Enhanced heat exchange device for sinter of circular cooler

A technology for strengthening heat exchange and ring cooler, applied in the field of iron and steel production, can solve the problems of energy waste, low flue gas temperature of ring cooler, low flow rate at high temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

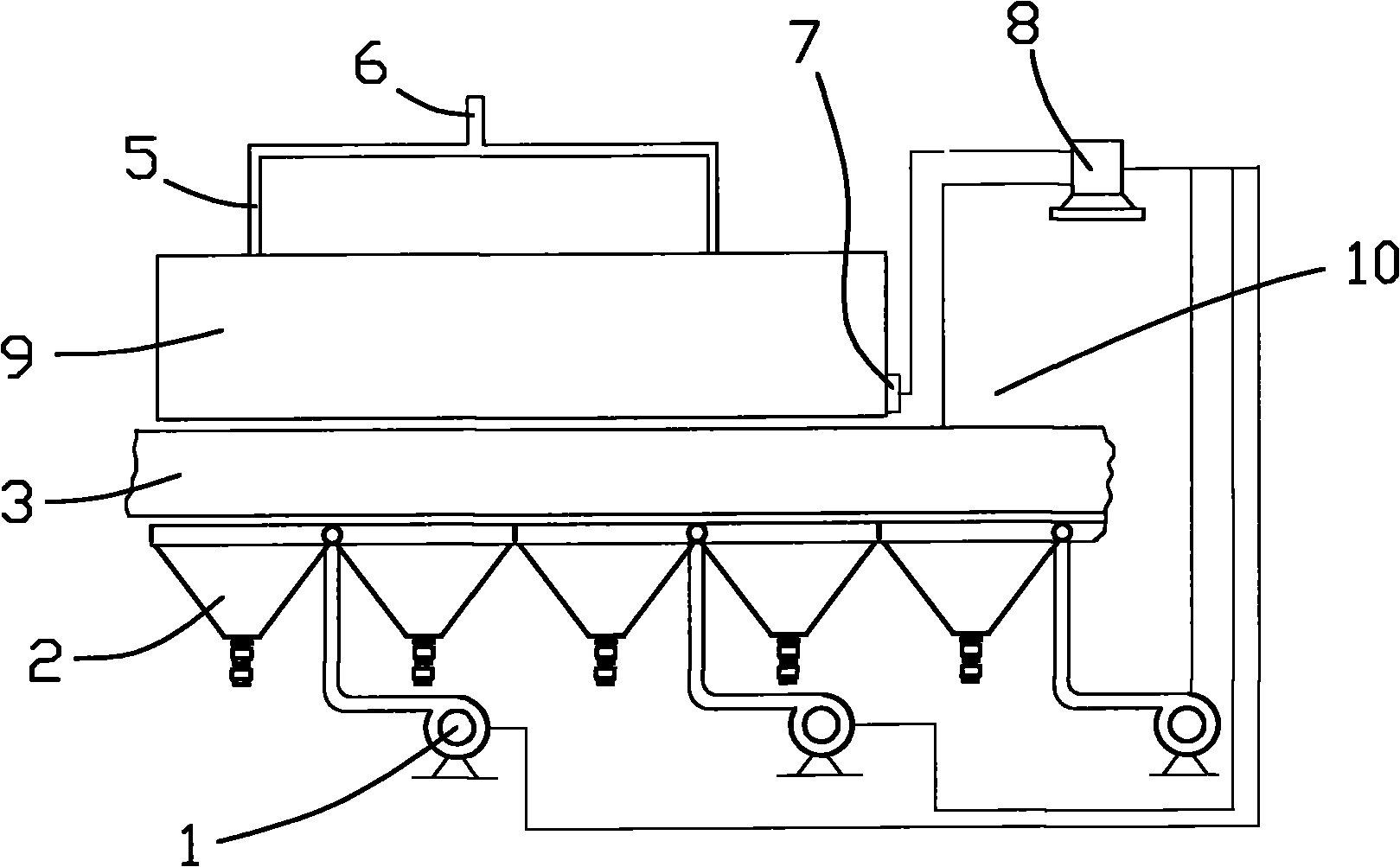

[0015] Such as figure 1 , figure 2 As shown, the embodiment of the present invention provides an enhanced heat exchange device for the sintered ore of an annular cooler, which includes: a variable frequency blower 1, an annular cooler 2, a trolley 3, an enhanced air chamber 4, an annular cooling cover 5, and smoke Air pipe 6, temperature sensor 7, control device 8.

