Device for detecting qualifying diameter dimensions of shafts

A technology for detecting shafts and dimensions, applied in the direction of mechanical diameter measurement, etc., can solve the problems of increasing production costs of manufacturers, inconvenient installation, and failure to find out in time, and achieve the effect of eliminating production accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

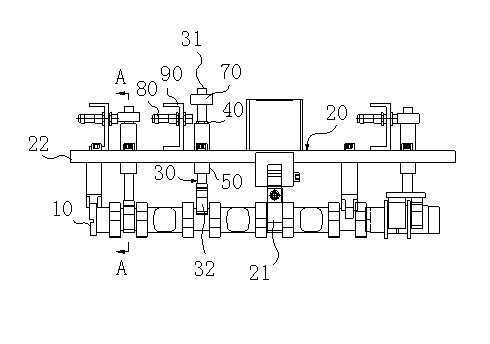

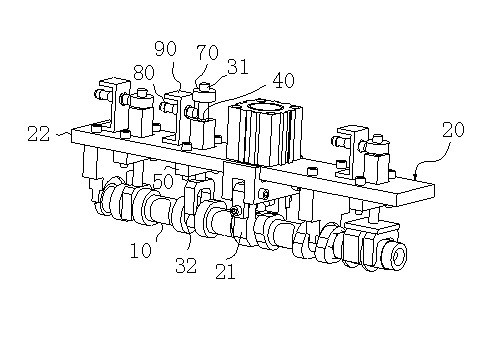

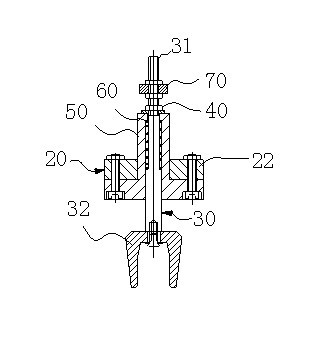

[0016] A device for detecting qualified diameters of shafts, including a positioning mechanism 20 for positioning with the measured shaft 10, the device also includes a measuring piece 30 that can move linearly, and the measuring piece 30 translates along the guide mechanism 50, the The measuring part 30 is provided with a reference part, and the axis distance from the reference part to the measured shaft 10 coincides with the standard value of the radius of the measured part of the measured part 10, and the device also includes a limit mechanism 40 for limiting the nearest position of the measuring part 30 ,like figure 1 and figure 2 shown.

[0017] As a further preferred solution of the present invention, the measuring piece 30 includes a measuring rod 31 and a clip 32 arranged at one end of the measuring rod 31, and the opening direction of the clip 32 points to one side of the component to be measured, such as Figure 1-4 As shown, the clip 32 here is similar to the bay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com