Preparation method of adenosine triphosphate coenzyme insulin freeze-dried powder injection

A technology of adenosine triphosphate coenzyme and insulin, which is applied in the direction of freeze-drying transportation, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc. It can solve the problems of poor product stability, long freeze-drying time, and collapsed appearance, and achieve Good clarity, stable product quality and full appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

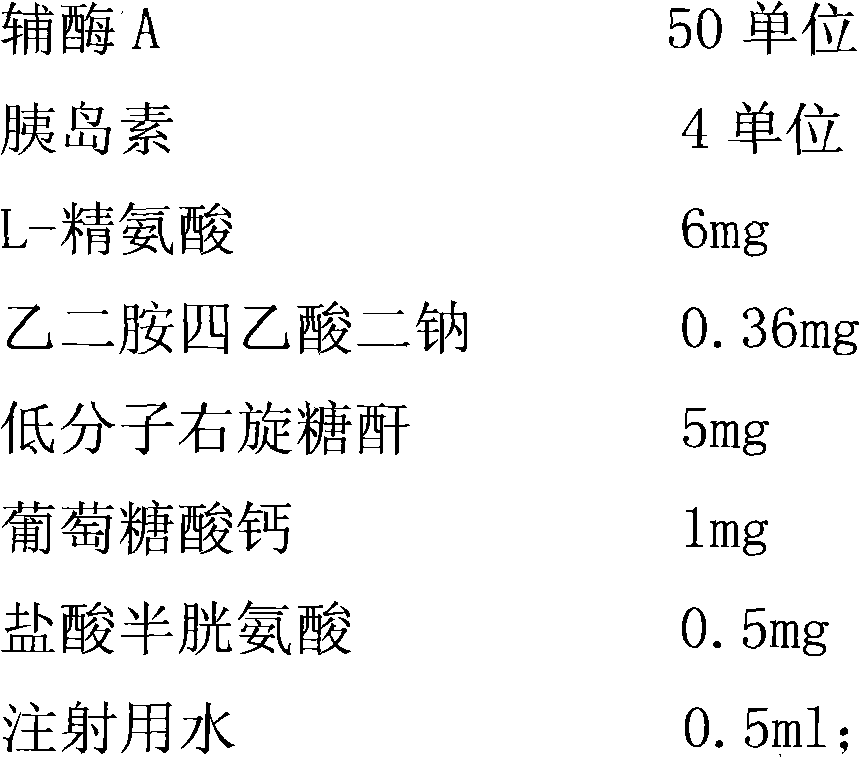

[0023] Weigh the main ingredient and auxiliary materials according to the following process formula:

[0024]

[0025] The specific preparation process is:

[0026] (a) Add an appropriate amount of water for injection into the stainless steel barrel, adjust the pH value to about 2.5 with 10% hydrochloric acid, add insulin, stir evenly, and prepare solution I for later use.

[0027] (b) Add an appropriate amount of water for injection into a stainless steel bucket, add L-arginine and EDTA, stir evenly, add 2% (g / ml) activated carbon and stir for 30 minutes, and decarbonize. Add disodium adenosine triphosphate, stir evenly, and prepare solution II for later use.

[0028] (c) Add an appropriate amount of water for injection into a stainless steel barrel, add calcium gluconate, low molecular weight dextran, and cysteine hydrochloride, add 2% (g / ml) activated carbon and stir for 30 minutes, decarbonize, and prepare solution III for later use.

[0029] (d) Pour the above thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com