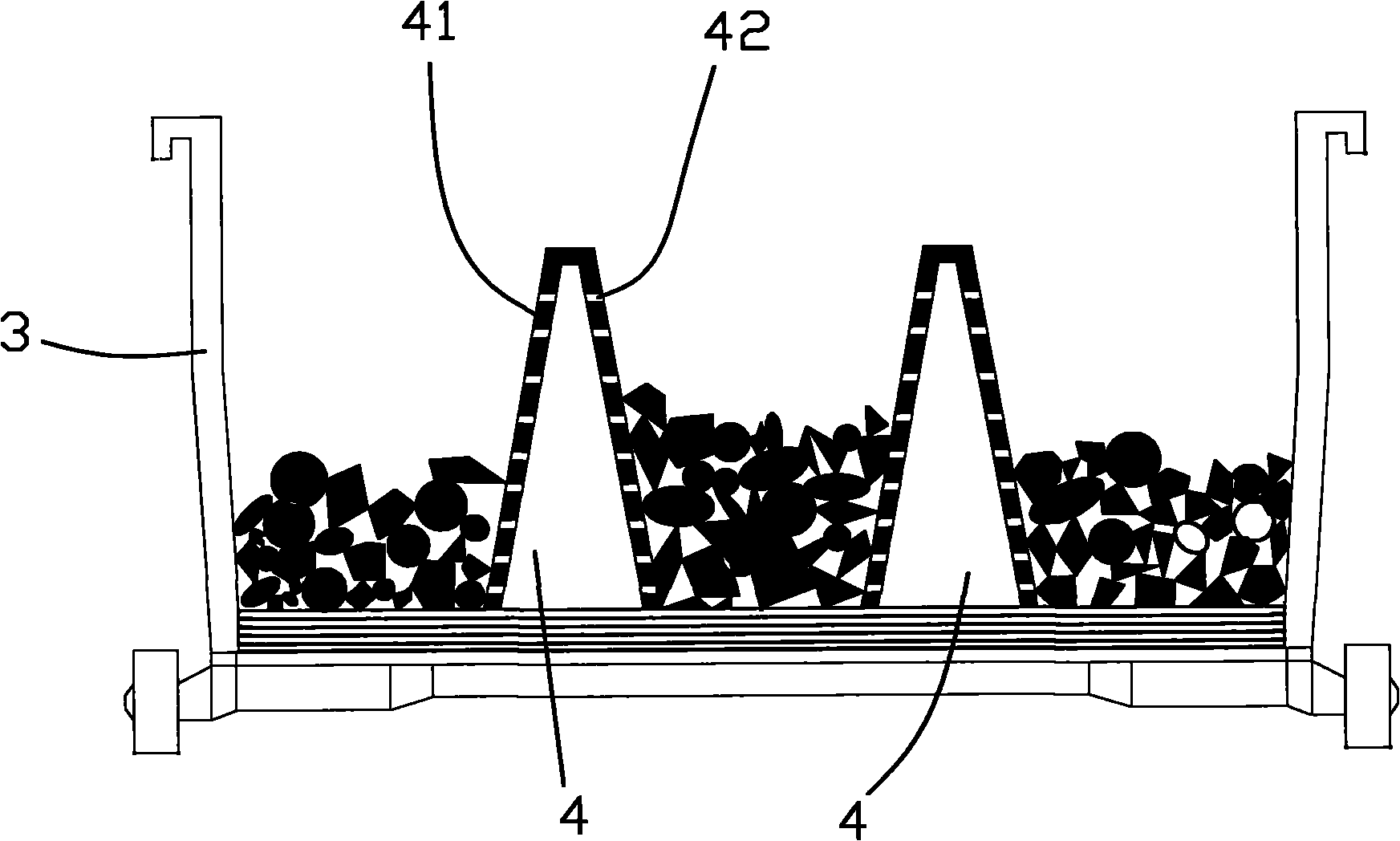

[0016] The trolley 3 is used to carry the sintered ore. The bottom of the trolley 3 is provided with an annular cooler 2 and the bottom of the annular cooler 2 is provided with a frequency conversion blower 1; the enhanced air chamber 4 is set in the trolley 3, and the trolley 3 is provided with an annular cooling cover 5. The annular cooling cover 5 is provided with a flue gas pipe 6 communicating with a waste heat boiler (not shown in the figure). The reinforced air chamber 4 is composed of 2 or 3 baffles 41, which are in a herringbone or trapezoidal structure, and the cross-sectional area is not more than 15% of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com