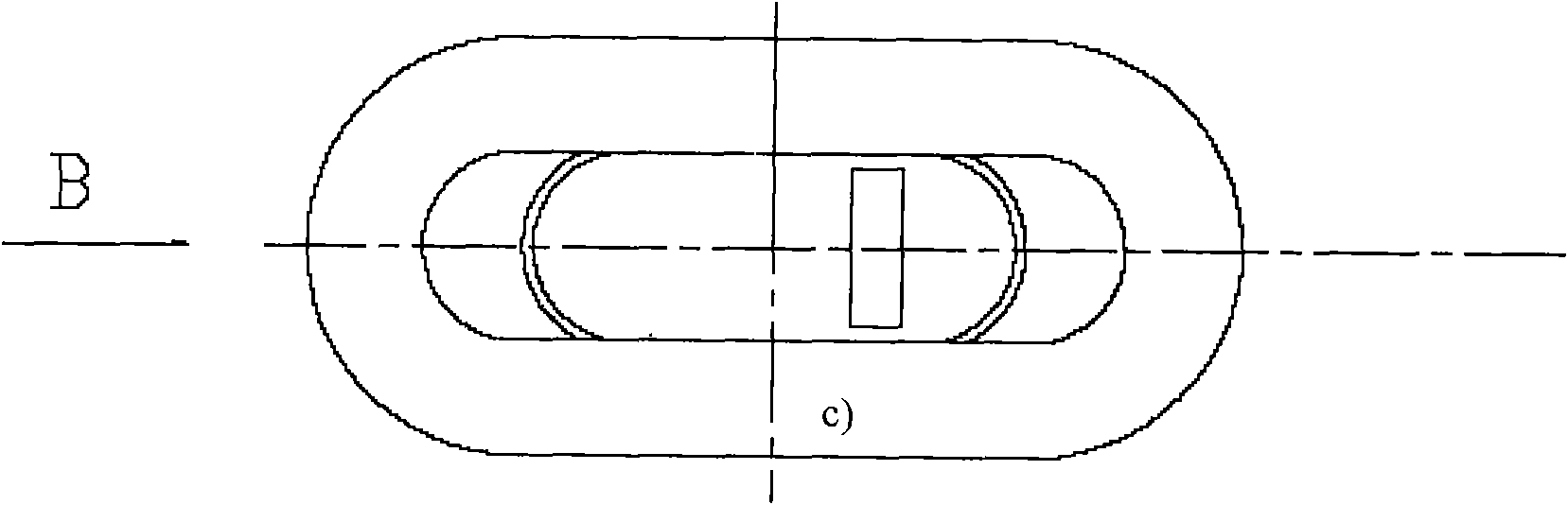

[0019] Such as Figure 1-Figure 4 As shown, the present invention includes: an excitation coil insulation framework 6, an excitation coil winding 7 wound on the framework 6, a magnetic core 8 is installed in the framework 6, and the magnetic core 8 is clamped on the welding torch 1, and the up and down displacement can be adjusted in time; Wherein, the magnetic core 8 is made of soft magnetic material, and the insulating frame 6 is made of resin or Bakelite with certain strength and hardness. When the excitation coil winding 7 is passed through the excitation current, a magnetic field is generated around the coil winding 7. Since the magnetic core 8 has a high magnetic permeability, the magnetic field generated by the coil gathers in the magnetic core 8, and the magnetic induction intensity in the magnetic core 8 also increased. Therefore, compared with not adding a magnetic core, a larger magnetic induction intensity can be produced at a lower excitation current and coil tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com