Method and device for recovering metallic lead from lead plaster of waste lead-acid storage battery

A technology for waste lead-acid batteries and lead-acid batteries, which is applied to the improvement of process efficiency, photography technology, instruments, etc., to achieve the effect of simple method, simple structure and continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

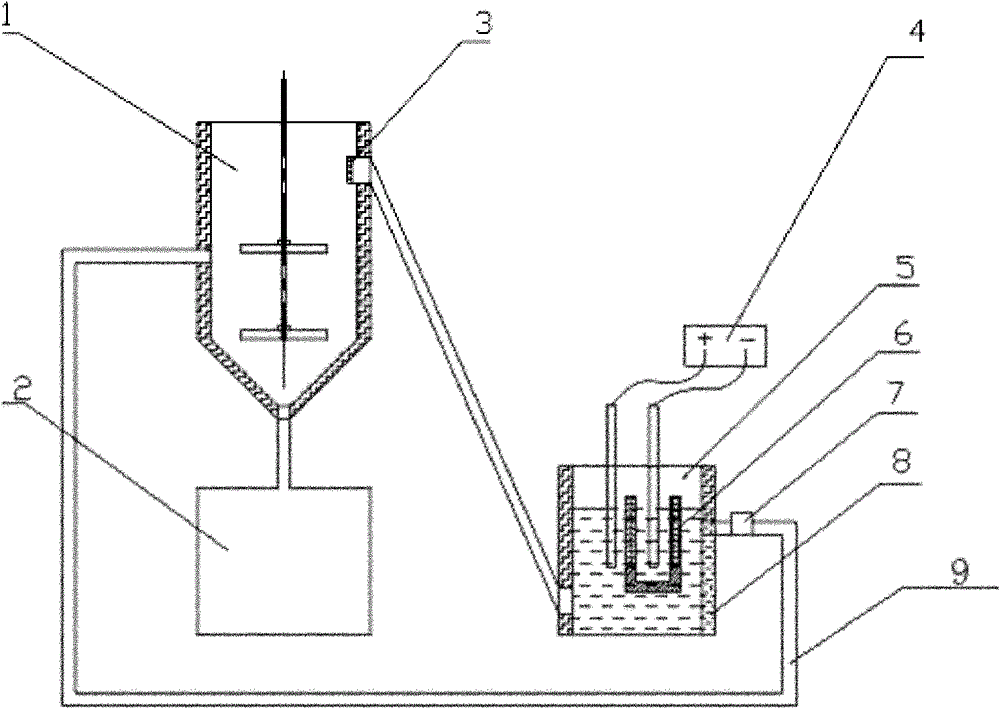

Method used

Image

Examples

Embodiment 1

[0023] Mix 10kg of lead-acid battery lead paste with 10kg of lead-acid battery’s waste sulfuric acid and then roast. The roasting temperature is 150℃, and the roasting time is 4h; put the roasting sand into the stirring tank; add 0.1m tap water 3 To, stir the roasting sand; add calcium acetate concentration to 100g / L, acetic acid concentration to 75g / L, nitric acid concentration to 50g / L, turn on the solution circulation system pump, make the immersion liquid circulate in the electrolytic tank and stirring tank, and leaching the roasting sand , Leaching temperature is 50℃, leaching time is 1h; add bone glue to a concentration of 0.1g / L, β-naphthol concentration is 0.05g / L, electrolysis lead at 50℃, cathode current density is 1A / dm 2 ; Electrolysis 5h. The cathode recovers lead and the anode recovers lead dioxide, and the current efficiency is 97.1%. The residue is filtered by a filter press to obtain deleaded residue, and the filtrate is recycled for recycling.

Embodiment 2

[0025] Mix 10kg of lead-acid battery lead paste with 10kg of lead-acid battery’s waste sulfuric acid and then roast. The roasting temperature is 280℃, and the roasting time is 1h; put the roasting sand in the stirring tank; add 0.1m tap water 3 To, stir the roasting sand; add calcium acetate concentration to 200g / L, acetic acid concentration to 50g / L, nitric acid concentration to 75g / L, turn on the solution circulation system pump, make the immersion liquid circulate in the electrolytic tank and stirred tank, and leaching the roasting sand , Leaching temperature is 40℃, leaching time is 2h; add bone glue to a concentration of 0.2g / L, β-naphthol concentration is 0.5g / L, electrolysis lead at 40℃, cathode current density is 0.5A / dm 2 ; Electrolysis 5h. The cathode recovers lead and the anode recovers lead dioxide, and the current efficiency is 98.9%. The residue is filtered by a filter press to obtain deleaded residue, and the filtrate is recycled for recycling.

Embodiment 3

[0027] Mix 10kg of lead-acid battery lead paste with 10kg of lead-acid battery’s waste sulfuric acid and then roast. The roasting temperature is 200℃, and the roasting time is 2h; put the roasting sand in the stirring tank; add 0.1m tap water 3 To, stir the roasting sand; add calcium acetate concentration to 150g / L, acetic acid concentration to 100g / L, nitric acid concentration to 100g / L, turn on the solution circulation system pump, make the immersion liquid circulate in the electrolytic tank and the stirred tank, and leaching the roasting sand , The leaching temperature is 30℃, the leaching time is 3h; add bone glue to a concentration of 2.5g / L, β-naphthol concentration is 0.01g / L, lead electrolysis at 30℃, cathode current density is 5A / dm 2 ; Electrolysis 5h. The cathode recovers lead and the anode recovers lead dioxide, and the current efficiency is 98.1%. The residue is filtered by a filter press to obtain deleaded residue, and the filtrate is recycled for recycling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com